Davey Malaysia / Home / Water Pump / Davey Single Channel impeller Submersible Water Pump

Davey's Single Channel Impeller submersible pump

Key features:

- Sump pump type.

- Suitable for industrial use.

- For sump emptying, septic effluent disposal, water transfer, pumping light slurries and factory waste removal.

- 12 months warranty for pump, motor & float switch.

- Hermetic seal for watertight closure.

Overview of Single Channel Impeller submersible pump

When water becomes more than just a resource, when it turns into a challenge, reliability becomes everything. Whether you are managing wastewater in a residential complex, moving stormwater in a construction zone, or transferring effluent from an industrial site, the single channel impeller submersible pump series by Davey is built to make water work smarter.

Engineered with precision and backed by decades of hydraulic expertise, this centrifugal pump series combines robust engineering with everyday practicality. Designed for high-volume liquid movement, these submersible sewage pumps thrive in demanding drainage and wastewater applications, where performance, reliability, and safety cannot be compromised.

With motor outputs ranging from 0.75 kW to 7.5 kW, the single channel impeller design ensures fast, efficient flow with minimal risk of clogging. Each model is built for continuous duty in wastewater, light slurry, or greywater applications, offering smooth operation even when solids are present. Whether installed free-standing or on slide rails, every pump in this range reflects Davey’s long-standing commitment to quality, environmental care, and dependable service.

Tailored solutions for every application

Every installation has its own demands. The Davey single channel impeller submersible pump range offers multiple models in both single phase (220-240 V) and three phase (380-415 V) configurations to suit domestic, commercial, or industrial environments.

From compact residential sump applications to large-scale wastewater transfer, there is a solution for every setting. The table below summarises key specifications to help you choose the ideal model for your installation.

| Model No. | Motor Output, kW | Rail Kit | Voltage | Outlet |

| D75SA | 0.75 | SR50 | 220/240 | 2′′ |

| D150S | 1.50 | SR80 | 220/240 | 3′′ |

| D150SA | 1.50 | SR80 | 220/240 | 3′′ |

| DT08A | 0.75 | SR50 | 415 | 2′′ |

| DT15S | 1.50 | SR80 | 415 | 3′′ |

| DT22S | 2.20 | SR80 | 415 | 3′′ |

| DT37S | 3.70 | SR80 | 415 | 4′′ |

| DT55S | 5.50 | SR100 | 415 | 4′′ |

| DT75S | 7.50 | SR100 | 415 | 4′′ |

*415 V models are suitable for commercial applications only.

*316 Stainless Steel Models:

| Model No. | Motor Output, kW | Rail Kit | Voltage | Outlet |

| DT08S/SS | 0.75 | SR50SS | 415 | 2′′ |

| DT15S/SS | 1.50 | SR80SS | 415 | 3′′ |

| DT22S/SS | 2.20 | SR80SS | 415 | 3′′ |

| DT37S/SS | 3.70 | SR80SS | 415 | 4′′ |

| DT55S/SS* | 5.50 | SR100SS | 415 | 4′′ |

| DT75S/SS* | 7.50 | SR100SS | 415 | 4′′ |

*Models listed with ‘ * ‘ may not be stocked. Delivery times can be confirmed at time of order.

Each model delivers flow rates up to 2150 litres/minute and head performance of up to 32 metres while managing soft solids up to 80% of the discharge size. With their open impeller design, these submersible sewage pumps are less prone to clogging, making them ideal for installations requiring rapid liquid removal and consistent hydraulic performance.

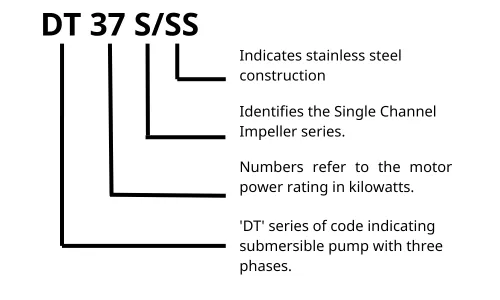

Smart model identification

Selecting the right pump is simpler when you understand the model code.

