Davey Malaysia / Home / Water Pump / Davey Floodfighter Engine Water Pump

Davey's Floodfighter engine water pump

Key features:

- Standard automatic pressure system type.

- Suitable for remote irrigation.

- For firefighting, tank-to-tank and high head water transfer, as well as irrigation use.

- 12 months warranty for pump & motor.

- Stable pressure output.

- Quick setup and easy priming up to 6m.

Overview of Davey's Floodfighter engine water pump

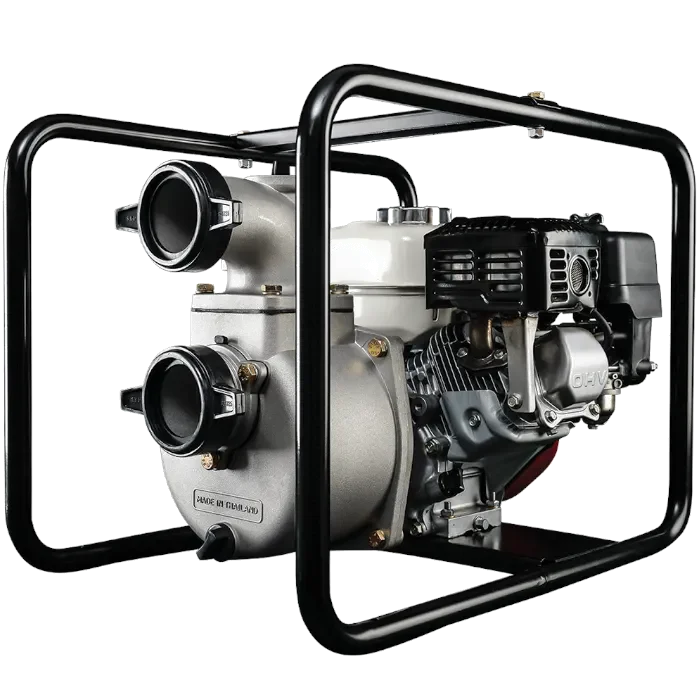

When water threatens to overwhelm, you need more than just tools; you also need confidence. The Floodfighter engine water pump by Davey is a self-priming portable unit suitable for emergencies and daily use. Its heavy-duty centrifugal design, cast iron impeller, and marine-grade aluminium casing provide tough strength without adding complexity. Whether draining flood water, operating a farm irrigation system, or emptying a tank on a tractor site, the Floodfighter® is designed for purposeful water transfer with excellent flexibility.

Its adaptability makes it ideal for flood recovery, septic tank pumping, irrigation, and large-scale dewatering operations. With a Honda GX200 petrol engine, the Floodfighter® provides consistent hydraulic performance at up to 1000 litres per minute. This combination of rugged engineering design and user-friendly operation assures that the pump is more than simply a piece of equipment, but a dependable companion for professionals in agriculture, construction, and emergency services.

Pump variation: flexible models suit different needs

Pumping requirements differ widely. That is why the Floodfighter® is available in two practical variations:

| Model No. | Inlet/ Outlet | Fuel Type | Engine Capacity (cc) | Engine |

| G8016 | 3” BSP | Petrol | 196 | Honda GX200 & Frame |

| G8016E | 3” BSP | Petrol | 196 | Honda GX200 Electric Start & Frame |

Both options are placed on a powder-coated steel roll frame with anti-vibration fittings to ensure endurance in harsh conditions. The electric start is suitable for rapid deployment, but the recoil start type offers a simple mechanical option that does not require external power.

The Floodfighter® truly is about performance flexibility. With a maximum head of 32m and a suction lift of 7 m, the device is well-suited for lengthy suction runs in flooded regions or agricultural irrigation systems. Whether you need transport for high-flow flood water or to ensure consistent water transfer in agriculture, there is a model to suit your needs.

This clarity simplifies the process: choose your favourite start technique, and you will be outfitted with a fuel-efficient pump that combines power, portability, and endurance.

