Davey Malaysia / Home / Water Pump / Davey VM Vertical Multistage Water Pump

Davey's VM Vertical Multistage water pump

Key features:

- Standard automatic pressure system type.

- Suitable for apartments, condominiums, offices, and industrial use.

- 12 months warranty for pump & motor.

- Fixed pressure setting on every usage.

- Easy installation, no setting required.

All versions of Vertical Multistage centrifugal pump

Single Phase

Three Phase

Liquid End

Davey's VM Vertical Multistage water pump overview

In today’s world, a reliable water system is essential not just for comfort but for productivity, efficiency, and sustainability. Whether you are operating a busy commercial complex, an industrial plant, or an apartment block, ensuring steady water pressure can be the difference between a smooth day and a frustrating one. The VM Vertical Multistage water pump by Davey has been designed precisely with these challenges in mind, offering robust engineering quality backed by Davey’s long-standing reputation in dependable pumping solutions.

At the heart of this pump range is its Vertical Multistep centrifugal pump design, where multiple impellers are stacked vertically to deliver consistent high pressures with compact footprint efficiency. Unlike conventional setups, the VM series brings the reliability of electropump engineering into a solution that saves floor space and simplifies pipework.

Each pump within the VM range is meticulously engineered from stainless steel, making it highly resistant to corrosion and abrasion. It is vital for long service life in industrial and commercial installations. With precision-built components including a mechanical seal, shaft, and high-efficiency impeller, the VM offers the resilience needed for constant operation. It also integrates seamlessly into booster and pressure pump systems, supported by Davey’s extensive catalogue of accessories and easy-to-follow installation guidelines. From water supply in offices and high-rise apartments, to irrigation in agriculture, or skid-mounted industrial systems, the VM series proves that a well-engineered vertical inline pump can make water work smarter, day after day.

Choosing the right pump

The VM series comes in multiple sizes and capacities, ensuring there is a solution for every application. Capacities range from 1 to 240 , while pressure heads reach up to 230 metres. Motor sizes extend from 0.37 kW for compact duties to 110 kW for demanding industrial applications.

With such a broad spectrum, consultants and installers can select a vertical centrifugal pump configuration optimized for their system. For example, a VM1 is ideal for compact water supply duties, while a VM200 suits large-scale industrial booster sets.

Every specification is laid out clearly in Davey’s catalogue, making model selection straightforward for designers, contractors, and end-users.

