Davey Malaysia / Home / Water Pump / Davey HM Horizontal Multistage Water Pump

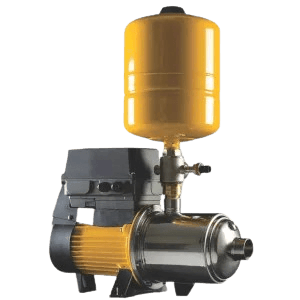

Davey's HM Series of Horizontal Multistage Water Pump

Key features:

- Standard automatic pressure system type.

- Suitable for larger households (3-7 shower heads with 5-10 pipes).

- For household, garden, farming, and agricultural use.

- 24 months warranty for pump, motor & controller.

(24 + 6 additional months with e-Warranty scheme) - Fixed pressure setting on every usage.

- Easy installation, no setting required.

All Versions of Davey's Horizontal Multistage Water Pump

Overview of Davey's HM Series of Horizontal Multistage Water Pump

In robust pressure strength exerted across multi-storey buildings and for household requiring high watering needs, the Horizontal Multistage water pump that’s introduced by Davey represents a force of action in maxed-out drive. This is accomplished primarily with a built-in line of stainless steel impellers sorted as stages to increase aquatic thrust, making sure shop lots and even larger homes of heavy needs have the necessary h2o application as intended. The Horizontal Multistage naming is the result of its structured impellers in design which made this electric pump to be perceived as vividly represented.

Davey’s Horizontal Multistage line of centrifugal pumps is also often abbreviated as the HM series internally, and one that’s regularly used across Davey’s authorised dealers and fans worldwide. Only hydraulic parts are fitted in to ensure a smooth exercise of carrying pressurised fluids, where alloy composite is deployed into its housing for its strong combat against corrosion. When you’re hard-pressed to consider the Horizontal Multistage, the rule of thumb is that Davey Water Products’ lower end models are meant for one’s own dwelling and irrigating gardens, whereas the mid to high-tier designs are perpetuately constructed for farming and commercial application.

Horizontal Multistage Water Pump Variations

| Pump Model | Product Code (SKU) |

|---|---|

| HM60 | HM60-06, HM60-06T, HM60-08, HM60-08T, HM60-10, HM60-10T |

| HM80 | HM80 only |

| HM90 | HM90-08, HM90-08T, HM90-11, HM90-11T, HM90-13, HM90-13T |

| HM150 | HM150 only |

| HM160 | HM160-15, HM160-15T, HM160-19, HM160-19T |

| HM270 | HM270-19, HM270-19P, HM270-25, HM270-25P |

| Three Phase Models Only | |

| HM150-X-3 | HM150-15-3, HM150-22-3, HM160-15-3 |

| HM160-X-3 | HM160-15-3, HM160-19-3 |

| HM270-X-3 | HM270-19-3, HM270-25-3 |

| HM300-X-3 | HM300-30-3 |

Multiple iterations of the Horizontal Multistage electropump has been featured, altogether catering for a variety of situations and means. Likewise, as it is culminated with various specifications found, this produces different performance output depending on the water pump’s selection.

The Horizontal Multistage pump can have between 3 to 6 impellers built within, which is further defined as 3, 4, 5 and/or 6 stages respectively. And as the number of staging bodies increases, so also the increment of flow rate in litre per minute (or L / min as the measurement symbol). All information for the HM h2o pump versions is written as elaboratively as possible with technical charting accuracy to be viewed and referenced for public information purposes.

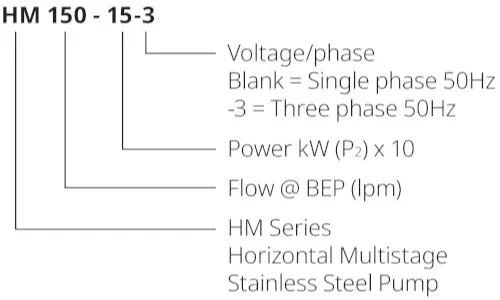

Identification of Davey's Horizontal Multistage Water Pump

All product codes’ categorisation from Davey Water Products is centralised, and this is used in uniformity worldwide. The electropump’s identification begins with:

1) A sequencing of a shortened naming.

2) Followed-up by the flow rate measurement.

3) The kilowatt or in power output.

4) Lastly, the phase of voltage found at its rear.

