Davey Malaysia / Home / Water Pump / Engine Water Pump

Engine Water Pump In Grouped Product View

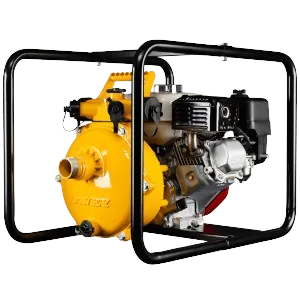

Fitted with a diesel or petroleum (gasoline) engine as the core motor to pressurise, take the stretch of challenges anywhere with Davey’s selection of engine-driven pumps. Dewater and/or ration where electric-based motor can’t.

Engine Water Pump In Individual Product View

Firefighter Engine Water Pump

Engine Water Pump by Davey

Fitted all motorised generator requiring gasoline (petrol) or diesel as its primary source of fuel, Davey’s Engine Water Pump assortment catalogues the ideal machinery choice needed to pressurise your hydration. The distinctive energy application needed to run the engine water pump is designed for the other angle of the market capitalisation, where one half falls upon the reliance of electropumps, whereas the rest retreats to the traditional source of fueling via non-renewable energy use. With the uniqueness of combustion processing, the engine pump carries out to take watering beyond, away from the common grounds of civilisation and free from the reliance of electricity by constraint. And especially true in arid lands, mountainous terrains and thickened areas of forestry, the limited construction for power supply is what makes the engine centrifugal pump used at its most-sought peak.

Our headquarters, Davey Water Products Pty Ltd, also feature this saying of our motor pump that has went through hell and then back again, because of its regime in being used during emergency moments, as well as for cooling system available. And to add icing on the cake, the engine water pump category has been with us ever since our founding days, making a successful regime across time—testified by users—within the century.

Localised Fuel Source

Davey’s engine water pumps can be characteristically chosen to fit its required fuel source towards a regional consumption means, allowing for anywhere energy replacement access to continue the cycle of irrigation. Within a continent, the types of hydrocarbon usage barely changes, and the proper motor pick remains the perfect fit throughout the cycle of your engine pump use.

Gasoline (Petrol): In most regions – including Malaysia, gasoline has been the essential combustible energy that is driving machines, making the same gas-driven engine water pump the right choice. It is also important to know that both gasoline-type and oil pump virtually means the same thing, with the exception that North Americans defined it as ‘gas’ in its fossil fuel description, whereas in Commonwealth nations, this would be known as petrol.

Diesel: The other counterpart to crude oil and electric-driven units. Diesel-based motor centrifugal pumps are always in demand, and these tend to be the most sold variants found in Davey’s collection. The capacity of diesel promotes a more stringent firepower upon ignition, and with the heavier hydrocarbon composition, the burning offers higher torque that equates to the engine water pump having stronger irrigating power.

Electrical Outage-Proof

Whenever water pumps (also known as electropumps) that are reliant on voltage supply faces a scenario where a city/state/nation-wide shortage of electricity happens, the limitation of current-operated pumps will then become prominent. As voltaic sending becomes halted, so also the usage of centrifugal pumps found.

This leads to the loss of pressure and even the potential stop of water transfer, creating the lack of pressure, loss of production, clogs and even floods that can prove a nuisance (or even endangering) to the public.

Alternatively, this is also where the engine water pump shines. With its carbon fuel expenditure, the substitute contraption can be deployed to save lives, or save the day, making the engine water pump an any moment and anywhere back up. However, it should also be kept in mind to regularly check the centrifugal pump’s performance and start-stop ability, ensuring that when the call of duty were to come, the gadgetry is capable of answering and fulfilling demands whenever situation arises.

Automobile & Chiller Pumps Similarity

Functionally, Davey’s engine water pumps can be said to be no different than centrifugal pumps found within any cars, trucks and/or motorbikes seen, or even within the chiller. This is because these pumps can function similarly to circulate coolants within a particular cooling system.

