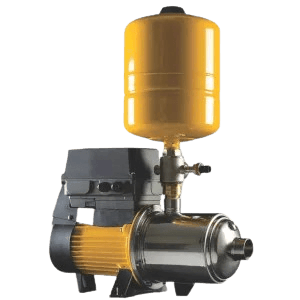

Davey Malaysia / Home / Water Pump / Davey TotalFlo Water Pump

Davey's TotalFlo Water Pump

Key features:

- Standard automatic pressure system type.

- Suitable for smaller households (2-4 shower heads with 4-7 pipes).

– Has a sump pump type for flood management & drain clearing. - For housing and garden use.

- 24 months warranty for pump, motor & controller.

(24 + 6 additional months with e-Warranty scheme) - Fixed pressure setting on every usage.

- Easy installation, no setting required.

All Versions of Davey's TotalFlo Water Pump

Overview of Davey's TotalFlo Water Pump

Amid low residential areas come a unique water management issue to resolve, and Davey Water Products have decided to take on the mantle to address this – an incident as common a social issue found in Malaysia: on-going droughts, floods by downpour, and abundantly found clogged drains, which became a focal point to appeal centrifugal pumps at. The outcome as devised by Davey’s mechanical engineering division is the TotalFlo electropump, ever-simple in design that remains cost-saavy for the budget-tight consumers, and it’s built on end for the low-to-mid sized households as well as another iteration purely for flood control means.

Three of its models (single phase jet pumps and the multistage type) is in-line of the Home Pressure System arrangement, the simplicity of Davey’s TotalFlo water pump can be said with an analogy of the easy plug-and-play. Fitted just beside and under a water tank for a constant self-priming state, once the plug is attached onto the socket, the TotalFlo pump becomes constantly ready to be used, 24/7. Automatic in running just as Davey’s centrifugal pump adheres to the current global benchmark standard of electrotechnology usage, to facilitate pressurised water any time a faucet is opened, or even filling up the reservoir of a toilet for flushing, and also opening the shower head, the drop in water level that is in oversight by the TotalFlo electric pump’s sensor would have itself enabled to maintain hydrating force. The last model is the sump pump alternative, and this TotalFlo is a submersible one to remove excess water out, which is plainly achieved by a control point monitored by the float switch.

In Davey’s particular growth of Southeast Asia only, all household versions of the TotalFlo water pump (with the exception of sump pump only) is warranted for 24 months, with an extra eligibility of 6 months from the e-Warranty scheme to replace any internal parts being damaged by manufacturing defect.

Davey's TotalFlo Water Pump Design Varieties

| Pump Model | Product Code (SKU) |

|---|---|

| TotalFlo Jet Pump Version |

|

| TotalFlo Multistage Pump Version | TF117MS-18 |

| TotalFlo Sump Pump Version |

|

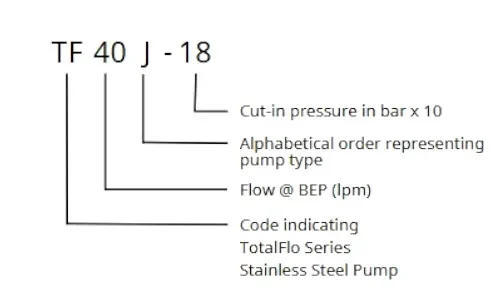

Method of Identification

A unique identifier methodology has been exercised throughout Davey Water Products, and this is the high point of delivering and serving the supply chain for over 90 years, cataloguing every centrifugal pumps and other aquatic treatment merchandises readily supplied. In the case of the TotalFlo water pump, the serialisation begins with:

- An abbreviation of the actual pump name.

- The numerical figure of the volumetric flow rate found.

- An alphabetical representation of the TotalFlo build-up.

- The total cut-in pressure in bar multiplied by 10.