For the Horizontal Multistage water pump, an example found in the image is the HM150-15-3 encoding. Again, this begins with its short-form calling, or ‘HM‘ in this case, followed by 150 as its volumetric flow rate found per minute that produces 1.5 power Kilowatt that has a 3 phase of voltage connection.

Internally, this entity code mainly remains as a tracking number within Davey’s warehouse to retrieve the accurate water pump for order reasons, and that the inventories are arranged the same for professional sorting in our wide industrial range of shelves.

Attachments

Pressure Controller

The Torrium 2 can be a crucial integrating part fitted onto Davey’s HM centrifugal pump. It’s an electrotechnology designed as a smart controller to regulate even water flow and further offer steady pressure within households and commercialised offices. This is merely possible by starting the pump on a pressure drop and stopping under low flow statuses measured around 1 litre per minute (LPM).

One of the perks in getting the Torrium2 is to lessen the consequential burden of activating and deactivating the Horizontal Multiple-Stage electropump. This soft start-stop is only finalised through its innate mechanism by increasing and decreasing the speed very gradually, leading to the prevention of water hammer that can otherwise cause impending damage.

Strong Starting Pressure: A core component found is the sensor that detects an ardent water demand, intervening only when the pressure drops to 80% of the peak output. This peak is set automatically whenever the booster pump stops, making a flexible purpose that is defined by any pump’s performance.

Start Adaptability: Leakage are often a problem that causes water pump cycling, but the Torrium2 is wise enough to discern between users requiring water and unnecessary leaking (like droplets coming from the tap). In circumstances where extremely low flow rate happens, this smart controller would adjust itself to 50% of its last used pressure to further prevent additional revolution. Meanwhile, with any hydration ran above 0.5 LPM, the Torrium2 would revert its adaptable starting into normal mode to initiate the Horizontal Multistage pump.

Dry-Running Protection: Water pumps are always built to be filled with a full volume of liquid moving within. As a result, whenever the Torrium2 analyses a loss of prime within Davey’s horizontal multistage centrifugal pump, a fail-safe action becomes enclosed to completely shut the pump down from continued operation. Amid the reduction of timedown, the Torrium2 will also retry itself after 5 and 30 minutes interval, or even 1, 2, 4, 8, 16, and 32 hours. However, once an appropriate water pressure flows within, it would also restart itself to allow the Horizontal Multistage pump to run.

The representative models of Davey’s Horizontal Multistage water pump that includes the Torrium 2 holds an additional alphabetical letter of ‘T‘ in the rear end (just behind the numerical number of the Kilowatt / power2 sequencing) of its formal product code. A quintessence seen is such as the HM160-14T alternative.

Mechanical Pressure Switch

Davey’s Horizontal Multistage pump can come with the fastening of a mechanical pressure switch, and this device is installed as an oversight to enable functionality based on the desired pressure level.

Trigger / Closure: Whenever watering levels rises above or fall below the ideal pressure, this initiates Davey’s Horizontal Multistage electropump into use or discontinuation.

Adjustable: The cut-in and out points are tweakable by end consumers to match the needs of a water system, prioritising a balanced dampening application instead of stressing Davey’s Horizontal Multistage water pump. This further inhibits unnecessary pressure surge or fall that damages pipes.

Resource / Energy conservation: Natural resources such as our raw water source supplied by Air Selangor or relatable ration-sourcing entity can be conserved as much as possible using the Horizontal Multistage water pump with the pressure switch variation. This happens only because the strength of h2o flow rate is welcome only when purposefully needed, ultimately reducing wear and tear of the electropump as well as maintaining a longer lifespan.

The SKU modification of Davey’s horizontal multistage that includes this pressure switch is acknowledged with an systematic alphabet letter of ‘P’ that is placed at the back. One examplar is the HM270-19P electropump.

Pressure Tank

One last accessory that can be opted to be attached onto Davey’s Horizontal Multistage water pump is the pressure tank itself. Its duty without a doubt essential towards the continuing frequency of use for all types of booster pump, as water can be stored within to reduce the activation and deactivation arrangement seen.

Possessing a mocked diaphragm, this flexible layer is what aids to separate h2o and air within the pressure tank itself. This is of vital importance as cavitation can happen if both liquid and oxygen becomes mixed, causing imminent destruction that can be fatal towards the surroundings.