Automobile: The only minor difference that separates the car engine pump with a regular water pump is the pistons that exists on its build, even though the steady pump starts and processing remains identical. The non-electric vehicle would be powered off the combustion of fossil fuel no different than Davey’s engine water pumps, with the exception that the sizing of the horsepower differ – having the centrifugal pump iteration being far milder.

Chiller Pump: In the case of chiller pumps, the same principle of carrying cold water in and removing hot water out into the cooling tower holds true of the same pressurisation. Typically found among event spaces, HVAC, industrial processing, and even data centers (due to the tremendous software processing that heats up the internal ambience), these chiller pumps are energised by the generator set, which in turn could use coal, petroleum, or even plugging to continue operations.

The similar concept of engine water pump is often observable in these variety of illustration described.

Centrifugal Pump For First Responders

From the hindsight of Davey Malaysia, we have found that the relationship of engine water pumps can be said to be the main equipment for fire brigades, emergency rescuers, as well as first responders. This is especially true as crisis happens in the neck of the woods, and our fluid pump can be seen fastened up as though it’s a field marshal, or your brethren-in-arms, at the frontline of life-saving dedication.

Always Ready: The mechanism of Davey’s collection of engine water pumps have always been finalised and well-put together. Because of this, no additional setups are needed, other than directly carrying the force pump itself and to add fuel if there isn’t any. A convenient handle can be seen for this version of Davey’s category, allowing better mobility and enhanced grip as the search and rescue members carry any of the engine water pump type across the incidental plain. And with things completely put together and in an ever-ready status, this leads to lesser pump failure with incompatible fittings all over.

Portability: Convenience is the emphasis found with fossil fuel where it can be carried anywhere to jump start the portable petrol water pump. Because of this widespread understanding, Davey’s tool collection have been carried into practice and it goes worldwide.

The release of the engine water pump is like the brethren-in-arms at the frontline, and in the spur of the moment the machine can help to alleviate the pyros of bushfire crisis, or the drought of the summer that can lead to wildlife destruction, making it a mechanism of miracle for the greater good.

Lightweight: While as rugged as the engine water pump can be, the materials science in application is well-considered for its transportation ease. To ensure durability for long-term action, anodised aluminum becomes used for its endurance while trimming down heft, making all of Davey’s engine water pumps selection easily carried by a fire man, or a paired team member.

Refueling On-The-Go: Whenever the engine water pump is exhausted of its combustible juice, a temporary halt can be done to refill it once more just so firefighting against the disaster can be realised. Simply have a small gallon by your side at all times as a reserve to reload Davey’s gasoline water pump.

Multipurpose

Like any electropumps, the said application for Davey’s engine centrifugal pump assortment is no different when it comes to versatility. This multipurpose usage is seen by the interest and field of one’s use, which has enabled the motor pump to be discovered almost anywhere. For example:

Agricultural Fields: In acres and hectares of land stretching from one end of the farmlands to another, big diesel engine water pumps are often found in the terrains for agriculture work. This is because electric-based centrifugal pumps can only cover so much of a distance due to the length of its circuitry, whereas the engine water pump can take the farmer anywhere and whenever he wants for irrigation. Enclosed ponds and wells in remote places may be created to draw aquatic dampening, and as the engine pump becomes attached, the fittings can fill for drip irrigating means.

Firefighting: One further aspect that the employment of Davey’s engine driven pumps are often found and can be synonymous with, is the essence of fire combat. The endeavour and ordeal that was seen throughout wildfires made the requirement of distant firefighting, and this takes relief workers and all of Davey Malaysia’s engine water pumps in almost any sector. In fact, our diesel pumps are also named after Firefighter as Davey is known to answer the port of call.

Dewatering In Construction: Whenever excavations are done, or when foundations are built, the engine pump can also substitute a submersible one for dewatering reasons and to clean debris to ensure a clean framework for development.