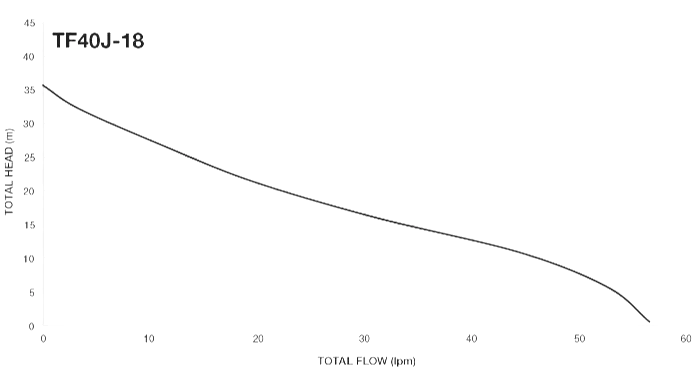

Basing off the example given in the right image diagram, the TotalFlo water pump listed has an SKU of TF40J-18, where ‘TF‘ signifies the product name, 40 litre per minute (lpm) as its output given, a ‘J‘ that actualises its pump type, which is the jet form, and also the bar cut-in pressure at 180 kPa.

For the alphabetical pattern, it must be mentioned that an ‘S‘ character can be found that signifies the TotalFlo sump pump iteration, whereas the ‘MS‘ would constitute multistage.

The fixated sequencing stands one-of-a-kind for each of the water pumps found, which assays for ease of reference to retrieve the specific and necessary components whenever repairing services are conducted by Davey Malaysia’s retailer.

Outside from that, the identification numbers are deployed for tracking purposes across the TotalFlo water pump distributing and delivery network, whereas internally, this permanent serial number found is applied to fetch the accurate centrifugal pump amid purchasing order reasons. The practised is centralised because every Davey offices features an in-house wide range of inventory sorting where serialisation is deemed necessary for electropump retrieval.

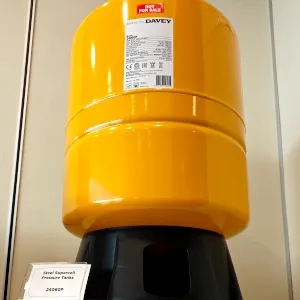

Attachment

Pressure Tank

A pressure tank as an accessorised option can be integrated onto the TotalFlo water pump. In the case of Davey, up to 8 litre (2.11 gallons) may be installed to prevent continuous pump cycling.

Pump Cycling Prevention: The pressure tank serves as a buffer where aquatic rations are stored, and plays a crucial role on any water system as to prevent repeated start-stop momentum that can fracture Davey’s TotalFlo pump. In addition, the phenomena of water hammer becomes thwarted as the gush of hydration becomes released from reserve upon open piping, than causing unnecessary stress onto the TotalFlo centrifugal pump and altogether damaging the water supply network.

As the pressure tank features an inner diaphragm (and this may also be known as a rubber sheet, or a bladder) separating an upper layer consisting of pure air whereas the bottom section stockpiles water, as h2o becomes kept, this pushes up against the artificial diaphragm that compresses the atmosphere above it, producing the tension of pressurised water as needed instead of relying on the TotalFlo water pump frequently.

Regime For Environmentalism: Greenhouse emission is inhibited by reducing the required amount of activation and deactivation of Davey’s TotalFlo water pump, resulting in less energy usage, and lesser carbon creation in a specified period.

Water Pump Certifications

A variety of consumer-based and manufacturing-related accreditations has been awarded onto Davey and for the TotalFlo water pump, denoting a prioritisation for the safety of end users and marking an important trust that is a buying factor whenever a booster pump becomes chosen.

Besides that, as Davey Water Products acquire the necessary certifications across different regional legislation, these are also permissible icons that are required to allow exporting of the TotalFlo centrifugal pump onto different territories and continents respectively.

SGS Approved: The strigent examination of electrical protection as scrutinised by Société Générale de Surveillance to detect any failure in Davey’s TotalFlo water pump as a home appliance test, where the entryway becomes cleared to signify that the pump motor cables are properly insulated to put a full stop on potential electrocution and other galvanic hazards upon operation.

