Davey Malaysia / Home / Water Pump / Davey Firefighter Two Stage Engine Water Pump

Davey's Firefighter twin stage engine water pump

Key features:

- Standard automatic pressure system type.

- Suitable for remote irrigation.

- For firefighting, tank-to-tank and high head water transfer, as well as irrigation use.

- 12 months warranty for pump & motor.

- Stable pressure output.

- Quick setup and easy priming up to 6m.

Overview of Firefighter twin stage engine water pump

In rural estates, farms, and towns where water is essential, the appropriate pump may make the difference between safety and vulnerability. Reliability is crucial for controlling bushfires, transporting water between tanks, and maintaining irrigation lines. Farmers, emergency workers, and property owners all rely on the Davey Firefighter® twin stage engine pump.

This high-performance machine blends tough mechanical engineering with a functional design. The Firefighter®, with its centrifugal dual impeller design, self-priming capabilities, and dry-running protection, strikes a balance between high head, strong flow, and ease of use. Its marine-grade aluminium volute and housing are polyester-coated to withstand drops, splashes, pool water, and sea spray, ensuring a long service life even in challenging conditions.

Most notably, it offers a wide choice of Honda petrol four-stroke engines and Yanmar diesel engines, allowing users to select the right balance of portability, torque, and endurance.

Choosing the right Firefighter twin stage for every application

Every water transfer in a firefighting situation has unique requirements, and the Firefighter® twin stage engine pump is available in several configurations to meet these needs. Each model features the same proven twin impeller design, providing increased head pressure while maintaining consistent flow. This design makes it ideal for long hose runs, boom spraying, and demanding firefighting applications.

| Engine Model and Outlet Description | Engine Capacity (cc) | Inlet/ Outlet | Firefighter Single Stage | Product Group | Firefighter Twin Stage | Product Group |

| Honda Petrol Engines | ||||||

| Honda GP160 (3-Way Outlet) | 163 | 1½” / 1½” | 5150HD | 1540 | 1541 | |

| Honda GX160 (4-Way Outlet) * | 163 | 1½” / 1½” | 5155H | 5255H | ||

| Honda GX160 Viton (4-Way Outlet) | 163 | 1½” / 1½” | 5155HV | |||

| Honda GX160 (3-Way Outlet) | 163 | 1½” / 1½” | 5155H3 | |||

| Honda GX200 (4-Way Outlet) * | 196 | 1½” / 1½” | 5165H | 5265H | ||

| Honda GX200 Viton (4-Way Outlet) | 196 | 1½” / 1½” | 5265HV | |||

| Honda GX200 (3-Way Outlet) | 196 | 2” / 1½” | 5165HQ | |||

| Honda GX200 Electric Start (4-Way Outlet) | 196 | 1½” / 1½” | 5165HE | 5265HE | ||

| Honda GX200 Electric Start Viton (4-Way Outlet) | 196 | 1½” / 1½” | 5465HEV | |||

| Honda GX270 Electric Start (3-Way Outlet) * | 270 | 2” / 2” | 5290HE | |||

| Honda GX390 Electric Start (3-Way Outlet) * | 389 | 2” / 2” | 5113HE | 5213HE | ||

| Yanmar Diesel Engines | ||||||

| Yanmar L48N Electric Start Viton (4-Way Outlet) ^ | 219 | 1½” / 1½” | 5148YEV | 1543 | 1543 | |

| Yanmar L70N Diesel Electric Start + Deluxe Frame (4-Way Outlet) ^ | 320 | 1½” / 1½” | 5170YE | 5270YE | ||

| Yanmar L100N Diesel Electric Start + Deluxe Frame (3-Way Outlet) ^ | 435 | 2” / 2” | 5210YE/HP | |||

This variety of options ensures that, whether the pump is placed on a tanker, situated on a farm, or kept ready for emergency response, there is a Firefighter® twin stage engine pump configured for the task.

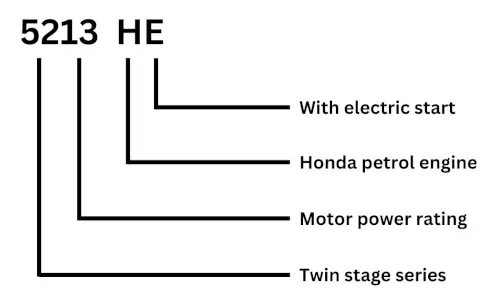

Pump model code identification

Firefighter® twin stage pumps feature unambiguous model labelling that makes selecting the correct one easy.

Each prefix, number, and suffix conveys the pump’s primary mechanical and engine identity:

- The prefix “52” designates the unit as a member of the twin-stage centrifugal pump series.