Vertical Multistage – 1 Phase

| Model No. | Motor kW (P2) | Flange Connection | Counter Flange Tapping |

|---|---|---|---|

| VM1-11M1 | 0.55 kW | DN25 PN25 | 1 1/4″ BSP(F) |

| VM1-15M1 | 0.75 kW | ||

| VM1-17M1 | 1.1 kW | ||

| VM1-21M1 | 1.5 kW | ||

| VM1-23M1 | 1.5 kW | ||

| VM1-25M1 | 1.5 kW | ||

| VM3-8M1 | 0.75 kW | DN25 PN25 | 1 1/4″ BSP(F) |

| VM3-12M1 | 1.1 kW | ||

| VM3-15M1 | 1.5 kW | ||

| VM3-17M1 | 2.2 kW | ||

| VM3-19M1 | 2.2 kW | ||

| VM3-23M1 | 2.2 kW | ||

| VM5-5M1 | 0.75 kW | DN32 PN25 | 1 1/4″ BSP(F) |

| VM5-7M1 | 1.1 kW | ||

| VM5-8M1 | 1.1 kW | ||

| VM5-10M1 | 1.5 kW | ||

| VM5-12M1 | 2.2 kW | ||

| VM5-14M1 | 2.2 kW | ||

| VM5-16M1 | 2.2 kW | ||

| VM10-4M1 | 1.5 kW | DN40 PN25 | 1 1/2″ BSP(F) |

| VM10-5M1 | 2.2 kW | ||

| VM10-6M1 | 2.2 kW |

Vertical Multistage – 3 Phase

| Model No. | Motor kW (P2) | Flange Connection | Counter Flange Tapping |

|---|---|---|---|

| VM3-8M3 | 0.75 kW | DN25 PN25 | 1 1/4″ BSP(F) |

| VM3-12M3 | 1.1 kW | ||

| VM3-15M3 | 1.5 kW | ||

| 3M17M3 | 2.2 kW | ||

| VM3-19M3 | 2.2 kW | ||

| VM3-23M3 | 2.2 kW | ||

| VM3-29M3 | 3.0 kW | ||

| VM5-3M3 | 0.55 kW | DN32 PN25 | 1 1/4″ BSP(F) |

| VM5-4M3 | 0.55 kW | ||

| VM5-5M3 | 0.75 kW | ||

| VM5-7M3 | 1.1 kW | ||

| VM5-8M3 | 1.1 kW | ||

| VM5-10M3 | 1.5 kW | ||

| VM5-12M3 | 2.2 kW | ||

| VM5-14M3 | 2.2 kW | ||

| VM5-16M3 | 2.2 kW | ||

| VM5-20M3 | 3.0 kW | ||

| VM5-22M3 | 4.0 kW | ||

| VM10-3M3 | 1.1 kW | DN40 PN25 | 1 1/2″ BSP(F) |

| VM10-4M3 | 1.5 kW | ||

| VM10-5M3 | 2.2 kW | ||

| VM10-6M3 | 2.2 kW | ||

| VM10-7M3 | 3.0 kW | ||

| VM10-8M3 | 3.0 kW | ||

| VM10-9M3 | 4.0 kW | ||

| VM10-10M3 | 4.0 kW | ||

| VM10-12M3 | 5.5 kW | ||

| VM10-14M3 | 5.5 kW | ||

| VM10-16M3 | 7.5 kW | ||

| VM20-18M3 | 7.5 kW | ||

| VM10-20M3 | 7.5 kW | ||

| VM15-3M3 | 3.0 kW | DN50 PN25 | 2″ BSP(F) |

| VM15-4M3 | 4.0 kW | ||

| VM15-5M3 | 4.0 kW | ||

| VM15-6M3 | 5.5 kW | ||

| VM15-7M3 | 5.5 kW | ||

| VM15-8M3 | 7.5 kW | ||

| VM15-9M3 | 7.5 kW | ||

| VM15-10M3 | 11 kW | ||

| VM15-12M3 | 11 kW | ||

| VM15-14M3 | 11 kW | ||

| VM20-1M3 | 1.1 kW | DN50 PN25 | 2″ BSP(F) |

| VM20-2M3 | 2.2 kW | ||

| VM20-3M3 | 4.0 kW | ||

| VM20-4M3 | 5.5 kW | ||

| VM20-5M3 | 5.5 kW | ||

| VM20-6M3 | 7.5 kW | ||

| VM20-7M3 | 7.5 kW | ||

| VM20-8M3 | 11 kW | ||

| VM20-10M3 | 11 kW | ||

| VM20-12M3 | 15 kW | ||

| VM20-14M3 | 15 kW | ||

| VM20-17M3 | 18.5 kW | ||

| VM32-2-2M3 | 3.0 kW | DN65 PN25 | 2 1/2″ BSP(F) |

| VM32-3M3 | 5.5 kW | ||

| VM32-4M3 | 7.5 kW | ||

| VM32-5M3 | 11 kW | ||

| VM32-6M3 | 11 kW | ||

| VM32-8M3 | 15 kW | ||

| VM32-10M3 | 18.5 kW | ||

| VM32-12M3 | 22 kW | ||

| VM42-1-2M3 | 4.0 kW | DN80 PN25 | 3″ BSP(F) |