As A Slurry Pump: During the cleanage of sewage waste, or potentially within mining operations, Davey’s engine water pump can be assigned to take on the role of pushing out slurry. The mineral combination, alongside mud, sands, and/or stones are what makes the slurry somewhat heavy (and likely viscuous), and this will require a stronger pump of about 5 hp, 10 hp, or even 12 hp (horsepower) at most for pressure. In the same instance, as mining process is done, the methodology of dewatering with Davey’s engine water pump can be achieved.

Municipal Water Fulfillment: This is the crucial part where drinking water is obtained, and where situational engine centrifugal pumps can be observed in practice within treatment facilities. As always, raw aquatic source will first be sucked in and pressurised by the internal impellers to be discharged into the silos for filtration, and this keeps the production of clean water molecule in large volumes to be continuously producing.

Flood Control: Another findings centred to the employment of any engine water pump is the real-time operation of managing floods, and this migration of water helps to reduce swamping, which can save lives and reduce unnecessary machinery damages found.

Rated Number One In Firefighting Across All Water Pumps

Coincidentally, a poll was casted among Australians to determine the most sought-after centrifugal water pump that would be favoured for both industrial and manual use, and the unbiased voting returned with Davey being rated as the number one with the utmost trusted brand for firefighting, as well as for water transfer.

Attach And Extinguish: This is as simple as it gets – by plugging into the fire hydrant, or hose into the natural lake, blue river stream, well, and/or other aquatic source to draw out hydration force, this is to gush down emerging blaze with the belief system of our beautiful brand to bring a better cause.

90+ Years Since Founding: Quality is what Davey has continuously strived for, and the resulting boon across the scores of years is the recognition of our engine water pumps. The acknowledgement and stability was what made Davey trustworthy, elevating our pump to its winning grandeur.

Motor Types In Engine water Pumps

With up to 5 different product lines encompassing Davey’s series of engine water pumps, it should be said that each of these items can have 11 different engines, making a line of 55 possible variations to be chosen from.

Each of these motors hold a different torque and power to drive the pump (as well as to move aqua within), that when it’s converted on the pistons connected to the crankshaft (which is further linked into the pump’s shaft itself), your chosen diesel pump’s impeller will then begin spinning. Unlike car engines, no timing belt is found wrapped around a pulley to transfer the necessary torque.

With Davey Malaysia, 2 renowned brands are collaborated with to create our engine water pumps’ assortment, and these are:

Honda: The world has known of this logo as being an iconic car maker with the likes of Civic, Jazz, and City as some of its line of vehicle manufacturing, but little does most know is that they also manufacture petroleum and diesel-based pumps. These iterations of Honda water pumps are a lesser offshoot of the existing car segment – having seen as a means to diversify their machinery production line in order to increase their end of the market share revenue.

Yanmar: The fabled Japanese diesel engine and heavy vehicle manufacturer. Although tractors, harvester, and excavators are Yanmar’s specialisation, the creation of fossil fuel water pump types are also within their reach. This trails down to us having the Yanmar brand as part of our motor provider, creating additional divergence and more choices of Davey’s engine water pumps.

TEFC Motor

All mechanical components of the engine water pump are TEFC motor (also known as totally enclosed, fan-cooled motor) kept by design, and the absolute coverage keeps moisture and/or liquids from accessing the internal components to prevent unnecessary damage. The hard shell is plastic injection moulded and it remains as a core function to prevent eletrocution. Besides that, the resilient hardness keeps external exposure from breaching into the piston and other motor parts of any engine water pump itself.

Harsh Environment Resistant: Understand that each of these are the backbone and tools-in-arm for the disaster relieving teams, and as such, all of Davey’s engine water pumps are brought in any time and anywhere whenever summoned. And to endure so, the casing is durable to resist against harsh environments. In windy atmosphere, dusty terrains or corrosive exposure, the TEFC housing shelters the engine centrifugal pump and remains ideal for the brisk of the outdoors.

Waterproof: The contraption of any engine water pump itself is a paradoxical phenomena. On one hand, this is needed to create pressure across liquids supplied, which seems to say that all pumps will love hydration being drawn in. On the other, direct wetness into the engine itself will pose a very terrible risk and potential destruction, leading towards a total enclosure of the engine water pump’s casing.