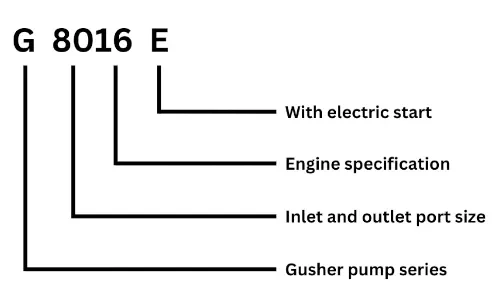

Model identification for Floodfighter pump

The Floodfighter® naming system is simple yet effective for installers, consultants, and service specialists.

Understanding the code ensures that the appropriate pump is chosen, maintained, or re-ordered without misunderstanding.

- “G” refers to the gusher pump series, which is noted for its centrifugal hydraulic performance and high flow transfer.

- The number “80” signifies the 3-inch (80mm) inlet and output port size, critical for high-capacity water circulation.

- The following digit of “16” refers to the engine frame and specification, corresponding to the Honda GX200 petrol engine.

- The suffix “E” signifies electric start versions, whereas the absence of “E” indicates a recoil start design.

For example, G8016E indicates a Floodfighter® centrifugal pump with 3-inch connections, driven by a Honda GX200, and equipped with electric start and recoil backup. This methodical approach saves time regardless of ordering, maintaining, or integrating into bigger fuel transfer pump systems on farms, building sites, or firefighting facilities.

Practical accessories: suction strainer, hoses, and fittings for complete versatility

To increase adaptability, the Floodfighter® may be combined with useful additional features.

A suction strainer keeps large debris from entering the pump, saving the impeller and mechanical seals from harm. Additional hoses expand the pump’s reach, allowing it to draw in or release water from greater distances, ideal for irrigated fields or flooded basements.

Quality fittings provide airtight connections, essential for maintaining strong priming and avoiding performance loss. These attachments make the Floodfighter® a completely customisable system capable of a wide range of applications. By adding the proper accessories, customers may improve efficiency, decrease downtime, and prolong the pump’s service life in harsh settings.

Portable protection roll frame for easy handling and stability

Every Floodfighter® comes with a powder-coated steel roll frame that includes anti-vibration mounts. This rigid structure protects the pump from impact damage and makes it simple to move over rough terrain. Operators may confidently lift, load, and secure the pump, knowing that no key components will be damaged.

During emergency flood operations, the frame’s stability maintains the unit stable during high-flow pumping. It absorbs vibration, reducing wear on farms and construction sites. The Floodfighter’s compact yet sturdy roll frame transforms it into a portable and dependable instrument for routine and emergency water operations.

Honda GX200 petrol power for reliable engine performance

The Floodfighter® is powered by the Honda GX200 petrol engine, well-known for its dependability throughout sectors. Its cast iron cylinder sleeve can resist severe use, and a dual-stage air filter assures clean combustion in dusty conditions.

The low oil protection mechanism protects the engine from internal harm by immediately shutting it down if lubrication fails. With a fuel consumption of just 1.7 litres per hour at full load, it balances power and economy, making it excellent for irrigation, dewatering, and flood relief. Smooth starting, constant torque, and global compliance with EPA and CARB standards ensure confidence in every deployment.