Each Davey submersible sewage pump carries a structured naming convention that reveals its design and performance characteristics at a glance:

- Prefix “D” or “DT”- Indicates the submersible centrifugal pump type. “D” represents single phase, while “DT” designates three phase models.

- Numbers following the prefix – Refer to the motor power rating in kilowatts.

- Suffix “S”- Identifies the single channel impeller sewage series, specifically engineered for pumping wastewater and light sludge.

- Suffix “A”- Denotes automatic operation, fitted with a float switch for automatic start/stop based on liquid level.

- Suffix “SS”- Indicates 316 stainless steel construction, offering superior corrosion resistance for aggressive environments or coastal applications.

For instance, DT37S/SS represents a three-phase 3.7 kW single channel impeller submersible sewage pump constructed from 316 stainless steel, suitable for continuous-duty operation in commercial drainage systems or effluent transfer stations.

Attachments

Oil-resistant HO7RN-F power cable

Electrical safety and reliability are vital for any submersible pump, and Davey addresses both with its heavy-duty HO7RN-F oil-resistant power cable. Supplied with a 10-metre HO7RN-F oil-resistant lead, it is engineered for safe operation in damp, oily, and chemically exposed environments.

Its rubber insulation withstands mechanical stress, moisture ingress, and temperature fluctuations, ensuring consistent electrical performance during continuous operation.

The cable’s high-grade sheathing resists cracking, swelling, or degradation over time, protecting internal conductors from electrical faults or voltage drops.

Slide rail kit for effortless installation

Maintenance access is simplified with Davey’s purpose-designed slide rail kits, available in multiple sizes to match the S Series pump range.

These kits allow the submersible sewage pump to be installed or removed from deep pits without the need to disconnect pipework or enter confined spaces, saving time and improving safety. Once mounted, the pump automatically aligns with the discharge connection as it slides into position, forming a secure and watertight seal.

During servicing, it can be easily lifted along the guide rails for inspection or cleaning. Constructed from corrosion-resistant materials, the SR50 to SR100 kits are ideal for long-term use in sewage or drainage environments, offering long-term reliability, convenience, and efficient pump management.

Certifications of submersible pump

Each Davey single channel impeller submersible pump is the result of precision engineering and rigorous quality control. Designed for continuous operation in wastewater, effluent, and sewage handling, every model is produced to meet globally recognised benchmarks for electrical safety, mechanical reliability, and environmental responsibility. The following standards and certifications apply to this pump series:

European Conformity (CE): The CE mark confirms that the pump fully complies with European Union directives for electrical safety, mechanical construction, and environmental compatibility. It signifies that the Davey single channel impeller submersible pump has been assessed for reliable submersible operation, ensuring user safety and energy-efficient performance throughout its service life.

Geprüfte Sicherheit, GS (TÜV022849EA): The GS mark, awarded by TÜV under the German Product Safety Law (ProdSG), verifies that this pump range has undergone independent third-party testing. This certification provides assurance of structural strength, safe electrical insulation, and long-term durability, particularly in challenging wastewater and sewage pumping conditions.

Electromagnetic Compatibility (EMC) Compliance: Certified by the Australian Communications and Media Authority (ACMA), this compliance ensures the pump neither produces nor is affected by electromagnetic interference.

Standards Australia: Certification under Standards Australia confirms that the S Series meets all essential national requirements for safety, construction quality, and hydraulic efficiency.

- AS/NZS3000 Sub-Clause: Confirms that electrical wiring, insulation, and grounding systems meet Australian safety codes for submersible installations.

- AS4020 Sub-Clause: Verifies that all wetted materials comply with Australian standards, ensuring environmental safety and suitability for use in wastewater transfer systems.

New Zealand Standards: The S Series also meets equivalent New Zealand compliance for electrical and mechanical performance, guaranteeing dependable operation across the country’s diverse wastewater and effluent systems.

- NZS4020: Equivalent to AS4020, confirming that all material components maintain environmental integrity and long-term safety in local wastewater applications.