European Standards (ES): The technical uniformity that was first introduced and centralised among the European organisations for goods, services, and procedures in adherence to match the people’s welfare, the quality of production, eco-friendliness, and the necessary tabulation as well as data-backed findings of performance has been met by Davey’s TotalFlo water pump. The acquisition of this credential paves the definite way into the European soil where all of Davey’s electropumps and other relatable water merchandises can be distributed and used.

A particular importance behind the European Standards compliance is the eventual synergy recognition between technologies found, and as the cert becomes bestowed onto the TotalFlo centrifugal pump, this further indicates that it can be intergrated with other producer’s inventions to work together. For example: a pressure switch of another maker can be attached into the TotalFlo pump for one’s water treatment at home. Additionally, the ‘CE‘ marking is imprinted as to convoy the essential European Union regulations were met.

International Electrotechnical Commission (IEC): The main authority overseeing all voltaic causes, computing work, and associated advancement, and Davey’s TotalFlo water pump overlaps with that of its regulation. This is primarily the employment component of the pump’s engine, with its requirement being electrically-powered that is found associated with the IEC. Garnering this certification allows Davey to be recognised and compliant universally, permitting for even wider scale of TotalFlo water pump trading as distributors seek manufacturers of Mutual Recognition Arrangements (MRAs).

Standards Australia (AS): A voluntary benchmark set by a non-profit organisation in the homelands of Davey Water Products. Regularly referenced by the sovereign Australian legislation, only by conforming onto this independent institution will the local selling of items, including the TotalFlo pump, becomes allowed. It must be hinted that the Australian Standard is THE point of reference of a non-governmental entity at its pinnacle, which is why Davey is more than happy to follow through its schematic.

- AS4020:2005: Gathering the specificity encompassing all there is towards any produce and solution inventions that are in direct contact with any water source, it’s studied and discovered that Davey’s TotalFlo water pump does not pose any forms of risk—no matter how small the incident—towards the human health. No further changes in the status of the reservoir were also ultimately found, in which this electric pump is granted the AS4020:2005 sub-clause acknowledgement. The formal inspection determines different parts centred to the TotalFlo water pump, which covers the pipes, fittings, coatings, seals, and even the pressure tank (if it is attached).

Standards New Zealand: Similar in naming with that of the Australian Standards, the Standards New Zealand is the country’s official body for developmental expansion, reporting, and preservation of quality guidelines for all industrial use – including the working principle of centrifugal pumps within the mechanical engineering sector. As it is a ruling jurisdiction for technical specifications, this is vital for Davey to meet to penetrate into another district of agriculture, deep well, irrigation, swimming pool coverage, fountain motors and other niche of water pump applications.

ISO 9001: The grandest of framework widely embraced by manufacturers, the 9001 clause of the International Standard of Organisation offers a supervision in the creation of Davey’s TotalFlo centrifugal pumps, setting expectations where the making in each and every step becomes documented in the drawing of production blueprints, finalising the consistency as intended to be sought for in the supply chain. Moreover, the confidence where uninterrupted improvements to reach a unique proposition level of pump products is also emphasised.

ISO 14001: The 14001 paragraph of the ISO revolves around the sustainable administration of Davey’s TotalFlo pump construction. The honour concluded that the fabrication processes are in consideration of energy consumption, the ethical littering of byproducts amid the forming of the electropump, the prerequisite steps of pollution control, as well as the rate of resource allocation poured in. The labelled certification marks an important alignment towards a greener future, as well as the steps Davey Malaysia has taken to exercise it.

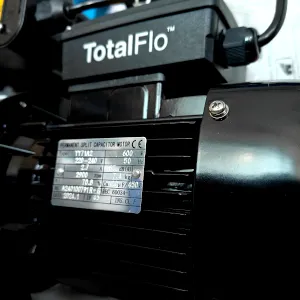

Consistent Pressure Motor Pump

Entailing a value-for-cost water pump effort for small housing, design engineers have planned this version of the Home Pressure System series to include a basic motor that moves in constant speed.

The engine fitted into the TotalFlo water pump is niche-specialised for compact household, producing the needed pressure with moderate noise-level.

No-Brainer Installation: As effortless as simply just plugging the three-pin plug into the wall socket, once the switch is flipped open, the TotalFlo electropump is always ready to run its cycle.