- The following figures represent the engine output in horsepower (hp).

- The suffix “H” refers to models with Honda petrol engines, where “Y” refers to models with Yanmar diesel engines.

- An addition “E” indicates the presence of an electric starter option, while an additional “V” indicates compatibility with Viton seal and O-ring kits.

For example, the 5213HE is decoded as a twin-stage centrifugal pump powered by a 13-hp Honda GX390 petrol motor with an electric start mechanism.

Accessories

Optional Viton seal kits provide chemical resistance for agricultural use

Viton seal and O-ring kits are optional and can be used for specialised tasks, such as spraying insecticides or herbicides. Viton elastomers have higher chemical resistance than ordinary nitrile rubber, assuring seal integrity even when subjected to strong agricultural sprays or fertiliser solutions.

These kits enable the Firefighter® twin stage pump to be used for crop protection, weed management, and boom spraying with chemical additives, in addition to water transfer. Viton kits increase service life, lower maintenance costs, and maintain pump dependability in agricultural applications by avoiding chemical deterioration of seals and O-rings.

Roll frames and kits provide stability and adaptability in the field

To increase adaptability, the Firefighter® twin stage pump may be used with a variety of frames and accessory kits. Deluxe frames are compatible with poly pumps, including the current Firefighter® petrol and twin-stage variants, and feature a pumping plug adapter for a ¼ BSP thread.

A deluxe frame kit is available to equip both high-powered single and twin petrol or diesel engine variants, with optional buffer kits to enhance stability and protection during tough operations. Deep well injector kits come in 4’’ and 5’’ body diameters and include foot valves, drive pipe hose barbs, and optional jet or venturi assemblies for various applications.

Engine and motor for reliable power

Every Firefighter® twin stage pump is powered by a robust 4-stroke engine, available in both petrol and diesel variants. The petrol variants offer a wide range of power outputs, ensuring that there is a model to suit every application, from light-duty agricultural use to heavy-duty firefighting and irrigation. For those who prefer diesel, the alternative offers strong torque, excellent fuel efficiency, and endurance for longer operation in isolated areas. Each motor is designed with a strong cast iron cylinder bore, an efficient piston design, and an integrated cooling system to provide dependability under load. You can choose between a recoil and electric start, ensuring the pump starts the first time.

| Engine Options | ||||||||

|---|---|---|---|---|---|---|---|---|

| Description | Honda Overhead Valve Petrol Engine Options | Yanmar Diesel Engine Options | ||||||

| 163cc | 163cc | 196cc | 270cc | 389cc | 219cc | 320cc | 435cc | |

| GP160 | GX160 | GX200 | GX270 | GX390 | L48 | L70A/E | L100A/E | |

| Firefighter single stage models | 5150HD | 5155H, 5155HV, 5155H3 | 5165H, 5165HE | – | 5113HE | 5148YEV | 5170YE | – |

| Firefighter twin stage models | – | – | 5265H, 5265HE, 5265HV, 5265HEV | 5290HE | 5213HE | – | 5270YE | 5210Y/E |

| “Out of box” governed max engine speed at no load | 3800 rpm | 3600 rpm | 3000 rpm | 3600 rpm | ||||

| Fuel tank (Litres) | 3.1L | 5.3L | 6.1L | 2.4L | 3.5L | 5.5L | ||

| Running time per tank at full, 3600 rpm | 2.2 hrs | 1.8 hrs | 2.1 hrs | 1.6 hrs | 1.7 hrs | 1.6 hrs | 2.5 hrs | |

| Low oil protection | 2.2 hrs | Yes | No | |||||

| Low oil protection | Yes | No | ||||||

| dBa at full load, 3600 rpm | 85 at 4m | 86 at 4m | 79 at 7m | 78 at 7m | 79.5 at 7m | 80.5 at 7m | 82.5 at 7m | |

Tested to ensure safety, quality, and reliability

The Davey Firefighter® twin stage engine pump is designed to operate under pressure and is certified to meet stringent European Union standards. These certifications indicate not just mechanical and electrical dependability, but also environmental stewardship and user protection.

2006/42/EC (Machinery Directive): Confirms that the pump has been designed and produced to fulfil important health and safety criteria for machinery, including operation, service, and long-term reliability.

2014/30/EU (Electromagnetic Compatibility Directive): Ensures that the electric start system and other electrical components operate without interference and are resistant to electromagnetic disturbance, resulting in constant motor dependability.

2011/65/UE (Restriction of Hazardous Substances): Limits the use of hazardous substances in construction, ensuring that the pump is both safer for users and more ecologically friendly.

2000/14/EC (Outdoor Equipment Noise Directive): This certification confirms that the pump complies with noise emission regulations for outdoor equipment, thereby reducing operator fatigue and environmental noise impact.

