Davey Malaysia / Home / Water Pump

Water Pump Sub-Categories

Water Pump In Grouped Product View

Davey’s mother of all water pump categories is here, featuring all the pressure systems in our current Asian catalogue.

Household Pump

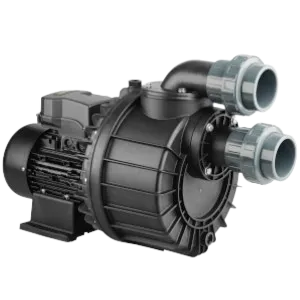

Swimming Pool Pump

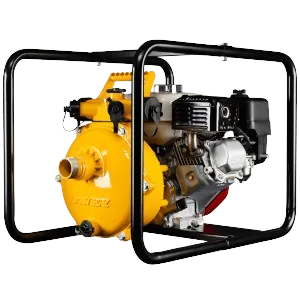

Engine Water Pump

Gusher And Effluent Pump

Shallow Well Pump

Deep Well Pump

Water Transfer Pump

Horizontal Multistage Water Pump

Borehole Pump

Sump Pump

Circulator Pump

Vertical Multistage Water Pump

End Suction Pump

Pump Set

Language Setting

Water Pump by Davey

Davey Malaysia is now featuring the mother of all water pump categories right here. Though may it be known with a variance of many names—from electropump, booster pump, hydraulic ram, diesel/gasoline pump, water system, and even centrifugal pump, we’re elated to be using the generic and widely known calling, categorising our water pumps according to its assortment in order to serve anyone across any levels of the supply chain better. This is seen and met with a vocational of interests found, as we arrange our pump types following the demographics of uses available – which Davey Water Products Pty Ltd (our headquarters) have initially devised right off the bat to cater to specific needs, showing changes across technology and mechanical engineering prowess.

Pump History

Believe it or not, water pumps have been available for days of the past where time immemorial. Stretching back into the roots of the 17th century, centrifugal pumps was pioneered in the beginning just years after proving the theory of centrifugal force by mathematician and physicist Christiaan Huygens. Built further into understanding the laws of motion, Isaac Newton discovered that with every actionable force of movement, there lies an equal or opposite force, leading to the development of a primordial pump creation. Straight vanes were the initial design by Denis Papin, and this was during the absence of electricity, and the first water pump in the making was manually turned as a person would have to move the wheel (or crank) in order to create the rotational energy needed. Slight alterations were set into application, and during the mid 1800s, John Appold formalise the usage of curved vanes that drew about significant changes in the centrifugal pump’s efficiency. This became maintained onward and into the present, whether as a de facto benchmark or plain presumption of vane curvature into every pump use, the advancement behind proficiency to drive even more water flow has been catalysed and focused after.

By the start of industrialisation, the increasing expansion of current and circuitry have pivoted a change towards water pump machinery, and this time, to implement the mechanisation in order to drive the centrifugal pump automatically. This is to keep up with the world’s rapid change then, and with the help of galvanism, the birth of electrical water pump (or electropump) is now born, marking the start of the ease of pressurisation without manual labouring. Although the exact date of when electric pumps began remains unknown, Davey Malaysia is elated to announce that every water pump being produced remains a stable and mature invention fundamentally that has not change to-date.

Yet far into the outskirts of mainstream voltaic use, the unconventional diesel-based engine of water pumps was ployed into tremendous in-field practice by Davey. This was brought in to cater to markets where jolts of power is deemed unavailable or difficult to obtain, requiring the usage of fossil fuel to run the pump.

Specific Water Pump Branching

Our electropumps came from the many moments of epiphany by Davey’s engineers, and this was through visualising problems to rectify, to real-life inspiration or even through high-tech go-forward where these water pumps were introduced. And the unique scores of years in assembling and supplying have led Davey into specialisation across various sort, and each to its own features and characteristics that remains suitable to the scenarios of water pump application. Today, Davey Malaysia have the coverage of virtually any fields with the right centrifugal pumps, but this was always debated upon the collective. Whenever the branching of pump idea brews, the engineers come together for a discussion to see if the projected vision is permissible. The peer review by Davey’s engineers and administration was a mandated necessity to ensure that any of the water pump being developed could be marketed and used, and that the surveying of a proper market share for the very stated niche can be readily seen across a region (or the world).