Internally, this works by having the water kept in reserve to press against the diaphragm, which in turn compresses the air atmosphere above it. Once the reservoir reaches the threshold, the Horizontal Multistage water pump will halt on its own. And only through a running pipe, shower head, or a toilet system becomes used that the constricted air flow would push the water out. Interchanging from cut-out pressure to cut-in slowly and steadily until its bare minimum pressure, Davey’s Horizontal Multistage centrifugal pump would then reset to begin its refill once again.

Acquired Water Pump Accreditations

To penetrate further into different territorial regime and continents like Malaysia of Southeast Asia, Davey have rounded up the mandated accreditations needed for a market-entry setup. As such, the Horizontal Multistage centrifugal pump has been tested and was awarded with world-class certifications found. These certs are bounded towards home appliance use, to examining whether the water pump can be safely consumed for ration purposes, and/or even observed and stringently tested within the confines of manufacturing production line to determine if the pump is created in consistent quality.

SGS Approved: The scrutiny conduct of Société Générale de Surveillance have made so that Davey’s HM water pump carries a safe yardage of electricity safety standard within residential application. Retort examples towards the definition of electrical protection includes the testing of accidental shock, potential centrifugal pump’s shorting, potential fire generation and even validating if the Horizontal Multi-stage is properly enclosed and confined.

European Standards: The official governing body in harmonising technical mandation across Europe, and this is complied by Davey for the Horizontal Multistage pump to ensure security, excellency in grading, interoperability, greener conscience and trading access towards the Western soil. Technological advancement is another one to uplift society that is favoured with this water pump itself.

International Electrotechnical Commission (IEC): Founded in 1906, the global authority in regards of voltage and electronic-based technology where benchmarks are published and adhered to has been followed by Davey for all of its mechanical engineering products, in order to realise mutual recognition arrangements (MRAs) for wider trade access.

Australian Standards: The primary advantage point of earning Davey’s home ground’s trust, wherein the recognition of the Horizontal Multistage pump and its diesel motor iteration for electric-powered safety approval is finalised and gained from an self-governing, non-profit regulation.

- AS4020:2005: The benchmark of the Australian Standard signifying that any materials used and applied in the making of water systems, which includes the Horizontal Multistage pump, must remain safe upon contact with drinking water. Various points of reference and testing methods on the pipes, attachments, coating, and any relatable materials are trialed with this electropump, and this certified byproduct is significant for manufacturers and suppliers like Davey to instigate a guarantee that liquids ran by their water pumps are inherently safe to be consumed.

New Zealander’s Standards: Another consumer safety verification of the Oceania region, in which Davey have earned for its credentials for exporting rationality.

ISO 9001: A quality management system that separates the average pump manufacturer with that of the higher tier alignment. Davey’s Horizontal Multistage electropump have successfully garnered this as officials were examining our routine in the continuous strive for improvement, while equally found was the equality of our products from one batch to another across the supply chain distribution.

ISO 14001: The practised protocol of green conscience when making the Horizontal Multistage pumps for a better world, and a preserving future. The ISO 14001 represents the ushering commitment of recycling exercises throughout Davey’s assembly, the closure of unnecessary lightings during certain inactivity periods, the replacement of older bulbs with that of light-emitting diode during the pump formation, and also the proper route divising for a faster and distant-closing delivery of Davey Malaysia’s goods.

Overall, the combination result of gathering these accreditations have emphasised moreso on Davey’s credibility and reputation enhancement, while also bringing customer satisfaction upon the repeated use of the Horizontal Multistage electropump.

Full-Powered, Consistent Speed Motor Pump

Davey’s Horizontal Multistage pump operates in complete strength, uniform water pressure speed throughout any duration of everyday consumption. This is as straightforward as any centrifugal pump gets regardless of the prevailing utility duration.

Easy Setup: Simplicity holds the truth behind this Horizontal Multistage electropump, in which it’s conveniently installed by arranging it just below the water tank, plugging in and then letting it operate. No further steps are required for household and commercial folks wanting a direct water pump setup.

More than 200 starts / hour: Part of the essential value that draws Davey’s Horizontal Multistage pump to its fable is a stable and strong number of starts the engine can attain without going into mechanical failure, and this hourly cycle far exceed many of our competitors in the centrifugal pump marketplace. However, having more than 200 starts per hour is exclusive to certain Hotizontal Multistage pump models only.

