Davey Malaysia / Home / Water Pump / Davey DynaDrive Water Pump

Davey's DynaDrive Inverter Water Pump

Key features:

- Inverter pump (variable frequency drive) type.

- Suitable for larger households (3-7 shower heads with 5-10 pipes).

- For showering, running taps, & garden use.

- 24 months warranty for pump, motor & controller.

(24 + 6 additional months with e-Warranty scheme) - Adjustable pressure setting based on usage.

- At least 50% energy-saving (water & electricity) water pump.

All Versions of Davey's DynaDrive Inverter Water Pump

Overview Of Davey's DynaDrive Inverter Water Pump

For its price-to-value, the DynaDrive is the most versatile water pump developed by Davey yet! Developed as a compact all-in-one inverter electropump that offers everyday flow that is consistent, the automatic speed drive varies depending on the intensity of watering use, and this enables the DynaDrive to be efficient in design that saves both on hydration and electric utility while remaining quiet in operation. In addition, to maintain a strong performance in its variable cycle of use (as well as long-term running), the DynaDrive centrifugal pump is built with hydraulic parts in complete stainless-steel to prevent emerging rust.

Davey’s DynaDrive inverter water pumps are categorised internally to be known as ‘HPS’, or Home Pressure System, and this is done in a demeanour to describe its motor fitting for all sizes of household use.

Two DynaDrive Water Pump Variations Introduced

| Water Pump Model: | DynaDrive 5 Stage | DynaDrive 6 Stage |

|---|---|---|

| SKU | DD60-10 | DD90-11 |

The grand difference separating Davey’s DynaDrive water pump types fall back in the rigidity of its impellers found, which is deemed as five and also six stages. These numbers found equates internally as also having five or six impellers within, and with each addition calls forth for a stronger flow rate. The performance found between the two water pump models further vary, which is explained meticulously and also tabulated.

Inverter Water Pump Identification Method

A united methodology of identifying Davey’s DynaDrive inverter water pump is practised, and this is used as a means to determine any of the represented model available. Beginning through:

1) A double-digit depiction of the DynaDrive electropump. In this case, the ‘DD’ as can be seen.

2) This is followed by the volumetric flow rate in Litre per minute.

3) The power output of this inverter pump under kilowatt.

Basing on the image as an example, the DynaDrive centrifugal pump found here is the DD60-10; this very series of inverter pump creates a flow rate of 60 litres per minute that consumes up to 1 kilowatt in that frame of output, marking a significant favor of environmentalism as users can still enjoy a jetting splash.

Within every branch and infrastructures assembled by Davey Water Products, this unique identifier remains active from the start to finish as a key tracing number just so orders are meticulously fulfilled, and that an already used DynaDrive inverter pump for numerous years can be sent back for investigative repairing means.

It should also be said that all product code identification will never be changed anywhere, which levels Davey’s integrative culture of manufacturing water pumps to be recognisable no matter the time and age of use.

Attachment

8 Litre Pressure Tank

Constant pressure system of Davey’s DynaDrive electropump is attained through the leveling maintenance of a water tank, and this is routed by the storing mechanism storing up to 8L (270.512 fl oz) of water. Whenever a faucet piping becomes opened, or when a toilet’s flush becomes used, the pressurized hydration found within the tank will flow out to maintain the desired consistency, and this also prevents sudden drops in pressure.

Pump cycling elimination: The vanity of having a water pump with the absence of a pressure tank would result in incredible wear and tear under the resulting start-stop habits of use, whereas with it would offer a beneficial buffering state. This would lead to DynaDrive’s reducing need to on and off effectively throughout any day.

Energy conservation: How energy-saving is obtained is by the eventual cutback of the DynaDrive water pump’s activation, which trims away inessential current utilisation. Alongside less start-stop occurences, your water system becomes even more efficient upon running.

Certifications Achieved

To meet regulatory standards, a few accreditations have been acquired for DynaDrive’s water pump whether to manufacture, sell country-wide, meet consumers’ safety, and/or to export globally as Davey adheres to customs’ requirement. These certifications have further aid to verify Davey’s credibility, promoting more users’ trust, as well as ensuring that everyone’s wellbeing is considered.

SGS Testing: The DynaDrive water pump has been tested for home appliances as Davey commits to meet electrical safety standards. Things like incidental shock, short-circuiting and fires are examined in conduct, as well as verifying if our electropump is well-insulated and grounded.

European Standards (ES): One of the pre-requisite necessity to meet Europe’s import admission, the DynaDrive water pump is also submitted for European Standards’ inspection to determine if our products meet household safety.

International Electrotechnical Commission (IEC): The global governance and benchmark of all electrical, electronic and relatable technologies. All Davey’s DynaDrive centrifugal pump versions are met to ensure it is aligned with the world.