Aerodynamical Cooling: As the overall motor is completely shut-off, it must be known in mind that the plastic injection moulding of the pump’s casing is made to be as aerodynamical as possible, enabling for efficient cooling internally. The fan that would turn within would prevent overheating, altogether extending the engine water pump’s lifespan.

Maintenance-Free: Where foreign debris becomes absent, the TEFC motor would also help in reducing maintenance because of the nigh-cleanliness within the pump itself, and the only fluid found would be lubricants that are needed to keep the motor pieces from rubbing against each other crudely.

Throughout every parts and bits found in this variant of water pumps, a lot of materials science and security protocols are placed to protect the engine itself. This is because it is the most expensive component found when compared to any other engine water pump’s component, that when a replacement becomes sought, the pricing remains equivalent to a new pump on its own.

Engine Capacity / Displacement

Like autocars, for any assortment of engine water pumps (and not just the Davey brand), the strength of its output tends to be quantified in terms of Cubic Centimeter (cc) for motor capacity instead of horsepower (hp) in conventional instance. Each of Davey’s engine water pumps will feature diffferent performances and also variable cc in capacity, and in that regard, the fluids being discharged will have a flow rate of different Litre per minute (or LPM in abbreviation) individually.

Occasionally, a layman may still find a pump manufacturer for ‘a 5hp diesel water pump’ in that regard, yet the stated strength can be interchangeable into cc by calculation means.

The output developed is based on the motor sizing, which determines the power as well as torque that generates the operating limits of the engine water pump. In simpler terms, a larger generator area would allow greater room to burn fuel within, and this equates to centrifugal pump’s stronger output. Similar and discerning factors that affects the function of the engine’s capabilities is centred around the design framework for efficient displacement, and this sole case is the reason why Davey has outsourced the manufacturing of the motor itself towards world-renowned manufacturers of Honda and also Yanmar.

Self-Priming Pump

All of Davey’s collection surrounding the engine water pump series have the capacity to be self-priming in status. The self priming pump is a terminology to define that it has the natural tendency to remove contained / trapped air found within, in order to fulfill the internal compartments with liquids as a whole.

With water filling up the internal compartments, it is termed as a net positive suction head (NPSHr) to describe that the pressure intake is far greater than releasing hydration out, just so the pump achieves the status of it being free from cavitation, a phenomena that swirls air and water rampantly that causes miniature and violent bursts that can damage the bits and pieces of the engine water pump, and the self-priming status is an innate mechanism that offers a protection to prevent that, without the need of an external priming.

Marine-Grade Aluminium Construct

For various crucial reasons, the housing of all of Davey’s engine water pumps are built with the selective usage of aluminum as the primary materials science in application. It denotes the significant situational means that is happening during the deployment of the engine water pump:

Durable: The marine-graded aluminum is sturdy to withstand against the continuous move-about and the versatile changes in the terrains, making a long-lasting effort with any from Davey’s engine water pump’s catalogue.

Corrosion Resistance: Because of unprecedented disasters that can occur in any real-time moment, a readily available form of hydration source—whether freshwater or saltwater—must be drawn in through the hose and filtered by the foot valve, in order to extinguish upcoming flames with Davey’s engine water pump. The liquid origin may be of ocean water quality, and this can be murky, incredibly salty in nature, or dirty itself, yet it can be ran onto the centrifugal pump for emergency. As such, the physical resistance of aluminum becomes core to fend against rust.

Lesser Weight: Unlike other forms of metallic alloy, the uniqueness of marine-graded aluminum is that it remains lighter in weight and is the sole reason behind the ease of carrying just so the engine water pump can be transported anywhere.

Replacement Parts In Engine Pumps

It is within Davey Malaysia’s transparent policy and duty to let know that all spare components are subjected to the model of the pump, as well as the availability of the parts itself.