When the discussion ends, problem statements are sampled and scoured across the field to determine the solution that is built into Davey’s water pumps. A slow but ample amount of time is allocated to quantify as much trouble a trade would face that can be rectified eventually, and as you know it, measures are then taken from research into development, most often are materials science and body structure addition or alterations that are conducted onto the centrifugal pump. Yet creating a niche-specific water pump is one thing, but scaling into industrial-wide production is another. As manufacturing involves automating steps meticulously, the overall costing-meet-designated-function plays a pivotal role for the creation of any water pumps as the gadget becomes used across the distribution chain. In here, most often it is the tried-and-true innovation and physical property discovered that are applied into electropump and its fossil fuel iteration building. This is to lessen expenditure from unnecessary research, and where efficiency of use meets justifiable pricing, the byproduct of all these are the mentioned specific water pumps that are branched out.

Household Water Pump

One of the available assortment centred to electropumps is the home-usage variant. By market insight, water pumps that are specialised into the category of household use has the most market capitalisation. This is because it would be singularised onto individual residential use, and statistical study from Malaysia Property Market Centre (NAPIC) shows that the backwater nation currently holds 6.3 million units of housing properties as of 2023, which would fit the same number of water pumps equally (or more). As some private family homes are in multiple storeys, larger buildings would require a stronger centrifugal pump, or multiple sets of it to fulfill the high pressure environment, whereas smaller family homes would equally require a smaller pump in their stead. Affordable budget is priced according to the economics of household scale, where small-sized pumps can cater for miniature residences and is far cheaper, while larger nestings are premium in range.

All water pump for house are built to the vicinity of the home, which can include basic irrigation across your garden, bathing, washing the dishes and showering use, and even to the extension of swimming pool. Throughout the world, every single authorised retailer and distributor would recognise our line of house pumps as the ‘Home Pressure System‘ in inventory. Yet, the distinctive factors that pivots the water pump for household tends to steer a focus of lower noise (weighed by Decibels), and also lesser voltage consumption by being energy-efficient. Quiet operation that results in lesser decibel rating could be a combination of factors, which can be configured to a boon through volute cover changes, lubricant upon nuts and bolts fitting, as well as material usage. On the other hand, electrical efficiency is achieved typically by using the appropriate speed for the right usage. A variable-frequency drive (VFD), or a variable speed booster, is attached onto a centrifugal pump, and depending on the intensity of use, the motor would run faster or slower. 1 HP or 1.5 HP (horsepower) is pretty much an old way of gauging, but also common standing of the performance of housing pumps.

Garden Pump

As a spinoff and a more thorough specialisation from the branch of housing pumps, the water pump for garden is derived to hose down blossoming shoots of plants and shrubs. The differentiation as a micro-branching of housing pumps is that this lawn-based forte is smaller in size, because a mini engine is a just-nice fit for a splash. With droplets that hydrates as gently as possible, the water pump’s soft dampening do not cut the thin stems that damages growth. All garden pumps adhere towards the standard of environmentalism, where greenhouse emission is reduced with the miniature engine that consumes even faint voltages. Up to 0.5 HP can be achieved with the smallest garden pump, and besides that, a rainwater harvesting system can be installed where collected rain as an alternative water supply is used. This helps the Malaysian to save up even more on utility bill, while learning to utilize natural means to fulfill the same water pump mission.

High Head Pump

Contrary to landed properties, the high head pump is built solely to push pressure upwardly, or in a vertical manner. This series of water pumps are only situated within high-rise buildings; offices, apartments, and/or condos alike would find electropumps like this essential for living quarters and occupied working space. For such a water pump are generally large in measure, the TEFC motor (or totally enclosed, fan-cooled engine) must be high-powered to fulfill the required pressurisation. When you’re seeing the performance curve, one would find that the QH value of high head pumps would still rise steadily as the distance in meters go further. High head pumps are generally installed at the basement of the tall buildings, or in a section where the public finds it inaccessible.