Self-Priming: The priming motor is self-sufficient to remove trapped air on its own, and slow but steadily would its suction port becomes soaked completely to release a steady pressure state. This can be obtained only if Davey’s TotalFlo water pump becomes nested under the water tank to draw in hydration continuously. In this configuration, a net positive suction head (NPSHr) has better chances become realised.

Demonstrated Technology: Davey’s TotalFlo water pump is equipped with a motor that is backed by a scientifically-proven evidence to swirl aqua centrifugally, the result equates to not needing to spin the wheels via research expenditure by using what already works.

Technical Motor Specifications For Household Pumps

| Stages | |

|---|---|

| Product code (SKU) | Single stage:

|

| Multistage: TF117MS-18 | |

| Motor size | Single stage:

|

| Multistage: 750W | |

| Voltage | 220 – 240V |

| Frequency | 50 Hz |

| Phase | Single |

| Current | Single phase:

|

| Multiphase: 4.0A | |

| Insulation | Class F |

| IP | 45 |

| Power lead | 1.8m with C38 3-pin plug |

| Nominal speed | Single phase:

|

| Multi-phase: 2,860 rpm | |

| Inlet size | 1″ BSP F |

| 1.25 inch BSP F | |

| Outlet size | 1″ BSP M |

| Max. head | 35m (114.83 ft) |

| 41m (134.51 ft) | |

| Max. flow | Single Stage:

|

| Multistage: 117L per minute | |

| Max. temperature | 35°C (41°F) |

| Max. ambient temperature | 40°C (104°F) |

| Cut in pressure | 180 kPa (1.8 bar) |

| Wet end casing | 304SS |

| Noise ratings | Single Phase:

Multistage: 67.8 dB |

*The W in motor size is referred to watt consumed.

*V is the abbreviation of voltage.

*Hz is the hertz used in frequency.

*The ‘A’ alphabet means Ampere.

*In nominal speed, rpm refers to revolution per minute.

*BSP F stands for British Standard Pipe Female.

*Maximum head is in metres, where ft appear for foot in measurement.

*Maximum flow in lpm is defined for Litre per minute.

*The ambience temperature of °C is degree celsius.

*°F is degree Fehrenheit.

*dB is the reference to Decibel.

Technical Motor Specifications For Sump Pump Version

| Sump Pump | |

|---|---|

| SKU |

|

| Voltage | 220 – 240V |

| Frequency | 50 Hz |

| Phase | Single |

| Insulation | Class F |

| IP | X8 |

| Nominal speed | 2,850 rpm |

| Auto float operation | Yes |

| Particle size | 18mm (soft & in water) |

| Outlet size | 2″ BSP F (1/4 reducer included) |

| Particle size | 18mm (soft & in water) |

| Max. head |

|

| Max. flow |

|

| Max. water temperature | 40°C |

*The W in motor size is referred to watt consumed.

*V is the abbreviation of voltage.

*Hz is the hertz used in frequency.

*The ‘A’ alphabet means Ampere.

*In nominal speed, rpm refers to revolution per minute.

*BSP F stands for British Standard Pipe Female.

*Maximum head is in metres, where ft appear for foot in measurement.

*Maximum flow in lpm is defined for Litre per minute.

*The ambience temperature of °C is degree celsius.

*°F is degree Fehrenheit.

*dB is the reference to Decibel.

TotalFlo Water Pump For Homes In Infographic

Below is an infographic imagery that compiles the overall Home Pressure System of Davey’s centrifugal pumps found. These were carefully calculated with consideration of the piping systems available, the number of faucets and shower heads by Davey Malaysia’s in-house engineers, which is then translated into an information chart to use the correct electropump for your house. The water pump listed includes Davey’s signature DynaDrive, the Horizontal Multistage pump, as well as the TotalFlo electropump, with each of its product iteration can be viewed to use on the correctly sized place of residence.