| VM42-2M3 | 7.5 kW | ||

| VM42-3M3 | 11 kW | ||

| VM42-4M3 | 15 kW | ||

| VM42-5M3 | 18.5 kW | ||

| VM42-6M3 | 22 kW | ||

| VM42-7M3 | 30 kW | ||

| VM42-8M3 | 30 kW | ||

| VM42-9M3 | 37 kW | ||

| VM42-10M3 | 37 kW | ||

| VM65-2-2M3 | 7.5 kW | DN100 PN25 | 4″ BSP(F) |

| VM65-2M3 | 11 kW | ||

| VM65-3-1M3 | 15 kW | ||

| VM65-4-2M3 | 18.5 kW | ||

| VM65-4M3 | 22 kW | ||

| VM65-5-1M3 | 30 kW | ||

| VM65-6-2M3 | 30 kW | ||

| VM65-6M3 | 37 kW | ||

| VM65-7-1M3 | 37 kW | ||

| VM90-2M3 | 15 kW | DN100 PN25 | 4″ BSP(F) |

| VM90-3-2M3 | 18.5 kW | ||

| VM90-3M3 | 22 kW | ||

| VM90-4M3 | 30 kW | ||

| VM90-5M3 | 37 kW | ||

| VM90-6M3 | 45 kW |

| Model No. | Motor kW (P2) | Flange Connection | Counter Flange Tapping |

|---|---|---|---|

| VM3-8M3 | 0.75 kW | DN25 PN25 | 1 1/4″ BSP(F) |

| VM3-12M3 | 1.1 kW | ||

| VM3-15M3 | 1.5 kW | ||

| 3M17M3 | 2.2 kW | ||

| VM3-19M3 | 2.2 kW | ||

| VM3-23M3 | 2.2 kW | ||

| VM3-29M3 | 3.0 kW | ||

| VM5-3M3 | 0.55 kW | DN32 PN25 | 1 1/4″ BSP(F) |

| VM5-4M3 | 0.55 kW | ||

| VM5-5M3 | 0.75 kW | ||

| VM5-7M3 | 1.1 kW | ||

| VM5-8M3 | 1.1 kW | ||

| VM5-10M3 | 1.5 kW | ||

| VM5-12M3 | 2.2 kW | ||

| VM5-14M3 | 2.2 kW | ||

| VM5-16M3 | 2.2 kW | ||

| VM5-20M3 | 3.0 kW | ||

| VM5-22M3 | 4.0 kW | ||

| VM10-3M3 | 1.1 kW | DN40 PN25 | 1 1/2″ BSP(F) |

| VM10-4M3 | 1.5 kW | ||

| VM10-5M3 | 2.2 kW | ||

| VM10-6M3 | 2.2 kW | ||

| VM10-7M3 | 3.0 kW | ||

| VM10-8M3 | 3.0 kW | ||

| VM10-9M3 | 4.0 kW | ||

| VM10-10M3 | 4.0 kW | ||

| VM10-12M3 | 5.5 kW | ||

| VM10-14M3 | 5.5 kW | ||

| VM10-16M3 | 7.5 kW | ||

| VM20-18M3 | 7.5 kW | ||

| VM10-20M3 | 7.5 kW | ||

| VM15-3M3 | 3.0 kW | DN50 PN25 | 2″ BSP(F) |

| VM15-4M3 | 4.0 kW | ||

| VM15-5M3 | 4.0 kW | ||

| VM15-6M3 | 5.5 kW | ||

| VM15-7M3 | 5.5 kW | ||

| VM15-8M3 | 7.5 kW | ||

| VM15-9M3 | 7.5 kW | ||

| VM15-10M3 | 11 kW | ||

| VM15-12M3 | 11 kW | ||

| VM15-14M3 | 11 kW | ||

| VM20-1M3 | 1.1 kW | DN50 PN25 | 2″ BSP(F) |

| VM20-2M3 | 2.2 kW | ||

| VM20-3M3 | 4.0 kW | ||

| VM20-4M3 | 5.5 kW | ||

| VM20-5M3 | 5.5 kW | ||

| VM20-6M3 | 7.5 kW | ||

| VM20-7M3 | 7.5 kW | ||

| VM20-8M3 | 11 kW | ||

| VM20-10M3 | 11 kW | ||

| VM20-12M3 | 15 kW | ||

| VM20-14M3 | 15 kW | ||

| VM20-17M3 | 18.5 kW | ||

| VM32-2-2M3 | 3.0 kW | DN65 PN25 | 2 1/2″ BSP(F) |

| VM32-3M3 | 5.5 kW | ||

| VM32-4M3 | 7.5 kW | ||

| VM32-5M3 | 11 kW | ||

| VM32-6M3 | 11 kW | ||

| VM32-8M3 | 15 kW | ||

| VM32-10M3 | 18.5 kW | ||

| VM32-12M3 | 22 kW | ||

| VM42-1-2M3 | 4.0 kW | DN80 PN25 | 3″ BSP(F) |

| VM42-2M3 | 7.5 kW | ||

| VM42-3M3 | 11 kW | ||

| VM42-4M3 | 15 kW | ||

| VM42-5M3 | 18.5 kW | ||

| VM42-6M3 | 22 kW | ||

| VM42-7M3 | 30 kW | ||

| VM42-8M3 | 30 kW | ||