Mini Water Pump

Mini pumps can be defined by its rather tiny stature of creating pressure, and motor like this can consume for as low as 12V and may be powered by a battery. The mini water pump assortment of products can be used for fish pond, to hydroponics, and even acting as a small water feature.

Diesel Fuel Pump

Considered the most portable form of engine water pumps in the current market globally, the diesel fuel pump, as the name suggests, runs on a fossil energy that converts into mechanical energy and further into pressure after the initial combustion. As was mentioned earlier, Davey’s diesel pumps can be carried across any plains and areas where limited access to current is prominent. This is used to fend against open burning and/or wildfire as part of the equipment among firefighters, where combat against illegal deforestation is done so. With a fuel tank that can be refilled at any time of the day, all petroleum and diesel pumps can continue to carry out distant soaking and spraying without fail.

Gasoline Water Pump

Another form of the hydrocarbon engine pump. The popularity of petrol variants are created to cater to markets that primarily uses gasoline as the main combustible source, and this is then carried forward into water pump creation. Depending on the order, Honda engine or others can be fastened. Typically, the gasoline water pump remains one of the most popular choices of a centrifugal pump when it comes to anywhere firefighting. No different than the diesel fuel pump, the gasoline type can be replenished anywhere as long as a reserve of petrol remains available.

Aquarium Pump

The water pump for fish pond or aquarium can also be included as part of the housing catalogue, as well as another miniature iteration of the submersible pump. Since this form of machinery is designed to be placed completely underwater, the aquarium pump can be considered as zero prime just as it is needs not to suck any water in from the inlet. Instead, liquids would consistently flow in on its own. Davey’s DynaPond is one such version of the aquarium pump that has a filter cartridge which traps waste away, cleaning and sending out clear hydration after. The water pump for aquarium is also crucial to encourage the exchange of aeration, nutrient and oxygen circulation to ensure a healthy artificial marine habitat. Most, if not, all aquarium pumps are made to be small-in-size. In Davey’s Garden System model, the pump can be joined into a sprinkler for a drip irrigation methodology.

Submersible Pump

One of the water pump variations consisting of a huge market capitalisation chunk, the submersible pump is also part of the alignment sorting found with Davey. This ranges from fountain use, to aquaculture, freshwater and even saltwater implementation. For deep sea use, centrifugal pumps tend to be made in titanium to resist against saline corrosion.

Slurry Pump

Slurries are a mixture of solid particles in a fluid state, and the concoction remains viscous in nature that drags along the pipelines to create movement resistance where the average pump will find it hard to pressurise. As such, the particular uniqueness of slurry pumps are used, and this is equivalent to an industrial-scale of a water pump, large in dimensions, which is needed to push volumes of pasty liquids out.

Sewage Pump

Sewage pumps are a form of commercialised heavy-duty pump that are inherently built to move wastewater in the sewer line. A cutter may be attached internally just after the suction inlet, and this is deployed to chop up hard solids, toilet papers, and even flushable cleaning products where this water pump version is often used across wastewater treatment facilities and also water reclamation plants.

Water Jet Pump

One notable variant features the utilisation of a Venturi tube that replicates the Bernoulli’s Principle in a water pump. The Venturi effect states that fluid velocity increases as pressure decreases, and this is achieved by having a narrow cone segment in the tube. Because of the rampant fluid velocity that shoots out, the discharge makes the machine known as a water jet pump.

Water jet pumps are used in various fields and applications today. For example, the bubbles found on a jacuzzi are a mixture of air that’s made with a water jet pump for a luxuriant feel. High pressure washer required to clear off stuck grime or dirt in the kitchen or the car is also the result of using a water jet pump. In Davey, a few models are made to be jet in variation, and these are suffice for a smaller home use for the needed pressure.

Automatic

For all electropumps, these mechanisms are constantly plugged into the wall socket to be active at all times for usage, which goes the name of it being an automatic water pump. Whenever a faucet becomes opened, water is released from the pipeline, which causes a drop in pressure levels found. This is monitored by all water pumps as a basic working principle to start on its own.