Reliable And Proven: All horizontal multistage pumps have been available for a substantially long period, which goes to show that the mechanical engineering thoughts needed to manifest this contraption is reliable and proven beyond the shadow of a doubt. Thus, the readily abundant research and development, as well as supportive culture and a wide variety of spare parts that are easily found – if there is a need to fix this centrifugal pump at all.

Cost-Savvy: With adequate parts, and an electrical motor pump featuring a singular direct-to-access force of gush required to shower well, irrigate, or clean easily, the already well-developed engine electrotechnology needs no further tuning, while Davey Malaysia has a robust supply chain to easily assemble the Horizontal Multistage water pump in bulks, totalling to a cost-savvy product that are now widely used in the world.

Fitting Horizontal Multistage Pump For The Household

A visual representation organised based on all the factors of an landed accommodation is created by Davey Malaysia’s mechanical engineers to pinpoint the accurate water pumps needed for the local shelter, as can be seen:

The HM80 and HM150 are one of Davey’s many sort of Horizontal Multistage water pumps assigned for the house usage.

As can be seen, the engineers within this niche have calculated all the necessary water system (which includes the average piping structure) variables, and finds that single to double storey housing can have the HM80 to fulfill every single drenching necessity, whereas 3 storey places would have to opt for the HM150 electropump instead. The logic can also be mentioned that the larger the place of residence is, the bigger the version of the Horizontal Multistage water pump one must fit in.

Horizontal Multistage Pump's Variance In Inlet Sizing

The main task of a suction inlet across any water pump is to allow the ideal form of fluids to come in and be passed into the system for additional pressurisation. This scenario varies depending on the centrifugal pump being deployed.

For example, in the case of a sump pump, sewage can be drawn into their water system’s engine as there lies a grinder and a filter-strainer within the inlet to remove trapped debris within, altogether aiding to alleviate floods and/or waste management for hygiene and ethical reasons. For Davey’s Horizontal Multistage pump, the main action is to draw in clean water source only, just as it is designed as a Home Pressure System.

Unidirectional Flow: The electrical motor runs to pull in water through a pressure differentiation, and with a dynamic structure to support flow rate, the Horizontal Multistage water pump helps to direct the aquatic fluids unidirectionally into the impeller section.

Different versions of this electropump features different inlet sizing. This is to ensure that the pump’s output matches the housing’s piping system as h2o becomes readily overflowing. Yet in the event if the pipe’s diameter was found to be far smaller (or bigger) than the Horizontal Multistage pump’s inlet itself, a connector can be used to bridge and correct the dimensional gap differences.

Below is a tabulated summation of all the inlet port suction found across Davey’s HM series:

| 240V Single F | ||

|---|---|---|

| Product Code | Ports | |

| Suction BSP | Discharge BSP | |

| HM60-06 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM60-08 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM60-10 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM80-08 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-08 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-11 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-13 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM150-11 | 1.5 inch (38.1mm) | 1.5 inch (38.1mm) |

| HM150-15 | 1.5 inch (38.1mm) | 1.5 inch (38.1mm) |

| HM150-22 | 1.5 inch (38.1mm) | 1.5 inch (38.1mm) |

| HM150-15-3 | 1.5 inch (38.1mm) | 1.5 inch (38.1mm) |

| HM150-22-3 | 1.5 inch (38.1mm) | 1.5 inch (38.1mm) |

| HM300-30-3 | 2 inch (50.8mm) | 2 inch (50.8mm) |

| HM160-15 | 1.5 inch (38.1mm) | 1.25 inch (31.75mm) |

| HM160-19 | 1.5 inch (38.1mm) | 1.25 inch (31.75mm) |

| HM270-19 | 2 inch (50.8mm) | 1.5 inch (38.1mm) |

| HM270-25 | 2 inch (50.8mm) | 1.5 inch (38.1mm) |

| 415V Three P | ||

|---|---|---|

| Product Code | Ports | |

| Suction BSP | Discharge BSP | |

| HM60-06-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM60-08-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM60-10-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-08-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-11-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM90-13-3 | 1.25 inch (31.75mm) | 1 inch (25.4mm) |

| HM160-15-3 | 1.5 inch (38.1mm) | 1.25 inch (31.75mm) |

| HM160-19-3 | 1.5 inch (38.1mm) | 1.25 inch (31.75mm) |

| HM270-19-3 | 2 inch (50.8mm) | 1.5 inch (38.1mm) |

| HM270-25-3 | 2 inch (50.8mm) | 1.5 inch (38.1mm) |

As any of Davey’s Horizontal Multistage water pump achieves its full water suction, and there being, the absence of air pockets within the water system, this phenomena realises on its own as a required net positive suction head (NPSH).