Standards Australia: This endorsement signifies the home electronics’ safety approval of a non-governmental, independent and not-for-profit organisation for the DynaDrive.

Standards New Zealand: A governing regime responsible for directing national grading solutions, wherein Davey have met in order to export this water pump successfully.

ISO 9001: The 9001 numeric for International Standards for Organisation entails for an observation in manufacturing evenness and quality for all of Davey’s products, including and guaranteeing that the DynaDrive water pump production during any period for the supply chain is made in uniformity.

ISO 14001: The 14001 numerical certificate establishes Davey Malaysia and Davey Water Products’ commitment to environmentalism, where in-house as well as production line’s debris are observed to be recycled, whereas lightings and route planning for delivery are eco-friendly to reduce greenhouse emission.

Motor Powered With Variable-Frequency Drive (VFD)

Variable-frequency drive, VFD, or even inverter drive, is an accessorised controller in-synced with the motor attached onto Davey’s DynaDrive water pump in a bid to automatically control the speed. This is achieved systematically through frequency adjustment under an electrical power source, which guides to an accurate precision level during the pump’s operation. As a result, water pressure at different requirement is fulfilled instead of producing a constant one at all running.

Energy-savvy: Davey’s DynaDrive centrifugal pump operates in necessary speed to meet the demanded output, consequentially saving up unintentional electrical consumption.

More than 200 starts per hour: The number of motorised starts that Davey’s DynaDrive electric pump is capable of doing reaches more than 200, effectively doubling the majority of our competitors found in the current marketplace.

Reduced wear and tear / softer start-stop: Slow and steady acceleration or decrease in pump speed lessens the stress found in the water pump’s mechanical parts, equally enlivening the DynaDrive for long-term viability.

High ambient temperature-resistant: With the production of heat upon active usage, as well as being installed across the equator recognised for its humidity and all-year hot weather, this water pump uses an inverter drive built to be tolerant against high heat action.

High-voltage (V) resistance: Varying at different voltage strengths depending on application period, the DynaDrive is tolerant against high charges of electric tension regardless.

DynaDrive's Controller Setting

An automatic pump controller can be utilised and is highly configurable to oversee the preference of maximum pressure found. With a blue LED display, the electro-technology features an alarm system to monitor if no-flow were to occur, which would instigate a complete halt towards the water pump as a fail-safe protection. This safety process is also known as dry running protection to keep the impellers and other inner compartment elements safe from its own impending damage (due to the lack of water flow then).

Fitting DynaDrive Inverter Water Pump Onto A House

An infographic developed by Davey Malaysia’s in-house engineers have pinned the necessary variables required to fit the right water pump for any place of residence, which results in getting the correct DynaDrive version needed for your very own dwelling.

DD60 and DD90 from the visual image represents Davey’s DynaDrive centrifugal pump models of 5 and 6 stages respectively.

Depending on the building, a water pump for any double and 3 storey house would shift the electrician contractor and/or homeowner to be getting the larger alternative.

1.25 Inch of Inlet Sizing For Efficient Housing Flow Rate

Primarily, the most crucial aspect to one’s lodging is the appropriate availability of water source. Davey’s DynaDrive water pump features 1 and a quarter inch (31.75mm) inlet to help increase its flow rate as clean fluid becomes sucked in.

In the occasion where the household uses a 1 inch (25.4mm) channel, for installation convenience a connector can be attached from the tube and to the home booster pump for effective usage.

Matching between inlet measurement and the capacity of Davey’s water pump must always be achieved in a manner to prevent any cavitation from happening, and all the while would it maintain peak efficiency as a constant pressure system.

Net positive suction head (NPSH): The aftermath of Davey’s DynaDrive electric pump being capable of sucking water in completely and without any formation of air bubbles is due to having the stated inlet dimension.

Friction is also reduced within the pipes as the DynaDrive’s inlet has a larger diameter, equally reducing wear and tear and also maximising flow rate.

Faster self-priming: Entering a vacuum status within the tubing becomes a lot quicker just as the bigger water pump’s inlet siphons out every single air, before it becomes dampened in priming. This also contributes to DynaDrive’s dry running protection.

Stainless Steel Volute Casing

One of the key components behind every water pump found available is the front casing, Also known as the volute casing, this has been invented to guide the water flow moved by the impeller itself into the feed for end consumption usage.

Another fact as an understatement is that with the volute casing on, this would further help to convert velocity energy of the water twirled within into pressure of the DynaDrive water pump. SUS304 composite alloy is used to resist against harsh conditions, rust, as well as providing undeterred strength where the water pump remains far superior than any forms of plastic-injection moulding.