Efficient: The built-in control panel that detects hydrating levels in Davey’s water pumps will consume very little voltages. When no shower heads nor taps are used, the centrifugal pump stays idle and will not consume additional Galvanic charges other than the detection.

Labour-Free: Unlike age-old centrifugal water pumps, manpower is no longer needed for consistent monitoring and to turn manually. Instead, the machinery would start its operation once the pressure drop happen.

Consistent: It’s important to know that automatic water pumps would flow continuously on end in the cycle of its system. This is also important as to inhibit water hammer from occuring that can damage the internal pieces. As such, the reliable performance must be maintained for every water pumps out there.

Body Construction

The bodywork for every h2o pump is considered with thoughtful conscience in mind:

Ergonomics: Whenever favourable towards relocating the machine, Davey’s water pumps has been built to be ergonomical so grip is enhanced upon transportation. Sections of the construct is knurled-in, with slanting gaps or handle to carry easily, and this is primarily observed with Davey’s firefighting pumps. Essential to move anywhere, first responders, emergency rescuers and/or fire men and women would find the skid frame a convenient place to hold, and the water pumps are migrated accordingly whenever crisis like bushfire disaster have subsided to gush down another area of on-going incineration.

Lightweight: Under the consensus of portability, all residential (household and garden) centrifugal pumps, submersible, agriculture, aquarium, construction, and also fossil fuel, petrol, and/or gasoline water pumps are generally light in mass. With heavy duty pumps (also defined as commercial in terminology) being an exception, the minimal weight makes the contraption all the more easier to be carried around.

Stainless Steel

In many individual parts, including the body construction, centred to Davey’s centrifugal water pump, are components mainly made out of robust stainless steel in property. The alloy application features a number of uses that has various crucial role in both maintaining and using the water pump:

Drives Directional Flow: As hydration is drawn in from your water tank through the suction inlet, clean liquids are flown unidirectionally to the discharge outlet because of the rigid structure by the water pump’s schematic that is installed into place.

Debris Protection: External moisture, dust particle, and/or outside debris will be blocked due to the metallic package that is covering the water flow, as well as the components of the water booster pump, ensuring that no impending damages are done and clean hydration are always supplied.

Rust-resistant: The composite metal of stainless steel becomes chosen as a de facto of standard, and the reason is its anti-oxidation purpose that helps to sustain usage for the long-haul. In addition, leeching rust into the water supply is detrimental to anyone’s health, making the alloy as a go-to with Davey Malaysia as a centrifugal pump supplier.

Inert: One of the biggest reasons behind applying stainless steel as the property medium in the pumps of Malaysia is its non-reactivity with clean water.

Strong: The metal composite remains a very durable water pump housing where foreign blows can only make a dent, further emphasising on the defense of the parts within.

Thermoplastic Casing & Bits

While most of Davey’s water pumps across any category are made by the benchmark of alloy metal, a few water pumps are built by using thermoplastic as a core component for both its casing as well as the pieces internally. The carbon-based chemistry comes to application as it fulfills the function no different than robust stainless steel, with the exception of it being used under special circumstances across water pumps in Malaysia.

Low-Cost: The plastic employment for certain parts aid to reduce any water pump’s assembling expenses, just as polymer can be made within industrial-scale factories with plain carbon alone, water, as well as with the right pressure, than having ores dug out from the mine, shipped out, and processed with heat to be pure metal and then refined further into composite alloy.

Stable: The plastic injection moulding of impellers (regardless if it’s single phase or multiple), and also any parts surrounding it (volute cover, diffuser, or others) remains chemically stable and will not react to clean water sourced by your state provider (SYABAS Air Selangor, SAMB Melaka, Ranhill SAJ, etc), which is suffice to say that thermoplastic usage is as good as metallic components in a centrifugal pump.

Pressurise Corrosive Liquids: In cases when sludge or slurry fluids are being pumped, during such instances the liquids can be acidic or extremely alkaline in nature, yet either ways in pH value, the flowing substance can be corrosive in nature. This reacts to the conventional alloy, which are often advised against using for eroding liquids, and where thermoplastic water pump parts shine due to its chemically inert nature.