Sump pump selection guide

This sump pump selection guide helps identify the right pump based on fluid type, from clear rainwater to heavy slurries. Each series is designed for specific conditions, ensuring optimum hydraulic performance and longevity. Among them, the single channel impeller submersible pump (S Series) stands out as the ideal choice for wastewater, effluent, and semi-screened sewage with up to 10% soft solids. Its open impeller handles suspended materials efficiently without clogging, offering reliable flow, higher pressure capability, and durable performance in demanding residential, commercial, or light industrial drainage applications.

| Suitable Fluid | Rainwater | Drainage | Dirty Water / Greywater | Wastewater / Effluent / Sewage | Sludge / Slurries | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pumps | D23A/B, D42A/B & D53A/B | Small Double Case Submersible Water Pump Models (DC10) | Small Dewatering Pump Models (D10 & D15) | Double Case Models (DCS40 & Above) | Dewatering Pump Models (D25 & Larger) | Single Channel Models (S) | Vortex Models (V) | Cutter Models (K) | Grinder Models (G) | Sludge & Slurry Models (KZN) |

| Fluids / Application | ||||||||||

| Fountains | X | ✔ | — | |||||||

| Rainwater (e.g. tank to garden or home) | ✔ | — | ✔ | — | ||||||

| Stormwater and surface run off water | ✔ | X | ✔ | |||||||

| Greywater with nil or few soft solids (e.g. septic tank pump-outs) | ✔ | X | ✔ | |||||||

| Dirty water with less than 1% small hand solids – some wear can be expected (e.g. site dewatering, swimming pool drainage, stormwater pumping) | ✔ | X | ✔ | X | ✔ | |||||

| Water with up to 10% soft solids in suspension – max. particle size is 80% of pump outlet (e.g. semi screened raw sewage, stock effluent, grease traps) | X | ✔ | ||||||||

| Water with medium volumes of hair in suspension (e.g. greywater, abattoir wash down, dog washing, animal washing) | X | ✔ | X | |||||||

| Water with stringy materials in suspension (e.g. laundromats, cotton & wool mills, food factories) | X | ✔ | X | |||||||

| Raw sewage including sanitary products | X | ✔ | X | |||||||

| Slurries with up to 35mm particles in suspension up to 70% by weight (e.g. sand and slurries, building site water, mine site water) | X | ✔ | ||||||||

Single channel open impeller for precision flow

At the heart of every Davey submersible sewage pump lies a single channel open impeller, engineered for smooth and uninterrupted water flow. This centrifugal pump design delivers high hydraulic efficiency while reducing the risk of clogging, even when handling wastewater, sludge, or semi-solid materials. The open impeller vane allows the free passage of soft solids, up to 80% of the discharge size, making it ideal for demanding drainage, wastewater, and effluent transfer applications. Its hydraulic geometry minimises turbulence and energy loss, improving both performance and reliability. Designed to operate efficiently under varying head conditions, this impeller ensures consistent water movement in sump pits, stormwater basins, and treatment systems, embodying the precision and durability expected from Davey’s wastewater engineering.

Durable cast iron and 316 stainless steel construction

Reliability starts with strength, and the Davey single channel impeller submersible pump delivers both through its solid construction.

Each unit is built from premium cast iron or marine-grade stainless steel, ensuring durability in harsh wastewater and drainage environments. The cast iron models offer proven toughness against mechanical wear, while the 316 stainless steel versions provide superior corrosion resistance in saline, acidic, or chemically aggressive fluids. Both materials undergo precision machining for optimal hydraulic alignment and reduced vibration during continuous operation.

With reinforced casing, impeller housing, and discharge outlet, the pump resists abrasion and structural distortion under high pressure. This robust construction ensures structural stability, long service life, and dependable performance under prolonged submersion.

Double mechanical shaft seal in oil bath for advanced protection

For continuous-duty operation, the Davey submersible sewage pump employs a double mechanical shaft seal system immersed in an oil bath. This configuration ensures superior sealing integrity, keeping contaminants, grit, and water out of the motor chamber.

The seal set combines silicon carbide and ceramic faces, materials selected for their hardness, thermal stability, and resistance to abrasion. A secondary sand slinger lip seal provides additional protection, guarding the motor against fine slurry particles and extending service intervals.

Included In The Box

Single Channel Impeller Submersible Water Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us