Davey Malaysia / Home / Water Pump / Davey Vortex Sump Pump

Davey's Vortex sump pump

Key features:

- Sump pump type.

- Suitable for factory and sewage removal.

- For sump emptying, septic effluent disposal, water transfer or pumping of light slurries.

- 12 months warranty for pump, motor & float switch.

- Hermetic seal for watertight closure.

Overview of Davey's Vortex sump pump

It takes more than just a pump to solve everyday drainage challenges; you need a dependable, durable companion that can work even under the most challenging conditions. The Vortex sump pump by Davey, also known as a submersible grey water pump, achieves reliability through innovative design and robust materials. Whether it is emptying a basement, managing a stormwater pit, or transporting grey water from a catch basin below a residential foundation, this pump is designed to make water work more efficiently.

Every Davey drainage pump is built with a balance between robust engineering and user-friendliness. Sand slingers and corrosion-resistant 304 stainless steel motor shells, fasteners, and strainers are included with every model to protect against extreme groundwater conditions, moisture, and oil. The whirlpool effect produced by the centrifugal vortex impeller allows soft solids to pass easily without clogging. It is a proven design that provides outstanding performance where dependability, efficiency, and extended service life are most important in basements, plumbing systems, building sites, and marine installations.

Built for use in grey water, septic effluent, or light slurry applications, the Davey vortex sump pump provides smooth performance in underground pits, storm drains, or concrete sumps. It is a reliable option for both residential and commercial water management, where dependable submersible pumps are crucial to keeping spaces dry and protected. Its performance and safety have been honed over decades of experience.

Range overview and performance options

Each application has its own performance requirements. The Davey vortex sump pump range includes models that handle a variety of drainage and wastewater challenges, from residential sump drainage to industrial transfer systems.

| Model No. | Motor Output, kW | Rail Kit | Voltage | Outlet | Product Group |

| D15VA | 0.15 | N/A | 220/240 | 1¼″ | 1051 |

| D15VAGMA | 0.15 | N/A | 220/240 | 1¼″ | |

| D25VA | 0.25 | N/A | 220/240 | 1½″ | |

| D40VA | 0.40 | N/A | 220/240 | 2″ | |

| D75VA | 0.75 | N/A | 220/240 | 3″ | 2010 |

| D150V | 1.50 | SR80 | 220/240 | 3″ | |

| DT08V | 0.75 | N/A | 415 | 3″ | |

| DT15V | 1.50 | SR80 | 415 | 3″ | |

| DT37V | 3.70 | SR80 | 415 | 3″ | |

| DT75V | 7.50 | SR100 | 415 | 4″ |

Compact models, such as the D15VA, D15VAGMA, D25VA, and D40VA, are ideal for light commercial or domestic use, including garden systems, basement pits, and grey water disposal. They handle soft solids up to 20 mm (D15VA/D15VAGMA), 25 mm (D25VA), and 35 mm (D40VA), with flows of up to 240 litres/min and heads of up to 7.5 m. Their lightweight design and optional vertical float switch make them easy to install and maintain.

The D75VA and DT08V handle soft solids up to 46 mm, offering flows of up to 600 lpm and heads of up to 8.5 m. With cast iron impellers, double mechanical seals, and an oil bath design, they deliver reliable service in construction drainage, foundation pits, and light slurry applications.

At the top end, the D150V, DT15V, DT37V, and DT75V offer outputs ranging from 1.5 kW to 7.5 kW, capable of handling fluids containing small soft solids or light suspended particles. Designed for storm drains, mining, and marine sump installations, they can be paired with slide rail kits (SR80/SR100) for safe and simple pump retrieval in deep and confined areas.

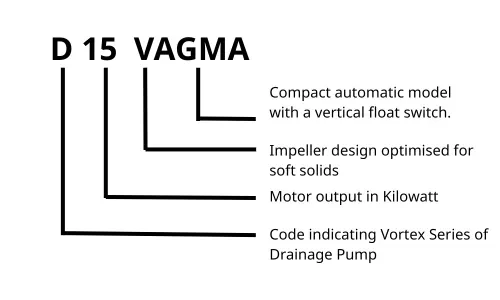

Vortex sump pump identification

Selecting the proper submersible sewage or drainage pump is simplified with Davey’s clear model identification system.

Each model name conveys specific performance and configuration information, helping installers and engineers quickly identify the right fit for any water pump system.

- Prefix “D” or “DT” – Indicates a Davey vortex drainage pump, with “DT” denoting a three-phase electric motor.

- The following numbers represent the approximate motor output in kilowatts, indicating the pump’s power and pressure capacity.

- Suffix “V” – Identifies the vortex impeller design, optimised for pumping soft solids and grey water with reduced risk of clogging.

- Suffix “A” – Denotes an automatic model equipped with a standard float switch, which activates the pump based on the water level.