Lesser Friction: Larger inlet diameters of this centrifugal pump equates to having better flow rate, and is the effect of lesser resistance as aquatic flow within far easily. This is also another occurence where self-priming becomes much faster.

Corrosion-Resistant Alloy For Pump's Volute

The volute, in a seemingly cylindrical appearance keeping multiple staging bodies (diffuser and also impellers) in tact, is actually spiral-in-shape internally that is built under a polished and rugged composite metal combination. The implemention behind this for the Horizontal Multistage water pump holds four reasons:

Assist the rampant strength of discharging fluids as water swirls and move through each phase of the impeller, before leaving through the outlet consistently. The carefully crafted volute of the electropump is well-thought out to lessen turbulence, altogether maximising flow rate.

Protective barrier: Otherworldly volute casing durability prevents external residue (or even litter) from potentially coming in that may hinder the clean water supply sent by the Horizontal Multistage pump, and that it can otherwise cause further damage to the existing arrangement.

Interchanging Energy States: From the initial episode of having the motor develop a suction force, and towards the interior vicinity where fastened impellers impart its kinetic energy, the water is then steadily pushed away from the center and resisted to the outer alloy walls centrifugally before it becomes discharged onto the outlet of the Horizontal Multistage pump. Throughout this sequence, this change of energy converts from kinetic to pressure as the volute chamber becomes filled, which thus reduces the speed while concurrently raising the water pressure. This phenomena adheres to the observation and scientific law of Bernoulli’s principle.

Self-Priming Affirmation: As the volute body becomes moistened and hydrated internally as a whole, this would eventually devoid the Horizon Multistage water pump of any air gap that enables self-priming. If not, trapped air that surged itself into the impeller as it spins alongside water may result in destructive cavitation.

Impellers & Diffusers In The Horizontal Multistage Pump

Within the volute chambers found are compartmentalisation of impellers and diffusers, arranged orderly in the form of staging bodies from one to another. Also known as the protection bracket, these staging bodies holds a significant role of pivoting these mechanisms in place, ensuring that it doesn’t become loose within the Horizontal Multistage water pump as operation and revolutions begin.

As water flows from the first phase to another, each staging body room would drive a hike in pressure needed for optimal running faucet use, showering, or applying across other daily essentials.

Closed Impeller Design With The Horizontal Multistage

Closed impellers are attached and installed onto the shaft for improved fluid handling amid the driving of its rotor, and this is utilise to lessen the thrust load.

Better Performance: As it is double-walled (both front and back) constructed from its vane, liquids within are directed appropriately to a smooth and reliable output as they exit in centrifugal force to the outlet, making an outstanding hydraulic performance of an electropump.

Cavitation-Apparatus Prevention: The Horizontal Multistage water pump is far less prone to the creation and collapse of air bubbles within the water because of the impellor’s protective barriers, and this results in mitigating further damage on the pump.

Longer Service Life: As thrust load becomes minimised, the bearing life, frequency of use and shafting costs becomes cut down, equating for the Horizontal Multistage centrifugal pump to be long-lasting.

Stainless steel material is used to bypass the deterioration as the impeller and diffuser becomes dampened with full volumes of fluids at all times, while maintaining powerful endurance throughout the cycles of the Horizontal Multistage water pump use.

Smooth Surface: Before inserting the impeller onto the electropump, this part is polished smoothly as it can be to reduce further surface tension, totaling for the least friction amounted and the most minimal of turbulence generated. The aftermath of this practice within Davey’s Horizontal Multistage pump draws about greater efficiency of fluid movement, and all the while decreasing unnecessary energy loss by power consumption (in kilowatt).

Thermodynamics Stability: In cases where the source of gush supplied vary in temperature, the impeller in better graded stainless steel material remains stable in terms of performance, where its mechanical properties hardly contracts nor expand, putting a versatile use of sucking hot and cold clean water into the Horizontal Multistage pump.

Generator Protection With Backplate And Mechanical Seal

The section where electrical engineering breaches its mechanical field implementation is the most crucial aspect to determine if Davey’s Horizontal Multistage pump would continue to work or not. As the engine’s electrotechnology components must remain away from water contact to prevent short-circuiting, a backplate and a mechanical seal part is integrated within to prevent any potential splash from entering the core motor. This is with a gasket or a washer that is used to seal the remaining gaps found.