TF40, TF50 and even TF117 range of TotalFlo water pumps can be used. With a shower sprinkler of up to 2, and a spigot of up to 4 (equivalent to a single storey dwelling), the smallest or the mid range TotalFlo pump can be considered. As the faucets and bathrooms increases up to 4x and 7x respectively, then the TF117 may be applied instead. This also equates to a one and a half (or double) storey home.

Varied Suction Inlet Sizing

The suction of the inlet port varies from one model to another. Within the water pump for house variant, Davey’s TotalFlo features:

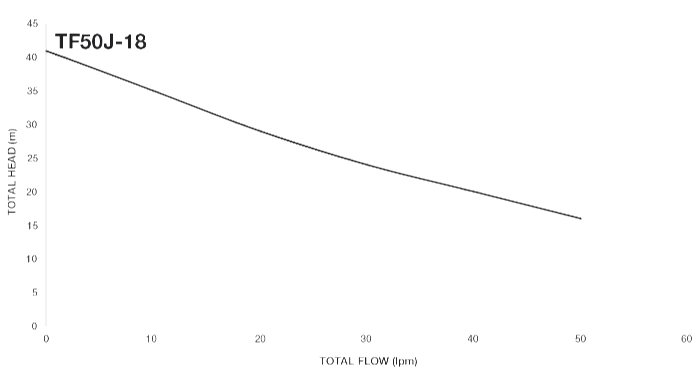

- 1 inch (25.4mm) inlet port for smaller models (TF40J-18 and also TF50J-18).

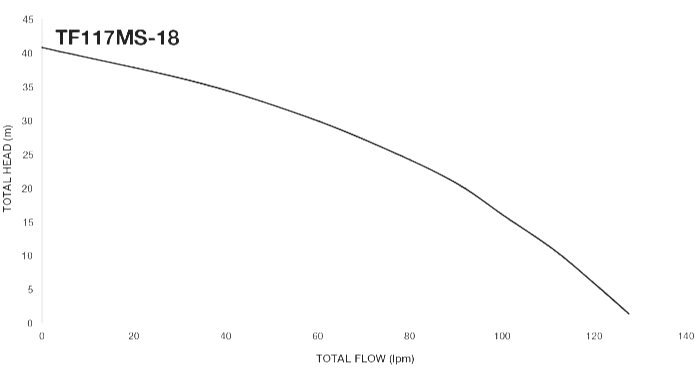

- 1.25 inch (31.75mm) inlet port attachment for the larger TF117MS-18 update.

With a fundamental duty of drawing and directing clean water into the TotalFlo centrifugal pump, pressurisation is then induced once the drench goes through the impeller within.

To the contrary, Davey’s TotalFlo of the sump pump sorting is designed to pull in wastewater, or even floods accumulated and stagnated within a sump pit, which is then re-directed elsewhere to reduce clogging.

Durable stainless steel alloy of SUS304 grading is also used, offering a lustre after polishing the TotalFlo water pump that can be aesthetically pleasing. The high resistance is needed to resist against corrosion due to being splashed and soaked all throughout the pump’s body – whether with clean water from Air Selangor (SYABAS), Penang Water Supply Corporation, or other state-level ration provider, to even murky waters as a result of debris and mud.

Under A Water Tank: The placement of Davey’s TotalFlo water pump should remain fixed and is stationed near as well as below the water tank. This is done so as to fulfill a Net Positive Suction Head (NPSHr) where an influx of filtered water rushes into the suction inlet wholefully to close the air gap in the electropump. As the centrifugal pump runs, more and more ventilation becomes removed, just as the inner dampening of the TotalFlo continues to happen that altogether mitigates cavitation. The total hydraulic circuit proceedings make it so that water pressure with this water pump is nigh-consistent.

One-Directional Flow: When running Davey’s TotalFlo water pump, the engine creates a suction force to draw in aqua and the waterlogged input goes unidirectionally only.

117MS-18 Model With Faster Self-Priming: A larger suction inlet of 1.25 inch (31.75mm) equates to having more fluids that can be drawn into the TotalFlo pump, which completes the self-priming state ever more quickly.