Even water distribution: The shape remains advantageous in drawing uniformity of water flow to the DynaDrive water pump’s outlet. The steady guidance of water through the volute prioritises that hydration exits even more smoothly, preventing unnecessary pressure surges or flow inconsistency that can ultimately damage any centrifugal pump.

Control and support: A definite structural rigidity for the electric pump exists, aiding to keep the impellers and other internal components in its fixed position. Meanwhile, many of the moving elements are supported to ensure the DynaDrive pump operate reliably and efficiently.

Internal parts protection: External debris, fine dust particles, and/or contaminants are prohibited from penetrating into the water pump, allowing a protective barrier to aid the DynaDrive’s internal parts to function. Exceeding heat or stress is also regulated, seeing where water (h2o) is circulating within it.

Aiding priming: As water is directed to move unidirectionally, Davey’s DynaDrive water pump aids to retain water inside to allow an appropriate suction to take place.

Stage Bodies Fitted For Impellers & Diffuser

Fitting the various sequences of impellers and diffuser into stationary placement, the stage body, also known as a protection bracket, is the internal and middle section responsible to drive fluid for a rigid pressure increment in a water pump. This becomes realised only when h2o passes from one series of its compartment to another, and is the imminent force to carry the DynaDrive electropump to constantly raise pressure when needed as a water system.

Within this water pump itself, there lies the protection brackets of 1st stage, 2nd, additional inner stages (depending on DynaDrive’s iteration model), as well as the final one according to orderly arrangement. And each of these installations will enclose the stated parts mentioned.

Closed Stainless Steel Impeller Design

SUS304 impeller is also added and used for practical longevity among the DynaDrive centrifugal pumps. In contrast to plastic, the metallic impeller allows for higher performance application as it swirls the water much faster. This is tailored to internal piping infrastructure for bigger housing, higher counts of faucets and/or running taps, and ultimately requires a stronger pressure.

Closed impeller refers to its invention of being both sides completely sealed. This is used within every variants of the DynaDrive built as intended in its blueprint for homes, producing a stronger pressure needed with the water pump than a semi-open impeller could.

Corrosion-resistant: The propelling device attached to the shaft within will endlessly be in contact with your raw Malaysian water source. Thus the result of wear and tear—not just externally, but also internally within the DynaDrive h2o pump. To apprehend that from causing eventual disaster, these impellers are made composite metal mixture for corrosion resistance.

Lower maintenance: Lesser overhaul is needed with the DynaDrive electric pump is due to the result of it inherently running only on clean liquids, bringing less to no clogging at all for its complete operation.

Backplate With Mechanical Seal Secured

The backplate is installed as a rear pillar of support for Davey’s DynaDrive water pump. Serving to uphold the mechanical seal, a clip spring and a washer in-place, the distribution of water is additionally routed properly from the impeller and into the discharge outlet as intended.

Motor protection: Another integral aspect is that the backplate would serve as a tertiary protection against the spillage of water, preventing it from entering the electric motor of a pump. This ultimately puts a stop from electricution, unnecessary damage of DynaDrive, and also unsafe water supply.

Shaft support: The rotating machine element that is stationed internally in a water pump has the backplate as a support, putting an emphasis that this core component does not go out of alignment regardless of the usage time.

O-Ring Sealed, Spacer And Washer For Fricition-Reduction

The inside parts of Davey’s DynaDrive water pump are sealed with O-rings securely to inhibit any leakage of water. Made in EPDM (ethylene propylene diene monomer rubber), these can be found in its volute casing, and one to suit within the variable-frequency drive’s adaptor.

Spacers are added for the much-needed gaps in-between internal parts, just so it doesn’t grind against each other with inessential water pump’s wear and tear. To align every other sections into the correct positioning within is also another function that is carried out by the spacers, and this includes the rotating shaft, and the impellers within the water pump.

As a flat and a miniature round rubber piece, the washer is the last of these internal elements inside the water pump applied to seal completely, minimise friction generated, and even scatter pressure across the different parts of the pump assembly. As it’s polymer-made, operating noises are absorbed into the hydrocarbon material to reduce noise also, making a perfect assembly for household use.

Operating Limits of Davey's DynaDrive Inverter Water Pump

| Models | DD60-10 (CE) | DD90-11 (CE) |

|---|---|---|

| Model | DD60-10 | DD90-11 |

| Max. flow rate @ 300 kPa | 60L / min (16 US gallons) | 92L / min (24 US gallons) |

| Max. flow rate @ 400 kPa | 48L / min (13 US gallons) | 72L / min (19 US gallons) |

| Max. flow rate @ 500 kPa | 32L / min (8 US gallons) | 35L / min (9 US gallons) |

| Max. casing pressure | 1,000 kPa (145 psi) | |

| Max. set pressure | 600 kPa (87 psi) | |

| Min. cut-in pressure | 10 kPa (gauge pressure) (1.5 psi) | |

| Default cut-in pressure | 50 kPa (7 psi) less than set pressure | |

| Max. cut-in pressure | 20 kPa (3 psi) less than set pressure | |

| Operating water temperature range | 0 – 80°C (32 – 176ºF) | |

| Operating ambient / air temperature range | 0 – 50°C (32 – 122ºF) | |

| Nature of fluids | Clean, clear, non-corrosive, non-flammable liquids with no fibers and little sand / silica or abrasives (maximum concentration 40 g/m3) | |

| Applicable approvals |

| |

| Applicable approvals (Global versions) |

| |

| Applicable approvals (US versions) |

| |

*L within the table refers to Litre.