Honda GX200 petrol power for reliable engine performance

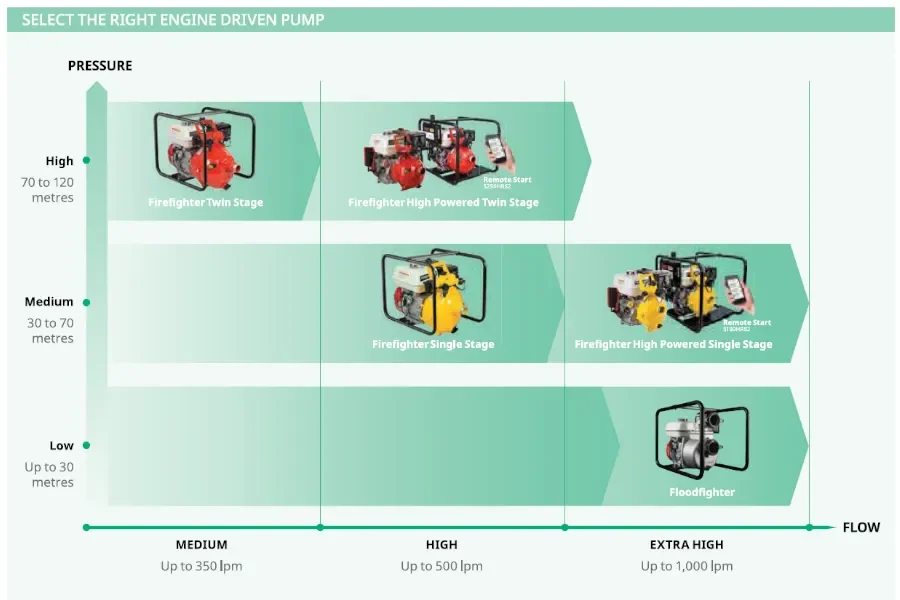

An infographic has been produced that details the specifics of Davey’s engine-driven pumps. In this particular case, the mapping of pressure at a distance in meters against Litres per minute (LPM) can be seen, portraying the adverse range of scenarios found in real-world conditions in which first responders and emergency rescuers may act accordingly with this pump information.

Like every other niche and industrial product engineering, the grouped models of engine water pump category is designed to cater to a certain allocation of needs. In the particular event as found between 70 to 120 metres, it’s in recommendation to be getting all variants of Davey’s Twin Stage Firefighter engine water pump, powering a gush-down of 350 LPM in volumetric flow rate at a low-to-moderate range of the Two Stage Firefighter, and with to a capped of 500 LPM with Davey’s higher end models of the Twin Stage engine water pump.

Under occasions of firefighting setting that combats a disaster at 30 to 70 meters, the single stage Firefighter diesel pump (or petrol, at your choice) is capable enough of doing wonders by flooding as much as 500 LPM, and to a maximum output of up to 1,000 litres per minute if it’s a highly-powered single phase Firefighter. This is considered to be Davey’s mid-range choice when it comes to selecting our forms of engine water pumps.

And lastly, for the closest parameter of up to 30 metres in distance, Davey’s sole grouped product of Floodfighter is recommended that can spurt up to 1,000 LPM.

Marine-grade aluminium case for a strong and corrosion-resistant pump body

The Floodfighter’s marine-grade aluminium housing is designed for durability. It resists corrosion and increases operating life even when exposed to harsh water conditions such as floodwater or farm runoff. Its lightweight design makes the pump portable without sacrificing strength, making operating around farms, building sites, and disaster zones easier. The aluminium casing provides mechanical protection and efficient heat dissipation by firmly encapsulating the cast iron impeller and diffuser. This clever blend of durability and portability enables the Floodfighter® to perform dependably in environments where toughness and mobility are equally important, delivering a trustworthy solution for complex pumping duties.

Open impeller is built for harsh water conditions

The Floodfighter® has a cast-iron open impeller that can handle water with grit, debris, or suspended materials. Its open structure reduces clogging while providing powerful centrifugal flow, making it ideal for septic tank pump-outs and flood drainage. Cast iron structure offers superior wear resistance, increasing service life in harsh environments.

This design makes maintenance easier, as obstructions can be cleaned rapidly without disassembling complicated internals. The impeller provides the pump’s maximum performance and dependability by combining high-volume output with strong construction quality. It is a proven design for individuals who want robustness and reliability in their equipment.

Mechanical shaft seal protection that extends service life

Protecting the heart of the pump is a carbon-ceramic mechanical shaft seal, engineered for endurance under continuous operation.

This seal prevents leaks along the engine shaft while protecting sensitive components from polluted water and abrasive particles. Its design reduces friction and wear, assuring long-term efficiency.

It reduces the possibility of internal water penetration, lowers maintenance costs, and increases pump and engine life. This dependability is critical for professional users who rely on their equipment during crises, irrigation cycles, or dewatering operations, where downtime is not an option and operational security is essential.

Included In The Box

Floodfighter Engine Water Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us