Upon delivering Davey’s TotalFlo water pump, a plastic cap is used to seal the inlet for the safe yardage of application. This is to prevent fine dust, or other external source from entering and damaging the inner components itself, which inhibits the centrifugal pump’s ability to function.

| Inlet and outlet information | |

|---|---|

| Inlet size | TF40J-18 & TF50J-18: 1 inch (25.4mm) BSP F |

| TF117MS-18: 1.25 inch (31.75mm) BSP F | |

| Outlet size | For all home pressure systems: 1 inch BSP M |

| Max. head | TF40J-18 only: 35m (114.83 ft) |

| TF50J & TF117MS-18: 41m (134.51 ft) |

Stainless Steel Volute Casing

Protecting and housing the internal parts in fixated alignment is the volute coverage, and being equally made under a composite alloy material, the combined metallic elements with carbon has made so that Davey’s TotalFlo water pump is ever-resistance against rust.

SUS304 is the graded metal assignment that is further used to complement the suction inlet, as well as other inside physical medium of the electropump.

With a spiral-like shape stretched out onto a cylindrical container, once dilution gets sucked in, water is directed in a swirling state where it’s pressed against the walls internally, before it becomes guided to the discharge outlet of the centrifugal pump.

The overall housing with the volute has made so that the flow rate becomes augmented to its optimal state, allowing a strong pressure to be flushed out.

External Protection: A crucial aspect of the volute casing is its barrier against both foreign force and also possible scrap from entering Davey’s TotalFlo pump. As it runs merely on clean water only, any debris, accumulated sand, dirt, and such may possibly damage the water system.

Self-Priming Guidance: Just as the volute can only hold so much volume of the water within, once it becomes completely filled where the remainder of air trapped is expelled, the TotalFlo electric pump would maintain an internal vacuum that continuously sucks in water. This is the primed state that is idealised and desired across any water pumps.

Closed Impellers And Diffusers

All household versions of the TotalFlo water pump uses a closed impeller by setup with the exception of its sewage pump veriant, which is semi-open, the functionality of this enclosing permits for better water movement efficiency, revealing stronger end pressure, flow rate and altogether reduced energy loss when pumping is active.

Two sections can be broken up with a closed impeller in application: one being the vane where liquids are swirled centrifugally happens, and the other being the cover / shroud that bounds the impeller and diffuser inside it. These are sealed into a chamber or even multiple stages (if it is multi-stage type) within any TotalFlo water pump.

Less Damage: Being sheltered by a closing cover, Davey’s TotalFlo water pump are less prone to wreckage from external debris and the likes—especially when the sump pump is used for sludge removal.

Mitigating Cavitation: While having a better flow rate, the assistance of the closing mechanism minimises cavitation from happening, resulting in even better endurance of the TotalFlo electropump.

Smoothened: As this area is where h2o primarily drifts through, every element of the closed impeller is polished to its smoothest surface in order to reduce friction upon contact, ultimately enhancing the water stream and also eliminating unnecessary power consumption of Davey’s TotalFlo pump.

Better Thermodynamics Performance: A more orderly flow state is reached with the closed impeller. This is because entropy (an event where loss of energy can be found due to randomised movements) is lessned, equating to a better performance.

Impellers And Diffusers In Davey's TotalFlo Multistage Water Pump Variant

The TF117MS-18 of Davey’s TotalFlo pump variation encloses 4 staging bodies within, or in other words, 4 lines of impellers and diffusers found which are separated by spacers in-between.

Impellers In TotalFlo Sump Pump Alternative

The TotalFlo sump pump variation also uses the very same stainless steel impeller (although singular in stage and semi-open in class) in order to move wastewater and/or for flood management.

This is a pre-requisite as contaminated water source tend to be acidic and can corrode normal metal out. Nevertheless, it’s a matter that was taken into account by Davey’s engineers for the TotalFlo electropump as part of materials science.

SUS304 is also equally used on both the TotalFlo multistage pump and the sump pump to ensure durability for the long haul.

