Davey Malaysia / Home / Water Pump / Davey General Purpose Dewatering Pump

Davey's General Purpose Dewatering pump

Key features:

- Sump pump type.

- Suitable for industrial sites.

- For commercial water transfer use.

- 12 months warranty for pump, motor & float switch.

- Hermetic seal for watertight closure.

Overview of Davey's General Purpose Dewatering pump

When managing water in demanding environments, efficiency and reliability are not optional but absolutely essential. Whether on a construction site, in a flooded basement, or during wastewater treatment, effective dewatering ensures that operations continue smoothly and safely. The General Purpose Dewatering pump by Davey embodies this principle. Designed to deliver dependable performance in both commercial and industrial environments, it represents the culmination of Davey’s engineering expertise in centrifugal water movement, filtration, and separation technology.

Engineered for versatility, the Davey general purpose dewatering pump range can move substantial volumes of water from flooded areas, tanks, and pits with remarkable efficiency. From everyday water transfer to complex dewatering techniques such as reducing the water table around construction sites, riverbeds, mine shafts, or caissons, these pumps operate as the quiet, unseen workforce that keeps environments stable and safe. By lowering pore pressure and maintaining an optimal hydraulic gradient, they help control drawdown and maintain system integrity, which are critical factors in geotechnical engineering and deep well management.

General Purpose Dewatering pump models

Every installation presents unique demands, from compact domestic drainage to large-scale industrial dewatering. That is why the Davey general purpose dewatering pump range offers models in both small and large configurations, each built to suit a wide spectrum of applications.

| Model No. | Motor Output, kW | Voltage, V | Outlet | Product Group |

| D15A | 0.15 | 220/240 | 1¼′′ | 1051 |

| D25A | 0.25 | 220/240 | 1½′′ | |

| D40M | 0.40 | 220/240 | 2′′ | |

| D40A | 0.40 | 220/240 | 2′′ | |

| D75M | 0.75 | 220/240 | 2′′ | 2010 |

| D75A | 0.75 | 220/240 | 2′′ | |

| D150 | 1.50 | 220/240 | 3′′ | |

| DT08 | 0.75 | 415 | 2′′ | |

| DT15 | 1.50 | 415 | 3′′ | |

| DT22 | 2.20 | 415 | 3′′ | |

| DT37 | 3.70 | 415 | 4′′ | |

| DT55 | 5.50 | 415 | 4′′ | |

| DT75 | 7.50 | 415 | 6′′ | |

| 316SS Models | ||||

| DT15/SS | 1.50 | 415 | 3′′ | 2010 |

| DT22/SS | 2.20 | 415 | 3′′ | |

| DT37/SS | 3.70 | 415 | 4′′ | |

Together, the drainage and dewatering series form a comprehensive portfolio that addresses every scale of operation, reflecting Davey’s commitment to adaptable engineering and performance you can depend on.

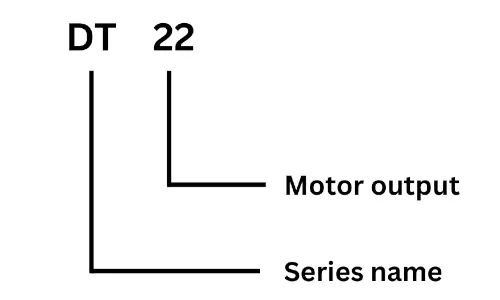

Sump pump product identification method

Selecting the appropriate model is straightforward thanks to Davey’s structured identification system.

Each model number offers clear insights into the pump’s configuration, flow capability, and electrical specification.

- Prefix “D” or “DT” indicates the series and application. The prefix “D” identifies single-phase drainage and light dewatering pumps, while the “DT” designates industrial three-phase dewatering pumps.

- The numerical values signify the relative motor output.

- The suffix letters represent operating mode, where “A” stands for automatic, fitted with a built-in float switch for automatic water level control, while “M” stands for manual, which requires external switching and is suited for controlled operation where variable water levels are expected.

Take the DT22 model as an example. The prefix “DT” identifies it as part of Davey’s heavy-duty dewatering pump series, purpose-built for industrial and construction dewatering where continuous operation and high flow rates are required. The numerical value “22” indicates that the pump is equipped with a 2.20 kW motor, delivering powerful water movement for demanding applications such as sludge dewatering, mine shaft drainage, or wastewater disposal.

Attachments

H07RN-F oil-resistant power lead

All models feature 10-metre H07RNF oil-resistant cables, specifically chosen for their flexibility and endurance in wet and contaminated environments.

These cables maintain insulation integrity even when exposed to oils, sludge, or filtration residues, ensuring continuous power delivery and electrical safety, reflecting Davey’s commitment to dependable performance.

Sand slinger lip seal

Positioned above the impeller, the sand slinger acts as a secondary barrier, preventing fine particles and slurry from entering the sealing chamber and protecting key internal components.

This reduces maintenance needs and prolongs motor bearing life, even in harsh riverbed or mine shaft dewatering environments.

Automatic float switch

The FS750-10 submersible float switch, designed to integrate seamlessly with Davey dewatering and drainage pumps, automates pump operation.