Within the same incident, water spiraled outwardly would be routed in distribution towards the discharge outlet, achieving the intended water supply as needed with the centrifugal pump. The backplate and mechanical seal is also put in place as a means to support the shaft in stationary position, because once rotation begins upon use, these instrumental parts aid Davey’s Horizontal Multistage pump from tilting or going out of whack.

A circlip can be discovered before the backplate and inside the mechanical seal, where rotating stress is transferred onto it to ensure that the Horizontal Multistage water pump’s mechanical seal is constantly enclosed. However, for HM80 and HM150 series only, this circlip (also known as clip spring in Davey Water Products’ official manual) is completely absent.

O-Ring Tighteneed, With Vibration-Absorbent Spacers

- With every core piece joining from one segment to another internally, the Horizontal Multistage electropump is attached with an O-ring whenever possible to ensure a tight fitting and to prevent additional latent leakage from appearing out. Moulded with EPDM (ethylene propylene diene monomer) rubber, this hydrocarbon succeeds neoprene when it comes to higher warmth, and one that is perfect as it meshes well with Davey’s Horizontal Multistage water pump for temperature sturdiness. Typically, many of these O-rings can be found within the volute casing.

- Spacers are set in to offer adequate spacing among the rotating bits, in what otherwise could grind each other within this Horizontal Multistage water pump. This positioning is also important to aid the mechanical bearings to remain in exact position, while stopping any of the individual parts from being overly compressed as the HM electropump initiates their operation.

- Absorbing Vibrations: To temper further rigidity, these spacers within the Horizontal Multistage centrifugal pump acts as pseudo-vibration absorbents to weaken any unnecessary machine stress.

Likewise, adhering to even out toughness among the components, every single parts found internally in this water pump — the impellers, mechanical seal, spacers, the circlip, and even its volute casing are all made in the robust quality of stainless steel 304 (or SUS304). Only the shaft connected from the motor is missioned to transmit rotating power critically, and is made with the enduring SUS316.

Operating Limits of Horizontal Multistage Pumps With Torrium2

| Operating Limits | |

| Maximum continuous flow rate | 200L / min (53 US gallons) |

| Maximum operating pressure | 700 kPa* (102 psi) |

| Maximum current | 10 amp |

| Cut-in pressure range | 80% of pump shut-off head |

| Maximum water temperature | 65°C (149°F) |

*Dependent on optional tank pressure rating, operating pressure to to 820 kPa may be achieved.

*The ‘L’ symbol is synonymous with litre.

*kPa is a derived unit of pressure.

*Psi is also defined as pounds per square inch.

*Amp is the shortened naming of Ampere, otherwise known as ‘A’ also.

*Degree celsius is marked as °C, whereas °F is the United States variant of Degrees Fehrenheit.

Hydraulic Performance of Davey's HM60 Horizontal Multistage Pump With Torrium2

| Single Phase Models | HM60 |

Motor: P1 kW P2 kW | HM60-06T – P1 kW: 0.85 HM60-06T – P2 kW: 0.58 HM60-08T – P1 kW: 1 HM60-08T – P2 kW: 0.72 HM60-10T – P1 kW: 1.25 HM60-10T – P2 kW: 0.94 |

Amps: Run Start | HM60-06T – Run: 4 HM60-06T – Start: 18 HM60-08T – Run: 4.5 HM60-08T – Start: 18 HM60-10T – Run: 5.9 HM60-10T – Start: 28 |

Ports (BSP): Suction Discharge | All – Suction: 1.25 F All Discharge – 1 M |

| Nominal operating pressure (kPa) | HM60-06T: 280 HM60-08T: 360 HM60-10T: 430 |

| Maximum pump pressure (kPa) | HM60-06T: 460 HM60-08T: 575 HM60-10T: 690 |

| Tank air pre-charge (kPa) | HM60-06T: 320 HM60-08T: 400 HM60-10T: 480 |

| Nominal flow (L / min) | All in 60 L / min (16 US gallons) |

*The measuring symbol ‘kW’ is known as kilowatt.

*BSP on the ports row represents British Standard Pipe.

*The suction port in F and M represents Female and Male respectively.