2005/88/EC (Amendment to 2000/14/EC): Strengthens noise control regulations, resulting in quieter and more acceptable operation in residential, agricultural, and emergency response situations.

These certificates demonstrate that the Firefighter® twin stage is not only powerful and efficient, but also safe, compliant, and responsible in terms of design and operation.

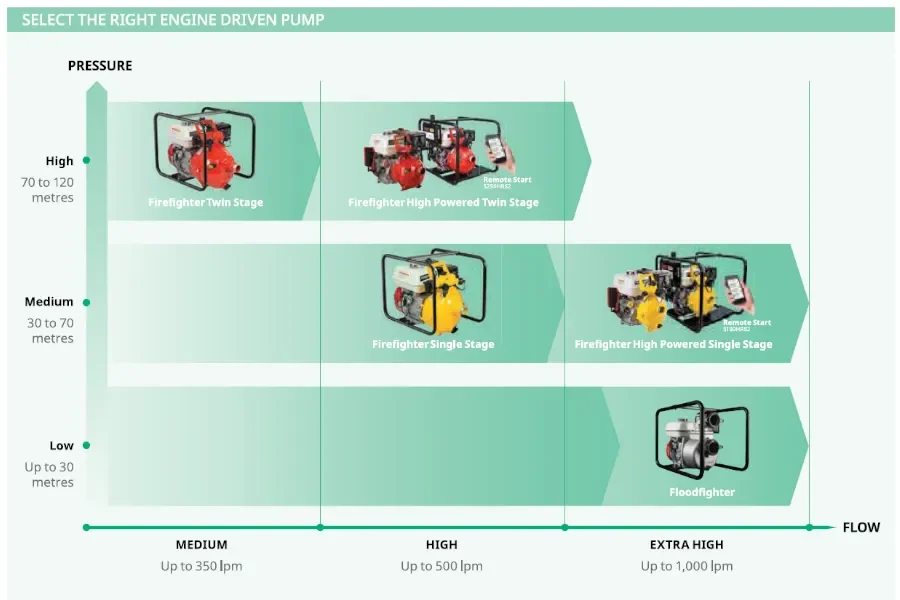

Selecting the right engine-driven pump

Davey’s engine-driven range offers solutions for every water challenge, with each model designed to strike a balance between flow and pressure. The Firefighter® twin stage stands out for delivering high pressure of up to 120 metres. Making it ideal for long hose runs, boom spraying, and demanding firefighting duties.

For higher flow with medium pressure, single-stage and high-powered single-stage units provide dependable performance for irrigation and rapid water transfer. At the top end, Floodfighter® pumps achieve extra-high flow rates of up to 1000 lpm, making them perfect for large-scale emergencies. This spectrum ensures there is a reliable option for every situation.

Corrosion-resistant pump housing ensures a long service life

Every Firefighter® twin stage pump features a durable, marine-grade aluminium casing. The casing, diffuser, and yoke are meticulously manufactured and then coated with a baked polyester powder to prevent corrosion. This dual protection guards against drops, splashes, pool water, and even exposure to sea spray in coastal areas.

The system is secured with stainless steel and zinc-plated fasteners, and extensive priming and drain plugs provide easy access for service. Designed for long service life, the pump housing is robust yet lightweight, allowing the Firefighter® to be portable while withstanding harsh field conditions.

The impeller and volute deliver a strong flow with lasting efficiency

The Firefighter® twin stage pump features a centrifugal dual-impeller design that delivers high head and powerful flow simultaneously, making it ideal for firefighting and boom spraying applications. The impellers are thrust balanced, which reduces engine load and increases motor life. They are enclosed within a precision-cast volute constructed of marine-grade aluminium that has been polyester-coated for further corrosion protection

This combination provides resilience to hostile conditions, including ocean spray, agricultural pesticides, and sediment-laden water. The pump’s use of two impellers in series ensures consistent pressure over extended distances, making it ideal for firefighting, irrigation, and transferring fluids from tank to tank.

Mechanical seal protects performance and extends service life

The Firefighter® twin stage design prioritises durability, featuring a carbon/ceramic mechanical seal that ensures leak-free performance even under variable pressures. This seal protects the pump’s housing and engine bearings from premature wear and tear. Davey’s innovative floating impeller neckrings are installed both front and rear to complement the seal.

The front neckring increases hydraulic efficiency by reducing internal recirculation losses, and the rear neckring preserves the seal by limiting abrasive intrusion. Together, they provide smoother operation, improve component life, and guarantee that the pump functions reliably in firefighting, irrigation, and heavy-duty water transfer applications.

Included In The Box

Firefighter Engine Water Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us