- Suffix “AGMA” – Refers to compact automatic models fitted with a vertical float switch. This internal float design is ideal for narrow sumps or confined pits, where space is limited and a traditional tethered float cannot move freely.

Thus, the D75VA is a 0.75 kW single-phase vortex pump, excellent for household sump drainage or wastewater transmission. Meanwhile, the DT37V is a 3.7 kW, three-phase pump designed for industrial wastewater pits or stormwater systems that require higher capacity and pressure.

Attachments

HO7RN-F oil-resistant power cable

Safety and reliability extend to the power supply. Each pump is equipped with a 10-metre HO7RN-F oil-resistant power cable, designed to withstand exposure to moisture, oil, and chemicals commonly found in basement pits, marine sumps, and industrial wastewater systems.

In addition to preventing abrasion and fatigue during installation or maintenance, the heavy-duty rubber insulation guarantees flexibility even in cold temperatures.

The three-phase units have bare wire leads for simple connection to control panels, whereas the smaller models come with a moulded AU plug. This cable design ensures steady electrical performance in wet environments, providing the pump’s submersible motor with consistent and safe power delivery, a crucial feature for continuous water transfer, drainage, and wastewater pumping tasks.

Sand slinger lip seal

A small yet vital component of every Davey submersible pump is the sand slinger lip seal, which prevents abrasive particles from entering the motor chamber. It serves as a barrier between the impeller housing and the mechanical seals, shielding internal parts from silt, grit, and fine debris that are frequently found in storm drains or grey water systems.

This additional protection prolongs the life of the motor bearings and seals in underground installations or construction pits, guaranteeing smooth performance and thereby reducing the need for frequent maintenance. The Davey centrifugal submersible pump is a reliable option for long-term drainage and groundwater management due to its double-seal system and multi-layered protection against wear provided by the sand slinger.

Float switch (compatible for automatic control)

The Davey vortex sump pump line includes automatic water level management. The “A” suffix models have a tethered float switch that stops the pump at a safe low level and turns it on when water rises. Compact models with the suffix “AGMA” feature a vertical float switch, making them ideal for small pits with limited space. By preventing dry running, these devices lessen impeller and motor wear.

This automation ensures that the submersible drainage pump runs only when needed, conserving energy and prolonging the lifespan of stormwater pits, septic tanks, or foundation sump pumps.

Slide rail kits for easy and safe installation

Davey slide rail kits are purpose-designed to simplify the installation and removal of submersible pumps from pits, basins, or tanks. They enable maintenance teams to easily lift the pump out without unbolting the pipework or entering the pit, ensuring safer and faster servicing. Available in 50 mm, 80 mm, and 100 mm nominal bore sizes, these kits are designed to suit specific vortex sump and sewage pump models, typically those that are heavier or installed in areas where frequent cleaning or inspection is required.

Constructed in both standard and 316 stainless steel for superior corrosion resistance, the range includes the SR50, SR80, SR100, and SR150 models, with stainless steel options available as SR50SS, SR80SS, and SR100SS. Each kit provides a secure and reliable mounting system that enhances serviceability and extends pump life.

| Part No. | Rail Size (Nominal Bore -Rails not Included) | Suits | Outlet |

| SR50 | 1″ | Grinder & 2″ Sewage | 1¼″ or 2″ |

| SR80 | 1¼ ″ | 3″ Sewage | 3″ |

| SR100 | 1½″ | 4″ Sewage | 4″ |

| SR150 | 1½″ | 6″ Sewage | 6″ |

| 316 Stainless Steel Models | |||

| SR50SS | 1″ | Grinder & 2″ Sewage | 2″ |

| SR80SS | 1¼″ | 3″ Sewage | 3″ |

| SR100SS | 1½″ | 4″ Sewage | 4″ |

Certification

Every Davey Vortex sump pump is engineered and manufactured to meet strict international standards for safety, quality, and environmental performance. Built for durability in demanding drainage and wastewater conditions, each unit undergoes rigorous testing and certification to ensure long-term reliability and user safety. The following certifications and inspections apply to this product range:

European Conformity (CE): Demonstrates full compliance with the European Union’s directives for electrical safety, health, and environmental protection. This certification confirms that every Davey Vortex sump pump has been tested for safe electrical performance, structural integrity, and compatibility with environmental standards.

Geprüfte Sicherheit, GS (TÜV022849EA): Certifies that Davey Vortex sump pumps have successfully passed independent testing conducted by TÜV under the German Product Safety Law (ProdSG). The GS mark confirms verified mechanical and electrical safety, assuring dependable, long-term performance in critical drainage applications.

Electromagnetic Compatibility (EMC) Compliance: Demonstrates conformity with the Australian Communications and Media Authority (ACMA). This certification ensures the pump neither causes nor is affected by electromagnetic interference, allowing reliable operation alongside other electrical devices.

Standards Australia: Confirms that the Davey Vortex sump pump meets the national benchmarks for product safety, performance, and material quality as established by Standards Australia.