Although having some pieces that are directly acting as the cover from the surface and atmosphere itself (like the volute, gasket or even the O-ring found fastening the suction inlet – as well as the outlet or inner interconnected parts), it must be kept in mind that replacements for these are never meant to be for aesthetic reasons. Instead, bits of any of these are replaced to ensure optimal performance out of the wear and tear from the engine water pump.

With systematic dry running protection not being available, to the potential impairment of the impellers, mechanical seal, diffuser, spacer, washer and so forth can be seen (due to the result of hard water sucked up), these parts becomes another cause to be replaced ever occasionally for the pump. Of course, the attachments of the pressure tank and/or smart pressure switch can be installed as an optional means to the dry running, although it is never recommended (as the engine water pump is meant to be carried around overseas).

To seek for the precise replaceable components, customers are advised to give the serial number of the engine water pump, which leads to Davey Malaysia determining if the existing parts of the machine can be replaced and repaired.

Davey's Engine Water Pump's FAQ

Does a venturi tube exist in any of Davey's engine water pump?

No. The tube is completely absent in all variations of this pump assortment. Hence, to stimulate a jet splashing with venturi effect (following the result of Bernoulli’s principle in imitation) is impossible.

What safety precautions should be taken when operating a water pump at a fire scene?

With Davey’s engine water pump, few safety precautions can be applied during an emergency fire scene. This includes:

- Always having a water source to have a hose draw hydration at all times. This is done to prevent your water pump from dry running.

- Strong pressure generated may require the first responders to work in pairs just so they can lift and control the releasing output.

- Straighten your fire hose right before starting the diesel pump to jet out water on the flames.

- Do not add any fossil fuel into the engine water pump near a raging fire due to the petroleum products’ flammability.

- Consistent centrifugal pump cleaning to replace diesel / gasoline, air and oil filter to ensure it runs smoothly.

- Do not add water in order to clean the petrol tank found on Davey’s engine water pump. Instead, drain the existing oil and add anew.

How do firefighters ensure that the water pump is properly primed before use?

To ensure your engine water pump remain in positive priming state, it is important to have it remain on an even level, or near in position to your source.

A check valve, piping and foot valve must be used to ensure that is achievable.

What is the typical flow rate of an engine water pump, and how does it vary depending on the type?

Flow rates are subjective, and is highly dependent if it’s a single stage or double action type of a engine water pump, which would mean having a singular or twin impeller in its engineering blueprint.

Are there any maintenance need when it comes to keeping the engine water pumps in optimal condition?

Yes. There must be regular maintenance to keep it in its ideal state. The maintenance of the engine water pump lies in replacing certain parts, and these are:

- Air filter.

- Oil filter.

- Fossil fuel.

The gasoline and/or diesel supply must be changed as it can be oxidised in the long run, which hampers usability during crucial periods of need.

What are the key components of a water pump system used by firefighters, and how do they work together?

A complete water system used by firefighters will comprise of:

- An engine water pump

- Discharge outlet

- Control panel (option)

- Pump relief valve

- Hose and nozzle

- Priming system

- Raw water supply

Each of these parts are required individually, yet all of these serve a different purpose.

Firstly, the fire-pump drives the pressure needed as an extinguishing agent, whereas the discharge outlet are segments connecting from one hose to another for the input and output of water force.

For the controller, any fire service personnel may remotely activate or close the firefighter water pump down for convenience, while a pump relief valve is added across the piping system to prevent damaging the diesel pump itself (due to water hammering).

The hose is required to point and water down fire, and this is attached with a nozzle to manually release the pressured h2o itself.

The priming system must be added to prevent air from entering, which may cause cavitation and potential damage within Davey’s firefighter water pump. As for raw water supply, this must be intact to continuously suction out for burn-extinguishing.

How do different engine water pumps such as portable and truck-mounted differ in their operation?

The different types come in their form of accessibility when engaging with catastrophic threats in any of their individual operations.

For example, truck-mounted pumps are integrated into the fire engine itself to draw out stored water to be splashed across the scorching zones. Although being permanently placed into the vehicle may inhibit performance, this is where Davey’s engine water pump comes into effective use.