Reduced Bearing Stress: Polymer-based impeller and parts, in general, are less heavy in contrast to their metal counterparts, which reduces bearing stress overall in a water pump, while ensuring long-term durability.

Non-Conductive: Plastic applications will never conduct electricity, which is why most, if not, all water pump’s gasket and even the backplate are made with polypropylene (PP) thermoplastic. It ensures that electricity generated from the motor engine will not be transferred onto the water pressure, ensuring safer irrigation, domestic or commercial use with all of Davey Malaysia’s centrifugal pump.

Easily Replaceable: Polymer moulding is far easier to get, in order to replace an existing part that’s damaged through wear and tear in a pump operation.

Water Pump's Price Value

The great benefit centred to Davey Malaysia being a water pump manufacturer and supplier is that raw materials are directly sourced for the rest of our merchandises to be produced internally within our facilities. This is added with the agreement of buying supplies in large bulks for the batch creation of centrifugal pumps. When these combination are done so, the pricing for all of Davey’s water pumps are driven low and into fair value bargain across the supply chain, ultimately benefiting end consumers.

Davey Water Products Pty Ltd and all of its entities have always sought to benefit the end users as much as possible with the usage of our water pumps, and this is without compromising on quality and neither are we leaned towards capitalism. This principle has been multigenerational and has stretched for days of the past since Davey’s centrifugal pump founding times. With humanitarianism in mind and precept, it must be stated that our water pump’s price value will always cater to everyone, and never a luxury asset.

Other Field of Pump Interest

Almost every sector is in the coverage of water pumps’ usages – so long pressure is needed in the field applied. As such, Davey’s expansion towards other fields of interest that are (outside of residential compounds) have allowed us to have a hold a brand presence as we facilitate solutions needed. The following industries are some that are widely using electropumps and diesel-pumps in Malaysia:

Construction Site

In developing places where premises are being built, centrifugal pumps becomes a necessity for dewatering objectives because as digging happens, water tables can be uncovered and this causes the structural integrity to be destabilised, as well as creating an unsafe work environment. In cases like this, a high-powered sump pump is needed to completely remove excess water just so the project can be resumed and to ensure a balanced floor plan.

Regulating Rainfall Flood: Under rainy seasons or heavy downpour, the muddy and sandy fields of low-lying areas of the construction site may be submerged under floods, which also mandates the transfer pump to redirect trapped water out. One of the major reasons centred to this comes is that floods actually do damage industrial machineries (like a generator set, or tractors), which is also important for people to deploy a water pump to preparation in case of a contingency.

Concrete Pouring: Prior to layering with concrete, the very same area of excessive dampening must be removed with a water pump to safeguard oneself for a better curing, otherwise the dilution would leak to a weaker mix.

Industrial Manufacturing

Electropumps are still needed across every factory found – whether industrialised or not, to force hydration out. This may not be centered towards production line that is water-reliant, yet for bathroom reasons, to washing the dishes in the pantry, or even your hands and minor flowery plants splashing, a water pump is still necessary for even the most basic of use.

Pump In Textile Manufacturing

In commercial processing, large bodies of water are required to be moved, so the volume can only be necessitated by industrial water pumps. This is commonly seen in broad-scale fabric making, with a final texture obtained when washing, softening, and others are done so, yet all the more requiring of both water and also centrifugal pump in-use.

To begin with: hydration may first be injected into the water tanks for storage purposes and is then used into in the dyeing facility, as well as every other mandatory spaces. Water pumps play two major roles here:

High-Flow: The pressurisation offered by electropumps are needed to enforce proper fabric treatment in textile units.

Circulation: As colourising becomes in-place, the next pit-stop that water pumps are used for, is to remove excess stain, as well as excess impurities left within the soaking (and also the cloth).

Water Pumps As Machinery Coolant

Depending on the mass producing plant, such as steam dyeing, or even metallic wielding, there are contraptions that would generate a significant amount of heat during the development processing, and during this particular instance, a water pump is applied to swirl away hotness in cooling towers in order to prevent overheating.

This is possible as the dampening absorbs thermal energy in the form of heat transfer, and the water pump moves it to the cooling system to relief its boiling temperatures, right before returning back to the structure as a cycle once again. Maintaining coolness with industrial water pumps remain extremely crucial to prevent impending damage while emphasising on safety issues.