- AS4020 Sub-Clause: Tested in accordance with AS4020 to confirm suitability for contact with drinking water. This ensures no harmful substances leach from the pump’s construction materials, maintaining water safety and compliance with Australian health regulations.

New Zealand Standards: Demonstrates adherence to New Zealand’s regulatory framework for electrical and water-handling products, ensuring safe and reliable operation across domestic and commercial systems.

- NZS4020 Sub-Clause: Equivalent to Australia’s AS4020, this standard confirms that the pump’s materials are safe for potable water contact. It validates both environmental and health safety, ensuring dependable performance in New Zealand’s water management applications.

Sump pump selection guide

This sump pump selection guide helps match pump types to fluid conditions.

From rainwater and clean drainage to grey water, wastewater, and heavy slurries, each pump model is designed for specific particle sizes and contamination levels. It ensures users select the most efficient and durable pump for their drainage or wastewater application.

| Suitable Fluid | Rainwater | Drainage | Dirty Water / Greywater | Wastewater / Effluent / Sewage | Sludge / Slurries | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pumps | D23A/B, D42A/B & D53A/B | Small Double Case Submersible Water Pump Models (DC10) | Small Dewatering Pump Models (D10 & D15) | Double Case Models (DCS40 & Above) | Dewatering Pump Models (D25 & Larger) | Single Channel Models (S) | Vortex Models (V) | Cutter Models (K) | Grinder Models (G) | Sludge & Slurry Models (KZN) |

| Fluids / Application | ||||||||||

| Fountains | X | ✔ | — | |||||||

| Rainwater (e.g. tank to garden or home) | ✔ | — | ✔ | — | ||||||

| Stormwater and surface run off water | ✔ | X | ✔ | |||||||

| Greywater with nil or few soft solids (e.g. septic tank pump-outs) | ✔ | X | ✔ | |||||||

| Dirty water with less than 1% small hand solids – some wear can be expected (e.g. site dewatering, swimming pool drainage, stormwater pumping) | ✔ | X | ✔ | X | ✔ | |||||

| Water with up to 10% soft solids in suspension – max. particle size is 80% of pump outlet (e.g. semi screened raw sewage, stock effluent, grease traps) | X | ✔ | ||||||||

| Water with medium volumes of hair in suspension (e.g. greywater, abattoir wash down, dog washing, animal washing) | X | ✔ | X | |||||||

| Water with stringy materials in suspension (e.g. laundromats, cotton & wool mills, food factories) | X | ✔ | X | |||||||

| Raw sewage including sanitary products | X | ✔ | X | |||||||

| Slurries with up to 35mm particles in suspension up to 70% by weight (e.g. sand and slurries, building site water, mine site water) | X | ✔ | ||||||||

Corrosion-resistant 304 stainless steel construction

Material selection is the first step towards durability. Every vortex sump pump’s motor shell, shaft, handle, and fasteners are composed of 304 stainless steel, which provides exceptional corrosion resistance even in underground, marine, or oil-contaminated environments. This robust design ensures long service life and continued performance, even in harsh environments such as concrete pits, foundation drains, or fuel catch basins.

In addition to maintaining the structural integrity of the pump, the stainless-steel parts offer a clean, appealing surface that is impervious to wear and corrosion. Whether installed in a residential sump or a commercial wastewater system, this corrosion-resistant build ensures each electric motor pump remains reliable year after year, even under continuous submersion.

Specialised impeller design for efficient flow

The open or semi-vortex centrifugal impeller, the core of every Davey vortex sump pump, is designed to transport water and soft solids effortlessly. The vortex design, in contrast to traditional impellers, produces a whirlpool motion that keeps material suspended and avoids clogging at the impeller’s eye. Constructed from polycarbonate in the smaller pumps and cast iron in the larger models, it resists wear while maintaining consistent performance.

This design is particularly effective for grey water, drainage, or light slurry applications where fibrous matter or sediment is present. The result is a robust centrifugal water pump capable of continuous operation in basement pits, storm drains, and construction sites with minimal maintenance.

Double mechanical shaft seals in an oil bath

To ensure long motor life and protection against leakage, the medium and large-sized Davey vortex pumps feature double mechanical shaft seals (smaller models have single seals) housed within a lubricating oil bath. The pump-side seal is made from silicon carbide and ceramic, while the motor-side seal uses carbon and ceramic, providing a strong defence against wear and ingress of water or grit. The oil bath reduces friction and disperses heat, keeping the electric motor cool during prolonged operation.

This system is crucial for reliability in basement drainage, construction dewatering, and industrial waste applications where continuous operation is standard. The result is enhanced hydraulic performance, extended service intervals, and assurance that the pump can withstand demanding, high-duty environments.

Included In The Box

Vortex Sump Pump

User Manual

Proof of Purchase

12 Months of Manufacturer Warranty

Contact Us