Hydraulic Performance of Davey's HM90 Horizontal Multistage Pump With Torrium2

| Single Phase Models | HM90 |

Motor: P1 kW P2 kW | HM90-08T – P1 kW: 1.1 HM90-08T – P2 kW: 0.78 HM90-11T – P1 kW: 1.4 HM90-11T – P2 kW: 1.05 HM90-13T – P1 kW: 1.7 HM90-13T – P2 kW: 1.4 |

Amps: Run Start | HM90-08T – Run: 4.9 HM90-08T – Start: 20 HM90-11T – Run: 6.5 HM90-11T – Start: 28 HM90-13T – Run: 7.2 HM90-13T – Start: 40 |

Ports (BSP): Suction Discharge | All – Suction: 1.25 F All Discharge – 1 M |

| Nominal operating pressure (kPa) | HM90-08T: 310 HM90-11T: 420 HM90-13T: 480 |

| Maximum pump pressure (kPa) | HM90-08T: 460 HM90-11T: 585 HM90-13T: 680 |

| Tank air pre-charge (kPa) | HM90-08T: 320 HM90-11T: 410 HM90-13T: 475 |

| Nominal flow (L / min) | All in 90 L / min (24 US gallons) |

Hydraulic Performance of Davey's HM160 Horizontal Multistage Pump With Torrium2

| Single Phase Models | HM160 |

Motor: P1 kW P2 kW | HM160-15T – P1 kW: 1.9 HM160-15T – P2 kW: 1.5 HM160-19T – P1 kW: 2.3 HM160-19T – P2 kW: 1.8 |

Amps: Run Start | HM160-15T – Run: 8 HM160-15T – Start: 40 HM160-19T – Run: 9.7 HM160-19T – Start: 40 |

Ports (BSP): Suction Discharge | All – Suction: 1.5 F All Discharge – 1 M |

| Nominal operating pressure (kPa) | HM160-15T: 340 HM160-19T: 400 |

| Maximum pump pressure (kPa) | HM160-15T: 460 HM160-19T: 600 |

| Tank air pre-charge (kPa) | HM160-15T: 320 HM160-19T: 420 |

| Nominal flow (L / min) | All in 160 L / min (42 US gallons) |

Operating Limits of Davey's Horizontal Multistage Pump With Torrium2

| Operating Limits | |

| Maximum continuous flow rate | 200L / min (53 gallons / min) |

| Maximum operating pressure | 700 kPa* (102 psi) |

| Maximum current | 10 amp |

| Cut-in pressure | 80% of pump shut-off head |

| Maximum water temperature | 65°C (149°F) |

*Dependent on optional tank pressure rating, operating pressure to 820kPa may be achieved.

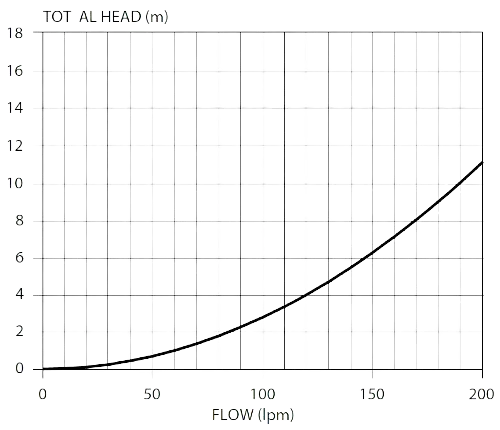

Hydraulic Loss of HM Pump With Torrium2

Hydraulic Performance of Davey's HM270 Horizontal Multistage Pump With Pressure Switch

| Single Phase Models | HM270 |

Motor: P1 kW P2 kW | HM270-19P – P1 kW: 2.4 HM270-19P – P2 kW: 1.9 HM270-25P – P1 kW: 3.2 HM270-25P – P2 kW: 2.5 |

Amps: Run Start | HM270-19P – Run: 10 HM270-19P – Start: 40 HM270-25P – Run: 13.8 HM270-25P – Start: 66 |

Ports (BSP): Suction Discharge | All – Suction: 2 F All Discharge – 1.5 F |

| Nominal operating pressure (kPa) | HM270-19P: 200 HM270-25P: 250 |

| Maximum pump pressure (kPa) | HM270-19P: 300 HM270-25P: 400 |

| Tank air pre-charge (kPa) | HM270-19P: 180 HM270-25P: 230 |

| Nominal flow (L / min) | All in 270 L / min (71 US gallons) |

Operating Limits of the Horizontal Multistage Water Pump With Pressure Switch

| Operating Limits | |

| Maximum continuous flow rate | 430L / min (114 US gallons / min) |

| Maximum operating pressure | 1000 kPa* (145 psi) |

| Maximum inlet pressure | 600 kPa (87 psi) |

| Maximum water temperature | 95°C (203°F) |

*Dependent on optional tank pressure rating, operating pressure to 820kPa may be achieved.

