Davey Malaysia / Home / Water Pump / Davey Firefighter Single Stage Engine Water Pump

Davey's Firefighter single stage engine water pump

Key features:

- Standard automatic pressure system type.

- Suitable for remote irrigation.

- For firefighting, tank-to-tank and high head water transfer, as well as irrigation use.

- 12 months warranty for pump & motor.

- Stable pressure output.

- Quick setup and easy priming up to 6m.

Overview of Firefighter single stage centrifugal pump

Water is one of nature’s most potent forces, and when used appropriately, water becomes an indispensable instrument for protection, productivity, and peace of mind. The Davey Firefighter series of single- and twin-stage centrifugal pumps are designed to make water work more efficiently. These pumps, designed for the most demanding situations, turn ordinary obstacles into feasible jobs, whether you are defending property from fire, transporting water from tank to tank, irrigating farmland, or powering high-pressure applications. Precision engineering lies behind their rugged design, where every piston, cylinder, and volute is built to last, and every motor and cooling system is tuned for constant performance. Whether driven by petrol or diesel fuel, each model exemplifies Davey’s world-renowned combination of mechanical strength and human inventiveness.

Single or twin: choosing your Firefighter

Every water transfer or firefighting application needs a solution specific to its surroundings. Single-stage and twin-stage pumps are available in the Firefighter® range, guaranteeing a balance between powerful pressure and high flow delivery. The single-stage units are compact and cost-effective, perfect for quick water flow applications, such as filling a pool, extinguishing spot fires, or irrigating crops. They employ a basic centrifugal impeller technology that maximises flow while maintaining pressure stability. On the other hand, the twin-stage pumps incorporate two impellers that produce greater heads, providing consistent pressure for boom spraying, long-distance hose runs, or applications requiring additional force.

| Engine Model and Outlet Description | Engine Capacity (cc) | Inlet/ Outlet | Firefighter Single Stage | Product Group | Firefighter Twin Stage | Product Group |

| Honda Petrol Engines | ||||||

| Honda GP160 (3-Way Outlet) | 163 | 1½” / 1½” | 5150HD | 1540 | 1541 | |

| Honda GX160 (4-Way Outlet) * | 163 | 1½” / 1½” | 5155H | 5255H | ||

| Honda GX160 Viton (4-Way Outlet) | 163 | 1½” / 1½” | 5155HV | |||

| Honda GX160 (3-Way Outlet) | 163 | 1½” / 1½” | 5155H3 | |||

| Honda GX200 (4-Way Outlet) * | 196 | 1½” / 1½” | 5165H | 5265H | ||

| Honda GX200 Viton (4-Way Outlet) | 196 | 1½” / 1½” | 5265HV | |||

| Honda GX200 (3-Way Outlet) | 196 | 2” / 1½” | 5165HQ | |||

| Honda GX200 Electric Start (4-Way Outlet) | 196 | 1½” / 1½” | 5165HE | 5265HE | ||

| Honda GX200 Electric Start Viton (4-Way Outlet) | 196 | 1½” / 1½” | 5465HEV | |||

| Honda GX270 Electric Start (3-Way Outlet) * | 270 | 2” / 2” | 5290HE | |||

| Honda GX390 Electric Start (3-Way Outlet) * | 389 | 2” / 2” | 5113HE | 5213HE | ||

| Yanmar Diesel Engines | ||||||

| Yanmar L48N Electric Start Viton (4-Way Outlet) ^ | 219 | 1½” / 1½” | 5148YEV | 1543 | 1543 | |

| Yanmar L70N Diesel Electric Start + Deluxe Frame (4-Way Outlet) ^ | 320 | 1½” / 1½” | 5170YE | 5270YE | ||

| Yanmar L100N Diesel Electric Start + Deluxe Frame (3-Way Outlet) ^ | 435 | 2” / 2” | 5210YE/HP | |||

* These models are fitted with a roll frame.

^ Electric start models DO NOT include batteries, leads, or plate.

Each model is driven by a powerful 4-stroke petrol or diesel engine, with options ranging from compact 5 hp motors for household or light-duty use to bigger cylinders built for industrial durability. Every installation, from agricultural vehicles and tankers to rural homesteads, may benefit from the Firefighter® series’ electric start and recoil choices.