Pumps For Wastewater & Recycling

The wastage byproducts left within the water after the manufacturing assembly is often harmful, yet it remains a necessity to be pumped out centrifugally to manage, recycled for greater environmentalism means, and to reuse for aquatic reasons.

In here, wastewater is first collected before it becomes transferred via water pumps to treatment plants. Filtration and treating contaminants will then come into a positioning role before the electropump sends it back into the system.

Pump Usage For Commercial Cleaning

To meet occupational hygiene, a self priming centrifugal jet pump is often utilised to keep grime, bacteria, and other residues away from your line of equipment. This is through a thorough cleanse down as the water pump shoots to clean up large instruments, conveyors and also the production floor, and as this is completed, your machines will remain in tiptop condition to run smoothly without fail – just as dirt becomes unstuck as gears and parts run smoothly.

Water Pump For Desalination

Applicable to both a desalination plant as well as a factory of making and supplying drinking water, the findings of reverse osmosis (RO) comes into play to purify hydration with the aid of Davey’s centrifugal pumps.

A semi-permeable membrane is installed into fabrication, which enables pure water molecules of h2o to permeate through, while blocking larger variants like salt and other chemical compounds with a pump forcing saline water in. During this process, the same strong pressure is needed to achieve the intended agenda, as RO goes against the natural gradient of osmosis itself. Meaning, the water pump would aid to flow water from a high solute concentration to a lower one. In fact, the very same principle may also be found across any water filter that uses RO as a principle.

Agriculture Irrigation

In the plowing agricultural fields, regardless of the weather a stable water supply is still needed, and especially so in Malaysia that is well-understood by Davey. It’s a vicinity of seasonal drought that comes from seasons to seasons, requiring a water pump for a multitude of usefulness to irrigate crops before the eventual rainfall. As different harvest vary in water consumption, these centrifugal pumps would manage efficiently in areas defined as ‘zones’ using an arrangement of irrigation system depending on consumption needs. For example, yields and fruits that drinks up more liquids would be grown in the same sector, which introduces a high flow rate of a water pump, whereas crops needing less are placed in the same zone with lesser spout.

Water Pump For Farming

A fresh and rejuvenative quench of hydration is always in demand for livestock, which is often gushed out into a watering trough using an electropump, and one that is extremely critical to maintain animal’s health and productivity. These water pumps for farming application offers clean supply of water, which is emphasised for daily survival, digestion, and regulating temperatures under the bask of the sun. And like cultivating crops, the growth rates for sheeps, poultry, and even cattle can be improved while reducing stress with just the mere aid of a water pump. Clean and newer source of hydration is always preferred, which is equally hygienic and also disease/illness-preventing as most centrifugal pumps release water directly from your state provider themselves. On the other hand, stagnant water, or water that is left exposed outside and under direct atmospheric ambience can bare bacteria and/or parasites under the absence of a water pump for circulation, which farm animals are often sensitive and become plagued to.

Better Pasture

Cows, goats, and even sheeps would benefit heartily out of grasses that are grown well, and this is achievable with a water pump for better irrigation across the hectares of fields. And it happens when hydration released by a hose, soaks up the range and the roots within would absorb the moisture, which is then transported internally via the xylem towards other parts of the pasture, nourishing for better growth. With hydration spread out by the centrifugal pump done, minerals are also dissolved into the earth can be absorbed better, ultimately giving greater nutritional value for the livestocks and poultry in the farm. This translates to superior wool, milk production, and even meat, signifying the end benefit of a water pump that led to extreme outcomes.

Fertigation With Water Pumps

One of the most exciting and revolutionising changes comes about in the duo aspects of drenching and using liquid fertilisation that can be mixed and then distributed evenly through a sprinkler system swirling across one’s garden, and also the farmer’s agricultural terrains, and of course, this is with Davey’s centrifugal pumps latched up to pressurise water for the fields. To begin, a fertiliser injector in the form of a positive displacement pump can be inserted into the trickle irrigation, and this jets out permeated sustenance for the yield. The spin-off of water pump and its technological system is a methodology of fertigation that allows for convenience, just as the automated spray relinquish manual labouring today.