Horizontal Multistage Pump's Electrical Data

| Pump | |

| Speed | 2900 rpm |

Supply voltage

| 230±10% |

| Supply frequency | 50 Hz |

Enclosure class

| IP55 |

| Insulation class | Class F |

| Torrium2 | |

Voltage | 220V-240V ± 10% |

Phase | Single |

Hz | 50 / 60 |

IP rating | IP56 |

Maximum load current | 10A |

Maximum motor size @ 240V input | 1.8 kW |

Surge protection | Varistor |

*RPM is the abbreviation of revolution per minute.

*Hz is also known as Hertz.

*Current in ‘A’ represents ampere.

*kW is the short-form of kilowatt.

Materials of Construction For The Horizontal Multistage Centrifugal Pump

| Materials of construction | |

| Part | Material |

Casing | 304 stainless steel |

| Impellers | 304 stainless steel |

Stages (casing) | 304 stainless steel |

| Pump shaft | 316L stainless steel |

| Stage centring device | 304 stainless steel |

Mechanical seal:

|

Carbon |

| O-ring | EPDM |

| Plug | 316L stainless steel |

| Motor shell & lantern bracket | Aluminium with baked polyester powder coat finish |

| Motor feet | Xenoy |

| Fan cowl / rear foot (models up to 1.05kW) | Polypropylene |

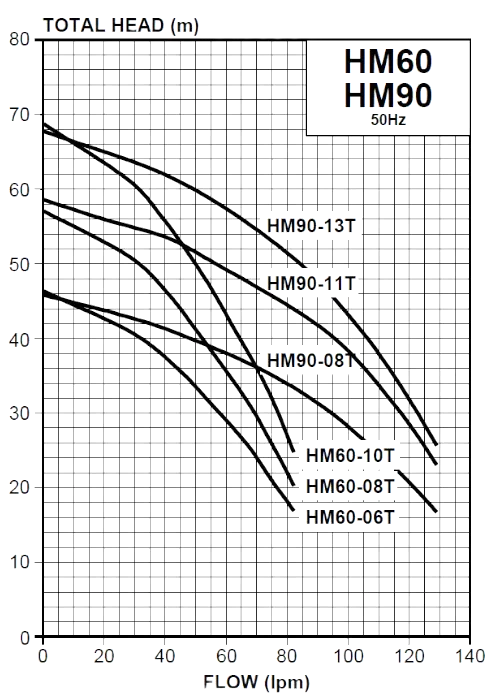

Horizontal Multistage Pump's Q-H Curve For HM60 & HM90

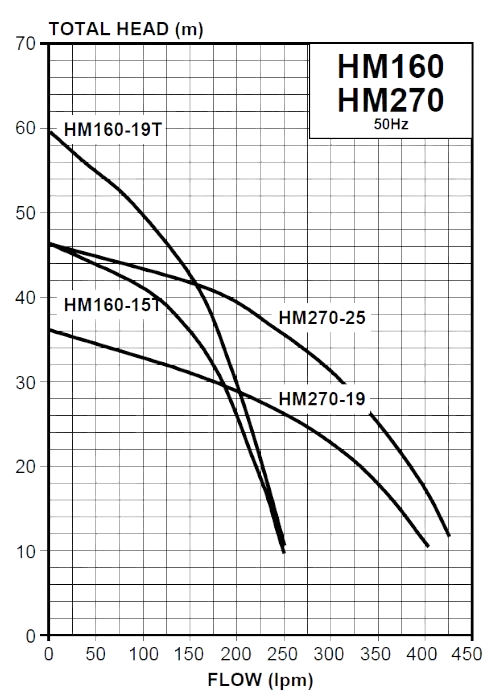

Horizontal Multistage Pump's Q-H Curve For HM160 & HM270

Included In The Box

Horizontal Multistage Water Pump

User Manual

Proof of Purchase

24 Months of Manufacturer Warranty (Increased by Another 6 Months with e-Warranty Scheme)

Downloads

All Household Water Pumps In Grouped Product View

Contact Us