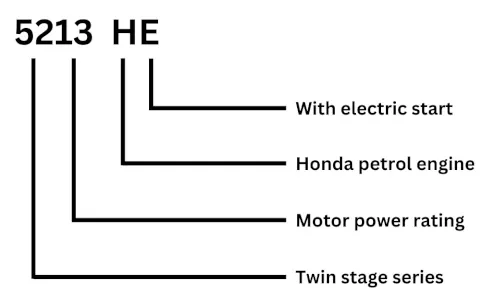

Water pump identification: understanding model numbers

Selecting the right Firefighter® pump is simplified through its logical model coding. Each number and suffix provides a snapshot of its mechanical identity:

- The prefix “51” identifies the single-stage centrifugal pump series, while “52” designates the twin-stage centrifugal pump series.

- The following digits indicate the output power in horsepower (hp).

- The suffix “H” stands for Honda petrol engines, while “Y” stands for Yanmar diesel engines. Where “E” is added, it specifies an electric starter option, while an additional “V” indicates Viton.

Thus, a dependable firefighting unit such as the 5213HE is a twin-stage model with a Honda GX390 petrol motor delivering 13 hp, complete with electric start.

Optional Viton seal kits offer chemical resistance

Optional Viton seal kits improve pump adaptability in chemical applications. The fluorocarbon elastomer Viton is well-known for its ability to withstand heat, chemicals, and wear.

When installed, the seals protect the operator and the pump by allowing the safe pumping of treated water, herbicides, or insecticides. While Viton alternatives guarantee long-term dependability in more challenging circumstances, standard carbon and ceramic seals function effectively in clean water. Because of its versatility, the Firefighter® may be used for agricultural spraying, irrigation, and fire defense.

Certified strength, quality you can trust

The Firefighter® series is built and certified to strict European Union standards, assuring mechanical safety, electrical dependability, and environmental compliance. Every accreditation attests to the pump’s dependability while safeguarding users and the environment.

2006/42/EC (Machinery Directive): Confirms the pump meets essential health and safety requirements for machinery, covering design, operation, and maintenance.

2014/30/EU (Electromagnetic Compatibility Directive): Ensures electric components operate without causing or being affected by electromagnetic interference, vital for consistent motor performance.

2011/65/UE (Restriction of Hazardous Substances): Guarantees restricted use of hazardous materials, making pumps safer and more environmentally sustainable.

2000/14/EC (Outdoor Equipment Noise Directive): Certifies compliance with noise limits for outdoor equipment, reducing environmental and user impact.

2005/88/EC (Amendment to 2000/14/EC): Strengthens noise control requirements and ensures quieter operation in outdoor environments.

Engine and motor for reliable power

Every Firefighter® pump is powered by a meticulously developed four-stroke motor that transforms fuel into reliable hydraulic performance. Each petrol or diesel engine has a precision-balanced piston and a cast-iron cylinder bore for mechanical longevity. While the overhead valve design promotes smooth operation and efficient combustion, low-oil protection guards against harm by stopping the engine before wear can happen. The pump can operate under heavy loads without overheating since the cooling system is tuned for prolonged operation. With options ranging from modest 5-hp engines to high-output 13-hp units, there is a configuration to fit homes, farms, and emergency trucks. While recoil backup ensures dependability even with a dead battery, electric start models offer ease. Combined, these motors provide the robustness, ease of use, and durability demanded in water transfer situations.

| Engine Options | ||||||||

|---|---|---|---|---|---|---|---|---|

| Description | Honda Overhead Valve Petrol Engine Options | Yanmar Diesel Engine Options | ||||||

| 163cc | 163cc | 196cc | 270cc | 389cc | 219cc | 320cc | 435cc | |

| GP160 | GX160 | GX200 | GX270 | GX390 | L48 | L70A/E | L100A/E | |

| Firefighter single stage models | 5150HD | 5155H, 5155HV, 5155H3 | 5165H, 5165HE | – | 5113HE | 5148YEV | 5170YE | – |

| Firefighter twin stage models | – | – | 5265H, 5265HE, 5265HV, 5265HEV | 5290HE | 5213HE | – | 5270YE | 5210Y/E |

| “Out of box” governed max engine speed at no load | 3800 rpm | 3600 rpm | 3000 rpm | 3600 rpm | ||||

| Fuel tank (Litres) | 3.1L | 5.3L | 6.1L | 2.4L | 3.5L | 5.5L | ||

| Running time per tank at full, 3600 rpm | 2.2 hrs | 1.8 hrs | 2.1 hrs | 1.6 hrs | 1.7 hrs | 1.6 hrs | 2.5 hrs | |

| Low oil protection | 2.2 hrs | Yes | No | |||||

| Low oil protection | Yes | No | ||||||

| dBa at full load, 3600 rpm | 85 at 4m | 86 at 4m | 79 at 7m | 78 at 7m | 79.5 at 7m | 80.5 at 7m | 82.5 at 7m | |