Deep Well Pumping

Underground wells are reservoirs of groundwater far below the surface at depths of up to 50 meters that can be tapped into using Davey’s submersible pumps. As it is stored underneath, the water source remains free from evaporation and can be integrated into a water tank to supply into drip irrigation periods, and even for a drinking trough. The installed structure will eventually remain stable and will require fairly little maintenance at all, and this includes the submersible pump found. It should also be noted that a borewell pump can be specifically defined as a deep submersible pump here.

Installation

Depending on the intricacy of a stated project, the installation of a water booster pump can be conducted by either a plumbing professional, or a mechanical engineer at the site. This is because our pump operating manuals and installation procedure can be found upon every purchase, and likewise, a direct call towards Davey Malaysia and we can still offer support the same. However, it is still further advisable to call in a plumber from Davey’s list of authorised dealers, just as the individuals are equally taught, examined, and assessed from occasions to occasions about installing and using our own water pumps. Users are also welcome to clarify with Davey Malaysia to confirm if the retailer being sought-for is a legitimate and approved water pump merchant here, in order to prevent fraud and relatable incidents.

Inverter Pumps For Environmentalism

Outside of having the right-fit of a water pump to ensure that the operating limits are met equally, it is also an important hindsight to understand that stronger ones would consume even more electricity to generate stronger performances, and this may be counterproductive in real-world situations. And as much as it sounds irrational, having administer the wrong water pump across any industries at any moment tends to happen, whether through wrong consulting from third party or being given the inaccurate measurement, the resulting consequences lean towards underpowered or further-than-your-regular upsized centrifugal pumps.

This misdiagnosis is often costly and a misrepresentation for what utility bills will eventually charge. Whenever a water pump is found underperforming, an immediate address to change for anew takes place, whereas the overwhelming ones would imminently damage the piping system. In the household sector, an inverter water pump is the best recommendation in performance thus far. This is because every inverter water pump comes with the attachment of a variable-speed drive that would automatically adjust itself by running more impellers depending on the number of opened faucets, shower heads, as well as toilet usage found. As less parts are active, this equates to using less current, making this variation of water pump all the more eco-friendly with lesser greenhouse emission output.

As of recent trends, the upbringing of a separated adjustable-speed drive has been seen attached onto pump sets. In systems like the vertical multistage, the combo VSD-water pump are then installed into condos and/or apartments to be incredibly sustainable.

Spare Parts

Each of Davey’s water pump may be featured with different spare part complexity, and this can definitely vary in sizing. With dedicated components found, users would have to notify us of the pump’s identifier in order to retrieve the accurate components. All of the replacement parts have been trialed and tested for regulatory means, and this is labelled on the petroleum / electropump accurately for the public consumer to look upon the clauses, which may include materials leeching for the safety of drinking water, to electrocution discharge, and many more. For pump maintenance, core replacements can include the radial volute, pressure switch, the shaft (as can be seen in the cross section), gasket, O-ring, pressure tank, the tube for venturi effect amid jet release, and others. It should also be shared that obsolete products would have its spare parts discontinued, encouraging users to advance forward into a more modernised water pump iteration available, where safety mechanisms to protect users or enhanced coverage to function a better flow rate can be seen.

Water Pump FAQs

How do I increase water pressure without a pump?

No water pressure can be increased without a pump.

This is because the sciences behind increasing it is absent, which is the driven rotor mechanism, or impeller, that is attached to the shaft that swirls any liquid centrifugally is not available.

How does a water pump work?

A centrifugal pump operates by rotating the shaft through motor rotation.

This drives the impellers, which altogether swirl to move the water through centrifugal force.

As movement becomes created, it further creates a suction to draw in more water through its inlet port, resulting in a continuous flow of hydration so long as a water source is available.

Having this said, there are also other water pump types that uses different methodologies to produce an output, such as a piston pump which employs a positive displacement, a venturi jet pump that utilises Bernoulli’s principle to create the vacuum needed and higher suction force, a diaphragm pump which reciprocates diaphragm movement to transfer water, and so forth and so on.