To begin, the engine would first convert electrical energy onto mechanical with its rotor spinning, and as the internal impeller becomes soddened, the water pulled into and translating the very spinning segment gain centrifugal force that was generated by the rotation. As the impeller spins, water is then pushed outward towards and against the outer walls that is the centrifugal pump’s volute casing. During this process, kinetic energy is gained from the increased velocity.

As hydration exits the impellers and the diffuser, it would be pressed against the pump’s casing which turns the energy into pressure before exiting into the discharge outlet. The overall conversion of energetic states happens within the diffuser found—which is locked into place by the staging body of the volute—and this is known process defined as the Bernoulli’s principle for the happening.

With each stages in the volute’s passage, the water becomes pressurised even more before it leaves through the outlet, and part of the process aiding to create the vacuum suction are these impellers found attached onto the shaft.

Gasket, Backplate, And Mechanical Seal

Just before the rear end that sits the motor, a crucial power-driven machine running on electricity should be safeguarded from unnecessary sprinkle, spillage of water, or any form of wetness that may pose a threat to Davey’s TotalFlo water pump (and likewise, the user). Because of this, a defensive panel known as the backplate is the final line of defense installed that secures the electrotechnology to run seamlessly, and also where it would support the outflow of hydration onto the centrifugal pump’s discharge outlet.

A gasket made in rubber must first be screwed into place, where it would then hold every other pump components (volute, rotating shaft, backplate, and even the motor) rigidly. The gasket serves the following:

Vibration Absorption: One of the benefits is its ability to dampen excessive vibration, which cuts down unnecessary mechanical wear and stress, and also among the parts that contribute to the TotalFlo water pump’s longer shelf-life.

Noise Reduction: Just as it absorbs vibrational movements, sound also becomes dull as alloy-to-alloy contact in this electropump becomes prevented.

Ahead of the backplate is a mechanical seal, also found attached onto the shaft, the primary purpose is its sealing ability to inhibit water leakage directly into the TotalFlo pump’s engine.

O-Ring, Spacers And Washer

Various sizing of the O-ring application being made in EPDM (ethylene propylene diene monomer) is airtight and water tight shut into various parts of Davey’s TotalFlo water pump.

The polymer, EPDM, becomes chosen over neoprene as a result of high temperature resistance, which may be prevailing during elongated operation and across viscous liquid removal in drainage pumps (sticky slurry may drag the efficiency of water pumps, generating even more heat altogether).

This is added with an extra and final layer of protection, where the washer is finally used—being placed ahead of the mechanical seal part—to also offer another tight blockage to hinder water from entering. Load distribution can also be observed from the washer as it prevents grinding, while enabling uniformity among the activity of other bits to run concurrently.

Spacers in TotalFlo Multistage Water Pump Iteration: Upon cross section viewing, a countable number of spacers can be discovered, and this is designed into placement to offer an adequate room where the staging chambers would run properly and without rubbing against one another.

TotalFlo Water Pump's Electrical Data & Operating Limits (Housing Use)

| TF40J-18 | TF50J-18 | TF117MS-18 | |

|---|---|---|---|

| Motor size | 370W | 600W | 750W |

| Voltage | 220-240V | ||

| Frequency | 50 Hz | ||

| Current | 1.95A | 2.7A | 4.0A |

| Phase | Single | ||

| Insulation | Class F | ||

| IP | 45 | ||

| Power lead | 1.8m (3.28 ft) | ||

| Nominal speed | 2,820 rpm | 2,900 rpm | 2,860 rpm |

| Inlet size | 1 inch (25.4mm) BSP F | 1.25 inch (31.75mm) BSP F | |

| Outlet size | 1 inch (25.4mm) BSP M | ||

| Max. head | 35m (114.83 ft) | 41m (134.51 ft) | |

| Max. flow | 40 Litre per minute (10.57 gallons per minute) | 50 Litre per minute (13.21 gallons per minute) | 117 Litre per minute (30.91 gallons per minute) |

| Max. water temp. | 35°C (95°F) | ||

| Max. ambient temp. | 40°C (104°F) | ||

| Cut in pressure | 180 kPa (1.8 bar) | ||

| Wet end casing | 304 Stainless Steel | ||

| Noise ratings | 69.4 dB | 72.8 dB | 67.8 dB |

*Watt is shortened into ‘W’.