| VM42-9M3 | 37 kW | ||

| VM42-10M3 | 37 kW | ||

| VM65-2-2M3 | 7.5 kW | DN100 PN25 | 4″ BSP(F) |

| VM65-2M3 | 11 kW | ||

| VM65-3-1M3 | 15 kW | ||

| VM65-4-2M3 | 18.5 kW | ||

| VM65-4M3 | 22 kW | ||

| VM65-5-1M3 | 30 kW | ||

| VM65-6-2M3 | 30 kW | ||

| VM65-6M3 | 37 kW | ||

| VM65-7-1M3 | 37 kW | ||

| VM90-2M3 | 15 kW | DN100 PN25 | 4″ BSP(F) |

| VM90-3-2M3 | 18.5 kW | ||

| VM90-3M3 | 22 kW | ||

| VM90-4M3 | 30 kW | ||

| VM90-5M3 | 37 kW | ||

| VM90-6M3 | 45 kW |

Vertical Multistage – Liquid End

| Model No. | Motor kW (P2) | Flange Connection | Counter Flange Tapping |

|---|---|---|---|

| VM3-8ML | – | DN25 PN25 | 1 1/4″ BSP(F) |

| VM3-12ML | – | ||

| VM3-15ML | – | ||

| 3M17ML | – | ||

| VM3-20ML | – | ||

| VM3-23ML | – | ||

| VM3-29ML | – | ||

| VM5-5ML | – | DN32 PN25 | 1 1/4″ BSP(F) |

| VM5-7ML | – | ||

| VM5-8ML | – | ||

| VM5-10ML | – | ||

| VM5-12ML | – | ||

| VM5-14ML | – | ||

| VM5-16ML | – | ||

| VM5-20ML | – | ||

| VM10-4ML | – | DN40 PN25 | 1 1/2″ BSP(F) |

| VM10-5ML | – | ||

| VM10-6ML | – | ||

| VM10-7ML | – | ||

| VM10-8ML | – | ||

| VM10-9ML | – | ||

| VM10-10ML | – | ||

| VM10-12ML | – | ||

| VM10-14ML | – | ||

| VM10-16ML | – | ||

| VM10-18ML | – | ||

| VM15-3ML | – | DN50 PN25 | 2″ BSP(F) |

| VM15-4ML | – | ||

| VM15-5ML | – | ||

| VM15-6ML | – | ||

| VM15-7ML | – | ||

| VM15-8ML | – | ||

| VM20-1ML | – | DN50 PN25 | 2″ BSP(F) |

| VM20-2ML | – | ||

| VM20-3ML | – | ||

| VM20-4ML | – | ||

| VM20-5ML | – | ||

| VM20-6ML | – | ||

| VM20-7ML | – | ||

| VM20-8ML | – | ||

| VM20-10ML | – | ||

| VM20-12ML | – | ||

| VM20-14ML | – | ||

| VM20-17ML | – | ||

| VM32-2AML | – | DN65 PN25 | 2 1/2″ BSP(F) |

| VM32-3ML | – | ||

| VM32-4ML | – | ||

| VM32-5ML | – | ||

| VM32-6ML | – | ||

| VM32-8ML | – | ||

| VM32-10ML | – | ||

| VM32-12ML | – | ||

| VM42-1ML | – | DN80 PN25 | 3″ BSP(F) |

| VM42-2ML | – | ||

| VM42-3ML | – | ||

| VM42-4ML | – | ||

| VM42-5ML | – | ||

| VM42-6ML | – | ||

| VM42-7ML | – | ||

| VM42-8ML | – | ||

| VM42-9ML | – | ||

| VM42-10ML | – | ||

| VM65-2AML | – | DN100 PN25 | 4″ BSP(F) |

| VM65-2ML | – | ||

| VM65-3AML | – | ||

| VM65-4BML | – | ||

| VM65-4ML | – | ||

| VM65-5AML | – | ||

| VM65-6BML | – | ||

| VM90-3ML | – | DN100 PN25 | 4″ BSP(F) |

| VM90-4ML | – | ||

| VM90-5ML | – |

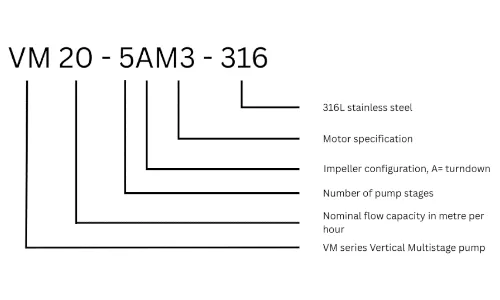

Decoding the Vertical Multistage pump structure

Understanding a pump’s code is essential for installation, maintenance, and reordering. The VM series uses a logical identification system that makes this easy:

- An acronym for Vertical Multistage stainless-steel pump.

- Nominal capacity at best efficiency points in metres per hour.