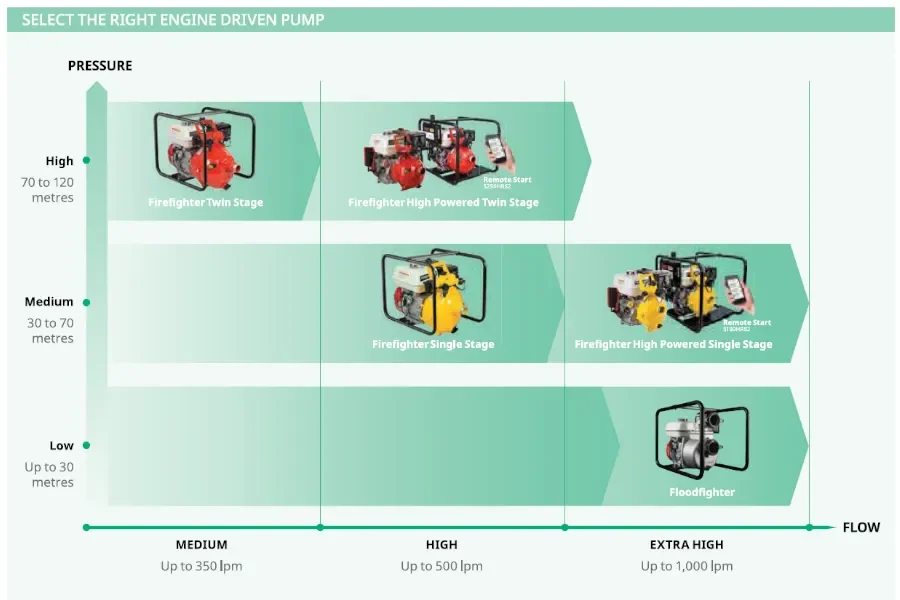

Selecting the right engine drive pump

The Davey Firefighter® single stage pump is a trusted choice for applications needing strong flow with medium pressure, such as tank filling, irrigation, or general water transfer. With performance up to 70 metres head and around 500 lpm flow, it provides a balanced solution for rural properties and farms. For higher pressure demands, the Firefighter® twin stage extends performance to 120 metres, making it suitable for firefighting and boom spraying.

The high powered single stage adds extra capacity for demanding transfer jobs, while the Floodfighter® delivers up to 1000 lpm for large-scale emergencies. Together, these pumps cover every requirement.

Pump housing built for every environment

The Firefighter® pump is made of marine-grade aluminium, which is known for its lightweight yet strong properties. A polyester baked coating protects every surface, providing corrosion protection against severe weather, pool water, and ocean spray. The housing ensures safe and dependable operation by holding the volute, impellers, and seals under pressure of up to 1600 kPa. Despite its robustness, the portable housing makes the pump ideal for trucks, farms, and irrigation sites. The housing resists wear thanks to the precise balancing act between robustness and simplicity, allowing for a constant service life in various demanding applications.

Impellers to drive flow and pressure

Both the impeller and volute are the mechanical components of the centrifugal pumping process, converting motor power into water movement. Firefighter® pumps use wide-vane impellers of marine-grade aluminium, combining excellent efficiency and durability. The clamped impeller design in single-stage variants makes maintenance easy and obstruction removal simple.

A second impeller is added to twin-stage machines to increase head pressure, guaranteeing dependable operation for tanker, irrigation, and firefighting applications where elevation and distance are essential considerations. The volute is precision-cast to optimise the flow route, reduce turbulence, and increase delivery efficiency.

Mechanical seal and neck rings protect longevity

Pump durability is determined by sealing systems that protect essential components. The carbon and ceramic mechanical seal in Firefighter® pumps are designed to tolerate abrasive water and prevent shaft leaks. This is enhanced by patented floating neckrings, which preserve effectiveness while minimising wear. While the rear neckring prolongs engine and seal life by lowering shaft stress, the front neckring minimises water recirculation.

In addition to improving dependability, this design helps prevent damage during brief dry runs. The seal and neckrings work together to provide meticulous engineering that maintains the pump’s smooth operation throughout irrigation, firefighting, or general transfer tasks.

Included In The Box

Firefighter Engine Water Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us