*V stands for voltage.

*Hz is defined for the number of Hertz.

*Ampere is referred to as ‘A’.

*Metre is symbolised as ‘m’.

*Feet is abbreviated as ft.

*Revolution per minute, is also known as cycles per minute, is coined as ‘rpm’.

*Millimetre is ‘mm’.

*BSP F has the meaning of British Standard Piping Female.

*BSP M explains to be British Standard Piping Male.

*Degree Celsius is represented with °C.

*Degree Fehrenheit is signified to °F.

*Decibel is shortened into ‘dB’.

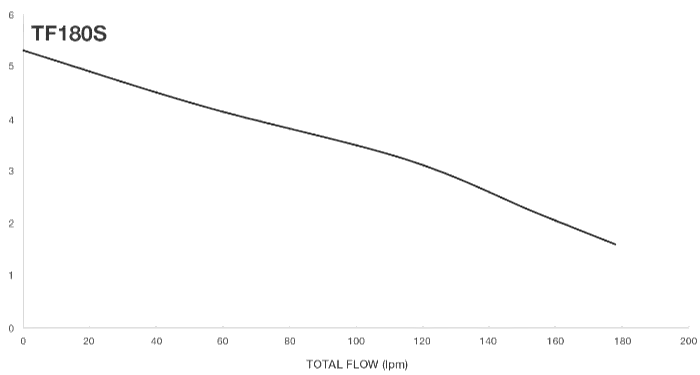

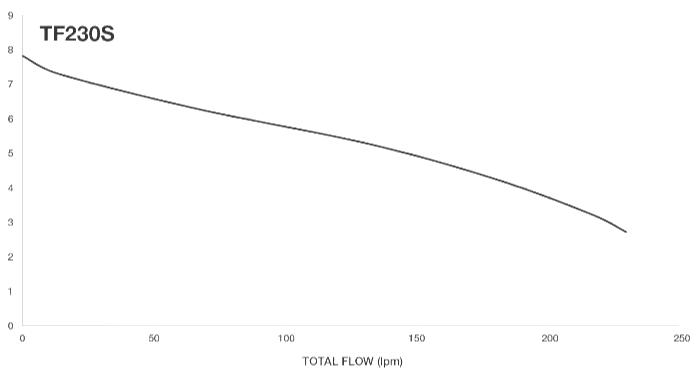

Davey's TotalFlo Household Water Pum's Hydraulic Performance

TotalFlo Sump Pump's Electrical Data & Operating Limits

| AS33 | AS75 | |

|---|---|---|

| Motor size | 330W | 750W |

| Voltage | 220-240V | |

| Frequency | 50 Hz | |

| Phase | Single | |

| Insulation | Class F | |

| IP | X8 | |

| Nominal speed | 2,850 rpm | |

| Auto flat operation | Yes | |

| Particle size | 18mm (soft & in water) (0.71 inch) | |

| Outlet size | 2 inch / 50.8mm BSP F (1.25 inch / 31.75mm reducer included) | |

| Max. head | 5m (16.4 ft) | 8m (26.25 ft) |

| Max. flow | 180 Litre per minute (47.55 gallons per mintue) | 230 Litre per minute (60.76 gallons per minute) |

| Max. water temperature | 40°C (104°F) | |

*Watt is interpreted as ‘W’.

*Voltage here is symbolised as ‘V’.

*Hertz is interchanged into Hz.

*Revolution per minute, or RPM, is also known as cycles per minute.

*Millimeter is written as mm in this sump pump’s tabulation.

*Meter is alphabeticised as ‘m’.

*Feet is ‘ft’ as its short-formatting.

Davey's TotalFlo Submersible Water Pump's Hydraulic Performance

Included In The Box

TotalFlo Water Pump

User Manual

Proof of Purchase

24 Months of Manufacturer Warranty (Increased by Another 6 Months with e-Warranty Scheme)

Downloads

All Household Water Pumps In Grouped Product View

Contact Us