*kPa unit refers to Kilopascal.

*The °C unit symbol refers to degree celsius.

*UNE is the abbreviation for Spanish Association for Standardisation.

*IEC is the short naming form of International Electrotechnical Commission.

*AS/NZS is Standards Australia / Standards New Zealand achievement.

*Gallons is a measurement from the United States for liquid capacity.

DynaDrive's Materials of Construction Table

| Part | Material |

|---|---|

| Casing | 304 stainless steel |

| Impellers | 304 stainless steel |

| Stages (casing) | 304 stainless steel |

| Pump shaft | 316 stainless steel |

| Stage centring device | 304 stainless steel |

| Mechanical seal | Carbon / ceramic |

| O-rings | Ethylene propylene diene monomer (EPDM) |

| Plugs | 316 stainless steel |

| Motor shell and lantern bracket | Aluminium with baked polyester powder coat finish |

| Motor drive | Xenoy |

| Fan cowl / rear foot (DD60-08, DD60-10, DD90-11) | Polypropylene |

| Adaptor VSD | Polypropylene |

| 5-way tee piece | 304 stainless steel |

| Pump coupling to 5-way tee piece | Brass |

DynaDrive Centrifugal Pump's Electrical Data

| Models | DD60-10 (CE) | DD90-11 (CE) |

|---|---|---|

| Voltage | Estimated 220 – 240V | |

| Max motor speed | 2,900 rpm | |

| Frequency (incoming power) | 50 – 60 Hz | |

| Input power P1 | 1.1 kW | 1.3 kW |

| Output power P2 | 0.8 kW | 0.9 kW |

| Running current | 7.4 A | 8.6 A |

| Insulation class | F | |

| IP rating | 55 | |

*Voltage uses a symbol known as V.

*Revolution per minute is shortened to RPM.

*kW is defined as kilowatt.

*A is the symbol for Ampere.

*IP rating stands for ingress protection rating.

DynaDrive's Hydraulic Performance Data Sheet

| Models | DD60-10 (CE) | DD90-11 (CE) |

|---|---|---|

| Inlet (BSP F) | 1.25″ / 31.75mm | |

| Discharge outlet (BSP M) | 1″ / 25.4mm | |

| Pressure tank outlet (top) (BSP F) | 1″ / 25.4mm | |

| Default nominal operating pres | 400 kPa | |

| Number of stages (impellers) | 6 | 5 |

| Max. pump pressure | 64m | 56m |

| Default tank pre-charge pressure (Optional extra on CE variants) | 280 kPa | |

*BSP F interchanges British Standard Pipe Female.

BSP M swaps British Standard Pipe Male.

*The symbol ” is the inch equivalent.

*Milimeter is shortened to mm.

*kPa is known as kilopascal.

*CE refers to Conformite Europeenne.

DynaDrive's DynaDrive DD60 QH-Curve

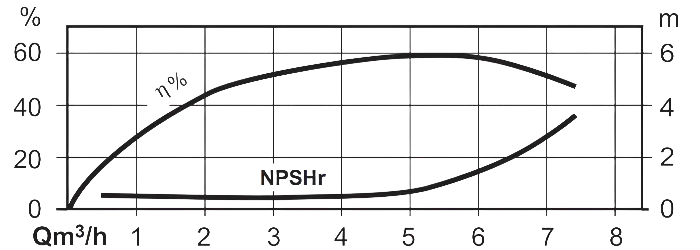

DD60 Pump Efficiency And NPSHr Curve

DynaDrive's DynaDrive DD90 QH-Curve

DD90 Pump Efficiency And NPSHr Curve

*lpm represents litre per minute.

*The N% curve signifies efficiency rating.

*NPSHr is also known as Net Positive Suction Head rating.

*Qm3/h is abbreviated from cubic metre cube per hour.

Included In The Box

DynaDrive Inverter Water Pump

8 Litre Pressure Tank

User Manual

Proof of Purchase

24 Months of Manufacturer Warranty (Increased by Another 6 Months with e-Warranty Scheme)

All Grouped Household Water Pumps

Contact Us