How do I install a water pump?

A water pump should installed at a lower level than the water tank as an ideal state.

This is because the continuous flow of water supply source prevents cavitation and ensures that it is always primed to prevent dry-running.

Other considerations such as spacing of the water pump, power supply points, and even the inclination of floor levelling must also be taken into account.

For better consultation kindly refer to Davey Malaysia’s product specialist or authorised distributor for free consultation.

What is a DC water heater pump?

A DC (Direct Current) powered pump, as the name implies, uses DC current as its power source either from a PV (PhotoVoltaic) panel or a battery.

DC-types of water pumps features a higher initial torque, lower operation noise and also lower electricity consumption due to its smaller motor build.

However, as mainstream power supply is AC (Alternating Current), DC water pumps are actually less common except when a smaller-sized, low noise, and low power consumption pump becomes desired.

Why is my water pump pressure low still?

Your water pump’s pressure can be low still is due to the resulting simultaneous usage of the pump.

Or, it may very well be that the existing water pump installed is also undersized for your housing, with a lower maximum meter in the head.

For further investigations, it is best to contact Davey Malaysia’s pump specialist for a technical consultation for your case.

Why does my water pump keep turning on and off?

When your water pump is in a cyclical routine of turning on and off continuously, it could be the consequence of insufficient water supply due to a clogged inlet which has stagnated your output.

Or, there can also be a leakage within the piping distribution system.

Why does my water pump keeps on running?

If your water pump continues to run despite not using it, there could be a possibility of a wrong cut-in and/or out pressure amid an improper set-up.

Likewise, there could also be chances that your digital / analogue pressure controller is faulty / malfunctioned.

Where do I install a check valve on my water pump?

A check valve is installed on both the before and after sides of a water pump.

Whenever you’re installing it prior to the pump itself, please ensure that there is sufficient water reservoir to prime.

The positioning is done so that on the event if water hammering does occur, the pressure surged will not reach the internal part of the h2o pump to avoid catastrophic damages.

How do I remove an airlock in any water pump?

To remove an airlock across any types of water pump, be reminded that all fittings or valve must not be loosely connected.

Then, let the pump run for a period of time to purge any remaining air out of the piping system.

What do I do if my water pump keeps on running?

If so happens that your water electropump continuously run, for basis troubleshooting purposes, please turn off all water valve / outlet points available for the time being.

Should the issue persist, then you might have to audit for leaky piping system or even inspect for a faulty water pump’s sensing.

You are also equally free to reach out to our technical team for professional advice.

How do I tell if my water pump becomes bad?

You can tell your water pump becomes bad if there are signs like a drop in water pressure, odd and unusual sounds from the centrifugal pump, fluctuation in water pressure / flowrate, or even an increased in electrical consumption as found in your utility bill.

Preventing this is another advisable fact by getting tried and tested water pumps from time-tested pump manufacturers, just so unexpected sudden failures can be prevented.

How do I reduce my water pump noise?

A good water pump cover may aid to reduce its noise. Or, the inclusion of rubber pads to damper the vibrations can achieve the same conditioning too.

Yet, there are various other pump types that functions with greater quiet operation.

In any given, one of the best piece of advice Davey Malaysia has to offer is that it is still far better to select the right model for your situational fit than trying to remedy an issue with a unsuitable pump.

If it is a newly install water pump, then please ensure that it’s installed by an authorised specialist.

Proper installation technique and precaution is essential to prevent excessive disturbance, like rubber padding to damping the vibrations, proper fittings of bolt and nuts according to manufacturer’s torque advice, as well as others.

How do I repair my water pump?

Any water pump’s repairing process begins by diagnosing the root cause analysis of faulty components, or parts, to which it is then determined if it can be replaced with a new replacement or is deemed unrepairable.

Possible defected or broken parts can include the motor, impellers, mech-seals, shaft, capacitors, clogged valve, bad installations, worn-out O-rings / gasket, wear and tear of existing parts or more.

How do I check if my warranty is still eligible for my water pump?

To check if your water pump is still entitled for a warranty, please reach out to our customer support team with a proof of purchase for assistance.