- The number of stages indicates pressure capability.

- Motor types represent M3 for three-phase and blank for single-phase.

- The number 316 describes stainless-steel hydraulic parts built from AISI316L.

For example, VM20-5M3-316 is a vertical multistage water pump with 20 best efficiency points, a five-stage design, a three-phase motor, and AISI316L wetted parts.

This coding symbol ensures consultants can easily specify the right pump, installers can simplify installation, and operators can reorder confidently without corrosion.

System components and accessories

The Davey VM Vertical Multistage water pump is more than an ordinary pump; it is an engineered solution, carefully designed with durable components and flexible accessories.

At its heart lies a proven Vertical Multistage centrifugal pump design, while a suite of system add-ons ensures adaptability in every industrial, commercial, or domestic context.

Pressure switch for built-in intelligence

Every VM electropump is fitted with a TEFC motor, ensuring dust, moisture, and contaminants stay outside the housing.

This protection safeguards the shaft and impeller, critical parts for long-term operation in industrial environments.

The TEFC construction provides quiet, efficient running, excellent cooling, and extended lifespan, which are vital qualities for both booster pump and pressure pump applications.

Pressure tank to smoothen flow and reduce strain

Optional pressure tanks store a reserve of water under pressure, allowing the VM Vertical Multistage water pump to deliver smooth and uninterrupted flow.

This reduces on/off motor cycling, prolongs the life of the mechanical seal and shaft, and ensures steady output across showers, taps, and irrigation systems.

Mounting skid systems

Davey offers complete skid-mounted packages for larger-scale booster pump applications that integrate multiple VM pumps into one system.

These industrial assemblies arrive pre-piped and pre-wired, saving valuable time during installation.

Built with corrosion-resistant stainless-steel parts and precise alignments of each electropump, the skid system guarantees consistent pressure delivery, a reduced footprint, and easier servicing.

RainBank

Davey’s intelligent rainwater harvesting system integrates with the VM Vertical Multistage water pump to automatically select between rainwater and mains supply.

This makes the VM series ideal for commercial buildings, apartments, and industrial facilities seeking sustainable water management without compromising pressure or flow.

Certified pump compliance

Every VM Vertical Multistage water pump complies with rigorous international testing. This certification reinforces the product’s safety and reliability:

- ISO 9906:2012: Defines hydraulic performance acceptance tests for rotodynamic pumps, confirming each VM Vertical Multistep centrifugal pump meets strict efficiency and flow standards.

This approval matters not just as compliance tick but as reassurance for consultants, installers, and end-users. When you see these certification symbols on a Davey product, you know it has been independently tested and trusted to deliver.

Totally enclosed fan-cooled (TEFC) motor as the core of reliability

Every VM electropump is fitted with a TEFC motor, ensuring dust, moisture, and contaminants stay outside the housing.

This protection safeguards the shaft and impeller, critical parts for long-term operation in industrial environments.

The TEFC construction provides quiet, efficient running, excellent cooling, and extended lifespan, which are vital qualities for both booster pump and pressure pump applications.

Varied inlet sizing for flexible connection

The inlet of each Davey VM Vertical Multistage water pump is designed with variable sizing across models, ensuring compatibility with diverse systems.

Each version of this centrifugal pump can be custom-fitted using specialized connectors, simplifying installation in residential, commercial, or industrial booster applications.

Constructed from durable stainless steel, the inlet is corrosion-resistant and engineered for long service life.

The inlet design incorporates Net Positive Suction Head (NPSH) considerations, ensuring sufficient suction pressure to minimize cavitation and maintain stable hydraulic performance.

Water flows smoothly into the inlet, directed towards the impeller and shaft, where pressurization begins within the electropump. This adaptability guarantees efficient unidirectional flow and consistent operation across the booster and pressure pumps.

Stainless steel volute casing for protection and hydraulic efficiency

The Davey VM Vertical Multistage water pump’s volute casing provides housing strength and hydraulic efficiency.

Constructed entirely from high-grade stainless steel, it aligns the shaft, impeller, and mechanical seal in perfect orientation for maximum reliability. Designed in a spiral form, the volute channels water from the impeller, converting velocity into pressure as it moves toward the outlet of the vertical centrifugal pump.

This casing enhances flow consistency, reduces vibration, and protects critical parts of the electropump from debris. The volute casing is ideal for skid-mounted systems and industrial booster setups, ensuring performance, safety, and durability.

Included In The Box

VM Vertical Multistage water pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us