Using a captive steel ball and micro-switch mechanism, it provides precise level control, switching the pump on or off as water levels rise or fall. The hermetically sealed double-chamber design ensures reliability even in chlorinated or raw water, while its H07RNF rubberised lead resists deterioration in demanding conditions.

Available with 10 metres of waterproof lead, the FS750-10 allows flexible installation for both filling and emptying applications, offering protection against loss of prime and ensuring safe and unattended operation, a valuable feature for vacuum dewatering or deep well systems.

Low-velocity suction strainer

Each pump incorporates a low-velocity inlet strainer, which allows handling of soft solids while preventing large debris from damaging the impeller.

This ensures smooth operation during sludge dewatering processes, improving the pump longevity and minimising the risk of cavitation during construction dewatering or aquifer testing.

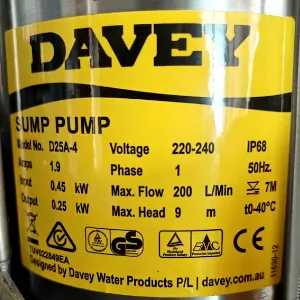

Certified safety and trusted performance

Every Davey general purpose dewatering pump is designed and manufactured to meet stringent international quality and safety benchmarks, ensuring lasting reliability in the field. Each model carries the following certifications and inspections:

European Conformity, CE: Demonstrates compliance with the European Union’s safety, health, and environmental protection standards. It confirms that every pump has been rigorously assessed for safe electrical operation, mechanical integrity, and environmental compatibility.

Geprüfte Sicherheit, GS (TÜV022849EA): Verifies that Davey’s dewatering pumps have undergone comprehensive third-party evaluation for mechanical and electrical safety. It confirms that TÜV has independently tested the product to meet German Product Safety Law.

EMS Production Inspection by TÜV: Helps to verify that the production process complies with ISO 14001 environmental standards and that every pump is produced under consistent, controlled, and sustainable conditions.

AS/NZS 60335: Ensures that each pump is designed and constructed to prevent electrical hazards, withstand demanding environmental conditions, and provide safe and long-term service in domestic and industrial installations.

Power built from a robust motor design

Sump pump selection guide

Choosing the right pump begins with knowing the type of fluid being moved. Each Davey pump is engineered to perform efficiently with specific water conditions, from clean rainwater and surface runoff to greywater, wastewater, or heavy sludge. Use this guide to match your application with the right model, ensuring reliable performance, long service life, and efficient operation across all drainage, dewatering, and wastewater handling needs.

| Suitable Fluid | Rainwater | Drainage | Dirty Water / Greywater | Wastewater / Effluent / Sewage | Sludge / Slurries | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pumps | D23A/B, D42A/B & D53A/B | Small Double Case Submersible Water Pump Models (DC10) | Small Dewatering Pump Models (D10 & D15) | Double Case Models (DCS40 & Above) | Dewatering Pump Models (D25 & Larger) | Single Channel Models (S) | Vortex Models (V) | Cutter Models (K) | Grinder Models (G) | Sludge & Slurry Models (KZN) |

| Fluids / Application | ||||||||||

| Fountains | X | ✔ | — | |||||||

| Rainwater (e.g. tank to garden or home) | ✔ | — | ✔ | — | ||||||

| Stormwater and surface run off water | ✔ | X | ✔ | |||||||

| Greywater with nil or few soft solids (e.g. septic tank pump-outs) | ✔ | X | ✔ | |||||||

| Dirty water with less than 1% small hand solids – some wear can be expected (e.g. site dewatering, swimming pool drainage, stormwater pumping) | ✔ | X | ✔ | X | ✔ | |||||

| Water with up to 10% soft solids in suspension – max. particle size is 80% of pump outlet (e.g. semi screened raw sewage, stock effluent, grease traps) | X | ✔ | ||||||||

| Water with medium volumes of hair in suspension (e.g. greywater, abattoir wash down, dog washing, animal washing) | X | ✔ | X | |||||||

| Water with stringy materials in suspension (e.g. laundromats, cotton & wool mills, food factories) | X | ✔ | X | |||||||

| Raw sewage including sanitary products | X | ✔ | X | |||||||

| Slurries with up to 35mm particles in suspension up to 70% by weight (e.g. sand and slurries, building site water, mine site water) | X | ✔ | ||||||||

Corrosion-resistant build for long-lasting strength

The 304 stainless steel motor shell, handle, and fasteners, combined with cast iron impellers and pump casings, provide excellent corrosion resistance and long-term durability.

Whether submerged in neutral pH wastewater, slightly dirty water, or temporary floodwater, the materials resist oxidation and structural degradation, ensuring long-lasting reliability and a professional finish that reflects Davey’s engineering quality.

Double mechanical seal for reliable protection

Each Davey water pump incorporates a double mechanical seal system within an oil bath, except the D15 model, which uses a single seal.

This dual-seal configuration prevents water leakage and internal corrosion, offering enhanced protection against abrasive wear from suspended solids, which is essential in geotechnical engineering and wastewater treatment operations.

Included In The Box

General Purpose Dewatering Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us